5 minutes to get the basics of the lithium battery PACK

The process of assembly of lithium battery cells is called PACK, which can be a single battery or a series and parallel battery module.Under the background of the new national standard, the demand for lithium battery is increasing, and many lead-acid battery enterprises have launched lithium battery products.In fact, it is not difficult to master the lithium battery PACK technology, which can assemble the battery itself instead of merely acting as the "battery carrier" for manufacturers, and the profit and after-sales service are no longer controlled by others.

PACK constitute:

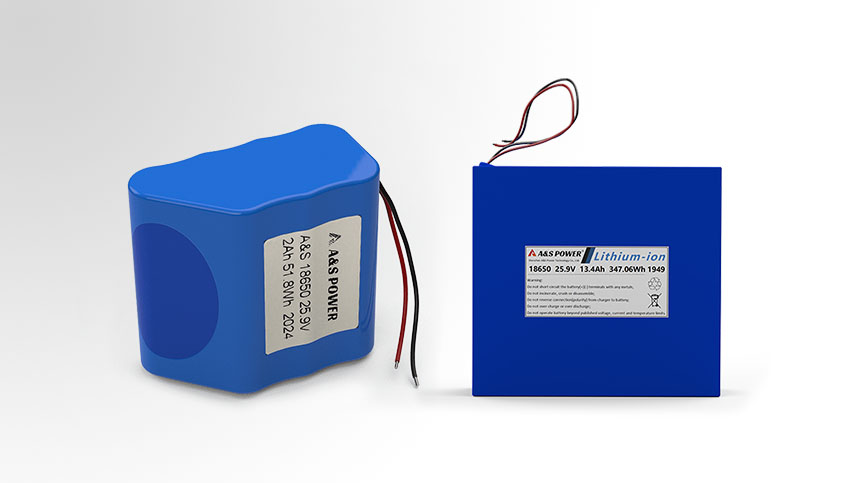

Pack includes battery PACK, bus bar, soft connection, protection plate, outer package, output (including connector), highland barley paper, plastic support and other auxiliary materials.

The characteristics of the PACK

(1) the battery PACK requires the battery to have a high degree of consistency (capacity, internal resistance, voltage, discharge curve, life).

The cycle life of the battery PACK is lower than that of a single battery.

(3) in the limited conditions of use (including charging, discharge current, charging mode, temperature, etc.)

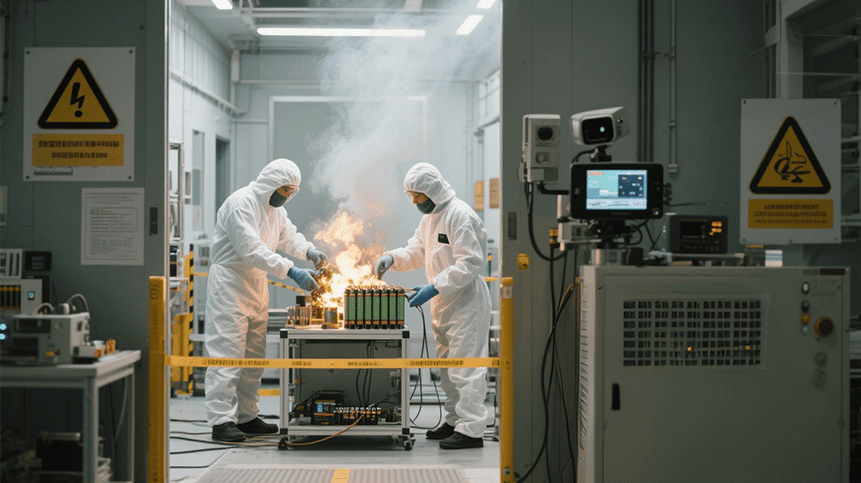

(4) after the formation of lithium battery PACK, battery voltage and capacity has been greatly improved, must be protected, charge balance, temperature, voltage and overcurrent monitoring.

The battery PACK must meet the design requirements of voltage and capacity.

The method of PACK

(1) string and composition: the battery by the single battery through and series. Parallel connection increases the capacity, the voltage remains unchanged, and the voltage multiplies after series connection, the capacity remains unchanged. For example, 3.6v /10Ah battery is composed of a single n18650/2ah through 5 parallel connections. Parallel before series: parallel because of the difference in internal resistance, heat dissipation will affect the parallel battery cycle life. But a single battery failure automatic exit, in addition to the capacity reduction, does not affect the use of parallel, parallel process is strict. When a unit battery in parallel is short-circuited, the current in the parallel circuit is very large, which is usually avoided by fusing protection technology. First in series and then in parallel: according to the battery capacity of the whole group, first in series, such as 1/3 of the battery capacity of the whole group, and finally in parallel, which reduces the failure probability of the large-capacity battery.

(2) cell requirements: according to their own design requirements to select the corresponding cell, parallel and series battery requirements type consistent, consistent, capacity, internal resistance, voltage difference is not more than 2%. In general, when batteries are combined in parallel series, the capacity loss is 2% to 5%. The more batteries, the more capacity loss. Both flexible pack batteries and cylindrical batteries require multiple series of combinations. If poor consistency affects the battery capacity, the battery with the lowest capacity in a group determines the capacity of the whole battery group. High current discharge performance is required. The starting current of the motor is 3 times of the normal working current. Good heat dissipation of battery is required. Due to the large number of batteries, the temperature rise of the battery in the battery box is not easy to come out, which results in uneven temperature and different discharge characteristics among the batteries. As a result, the battery performance decreases for a long time. High level of production technology. The battery should be able to withstand the vibrations of a bumpy road. It has high requirements on production process especially spot welding process. After the completion of welding test to prevent virtual welding, off welding.

(3) Battery PACK is realized in two ways, one is by laser welding or ultrasonic welding or pulse welding, which is a commonly used welding method, the advantage of good reliability, but not easy to replace.The second is through the elastic metal sheet contact, advantage is no need for welding, battery replacement is easy, disadvantage is may lead to poor contact.

-

May.2025.07.232025 Latest Lithium Polymer Battery Product Certification Form - A&S PowerLearn More

May.2025.07.232025 Latest Lithium Polymer Battery Product Certification Form - A&S PowerLearn More -

May.2025.07.22Operation of Lithium-Ion Batteries in Medical DevicesLearn More

May.2025.07.22Operation of Lithium-Ion Batteries in Medical DevicesLearn More -

May.2025.07.17Safety Analysis of Lithium Batteries: How to Prevent Overheating and MalfunctionsLearn More

May.2025.07.17Safety Analysis of Lithium Batteries: How to Prevent Overheating and MalfunctionsLearn More -

May.2025.07.11Finished Product Testing of Lithium-Ion Batteries and Its ImpactsLearn More

May.2025.07.11Finished Product Testing of Lithium-Ion Batteries and Its ImpactsLearn More -

May.2025.07.08How to Choose the Right Lithium Battery for You: A Comprehensive GuideLearn More

May.2025.07.08How to Choose the Right Lithium Battery for You: A Comprehensive GuideLearn More