Lithium battery wire welding technology

The selection and use of wires are very critical in the manufacture of lithium batteries. Currently, one of the most commonly used welding methods is done by laser welding.

Method:

Use laser to corrugate the two ends of the wire first, then pre-drill holes on the electrode sheet, pass the wire handle through the hole, and finally weld the wire and the electrode sheet together with a laser.

Precautions:

- Select the appropriate wire diameter and material. When selecting a wire, it is necessary to consider its conductivity and whether it meets the requirements of lithium battery manufacturing.

-The laser temperature should be adjusted according to the wire material. Wires of different materials have different soldering temperatures, which need to be adjusted according to specific conditions.

- The laser welding time should not be too long to avoid deformation of the wire and weaken the mechanical strength.

Latest News

-

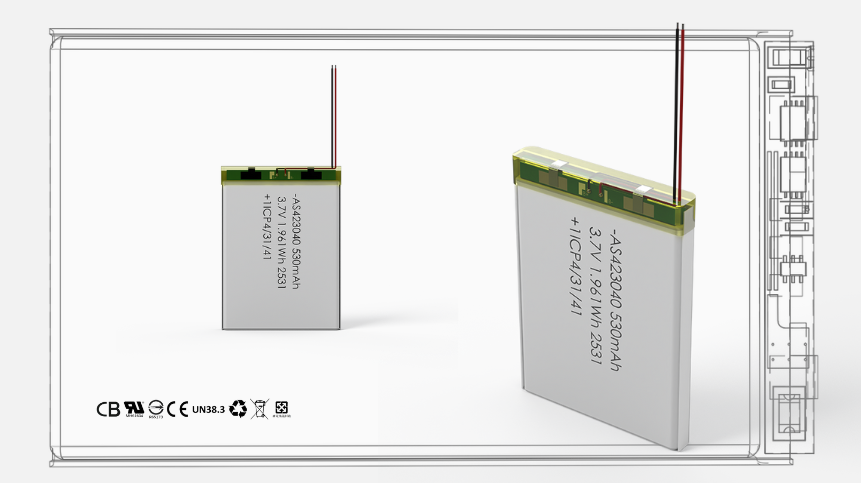

May.2025.09.08AS423040 3.7V 530mAh Li-Ion Polymer Battery – Compact, Certified, and ReliableLearn More

May.2025.09.08AS423040 3.7V 530mAh Li-Ion Polymer Battery – Compact, Certified, and ReliableLearn More -

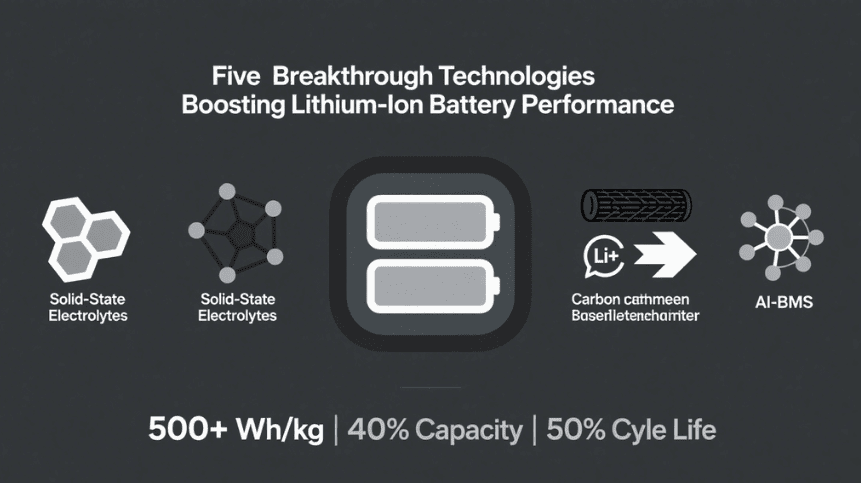

May.2025.09.04Five Breakthrough Technologies Boosting Lithium-Ion Battery PerformanceLearn More

May.2025.09.04Five Breakthrough Technologies Boosting Lithium-Ion Battery PerformanceLearn More -

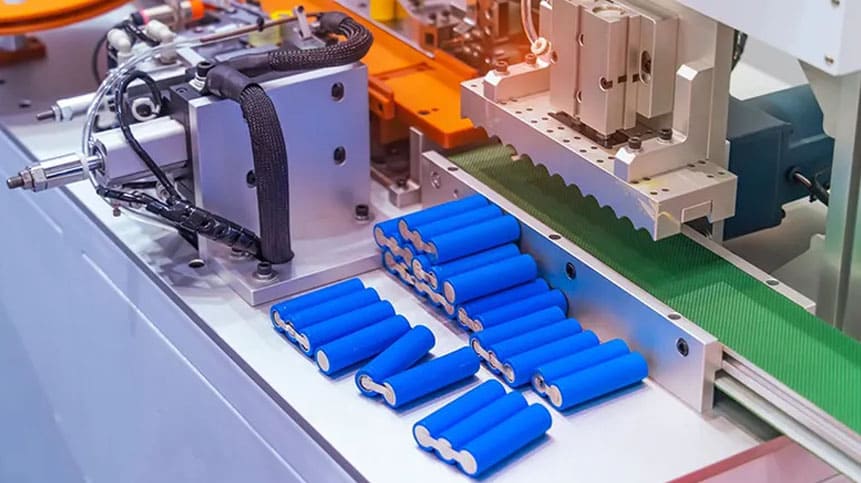

May.2025.09.02Lithium-ion Battery Pack Design and ProcessLearn More

May.2025.09.02Lithium-ion Battery Pack Design and ProcessLearn More -

May.2025.08.25Battery Certification Guide: Process, Timeline & The Value of an Expert PartnerLearn More

May.2025.08.25Battery Certification Guide: Process, Timeline & The Value of an Expert PartnerLearn More -

May.2025.08.19Temperature and Resistance Characteristics of Lithium-Ion BatteriesLearn More

May.2025.08.19Temperature and Resistance Characteristics of Lithium-Ion BatteriesLearn More

Contact Us