Battery Internal Resistance Testing

Battery Internal Resistance Testing: Methods, Importance & Applications

Battery internal resistance testing is of great significance in evaluating the performance, health status, and safety of batteries. It provides crucial information for battery manufacturers, researchers, and end-users in various applications, from consumer electronics to electric vehicles.

What is Battery Internal Resistance?

Internal resistance represents the opposition to the flow of electric current within a battery. It consists of ohmic resistance (caused by the physical materials and components) and polarization resistance (related to electrochemical reactions). A lower internal resistance generally indicates better battery performance, higher power delivery capabilities, and longer cycle life.

Monitoring changes in internal resistance over time helps detect early signs of battery degradation, such as electrode aging, electrolyte drying, or internal short-circuits.

Common Methods of Internal Resistance Testing

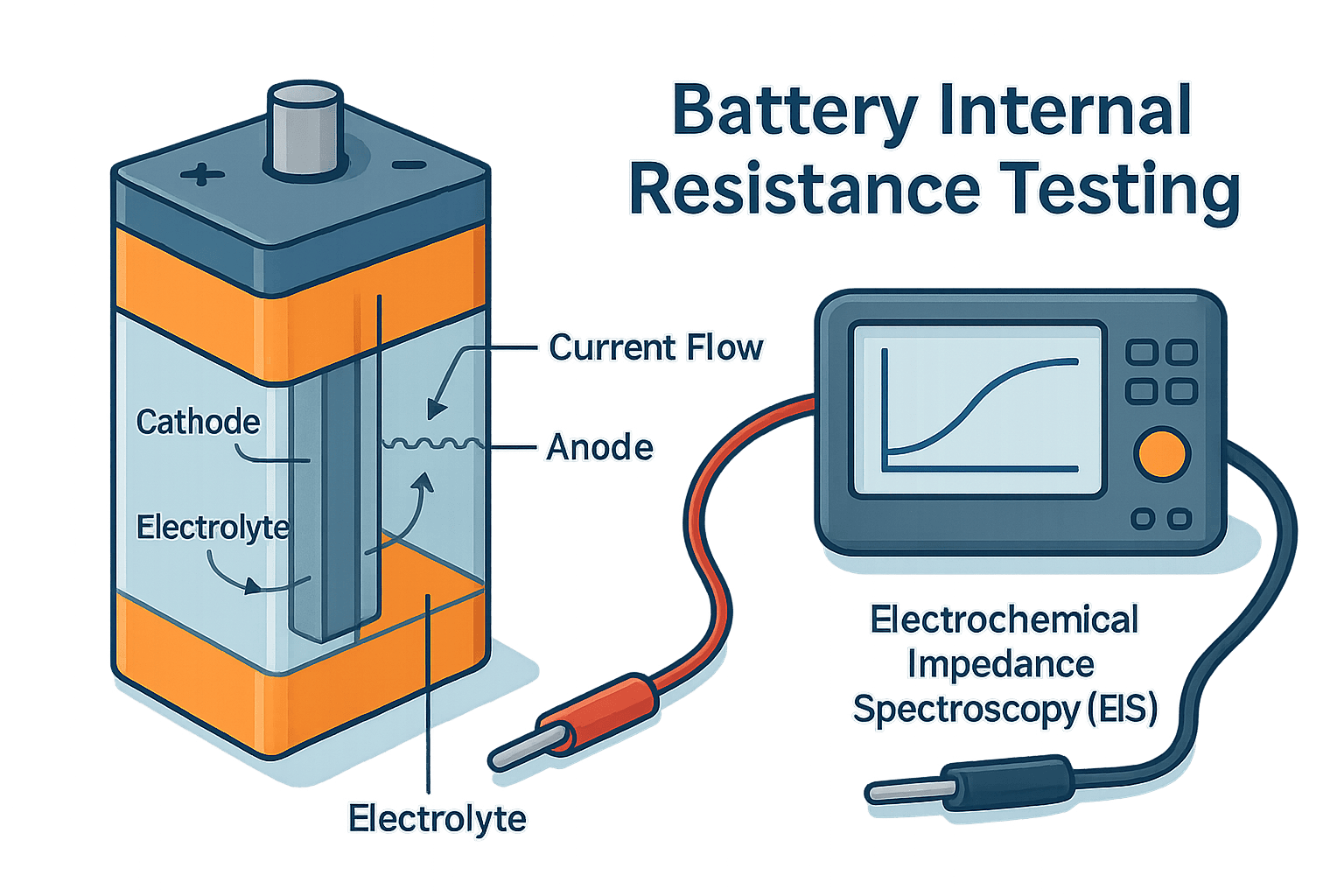

1. Electrochemical Impedance Spectroscopy (EIS)

One of the most popular techniques is electrochemical impedance spectroscopy (EIS). EIS applies a small-amplitude AC signal to the battery at different frequencies and measures the resulting voltage response. By analyzing the impedance spectrum, detailed information about the battery's internal resistance components, including charge-transfer resistance and diffusion resistance, can be obtained.

This method offers high accuracy and comprehensive insights, though it may require complex equipment and longer measurement times. Learn more on BioLogic.

2. DC Discharge Method

Another widely-used approach is the DC discharge method. It involves applying a constant DC load to the battery and measuring the voltage drop across the terminals. The internal resistance is then calculated using Ohm's Law. This method is simple, cost-effective, and ideal for quick on-site assessments.

However, it may introduce errors due to the battery's transient response during discharge and only provides an overall resistance value.

How to Test Battery Internal Resistance Using DC Discharge

- Ensure the battery is in a stable state with a known state of charge.

- Connect the battery to a DC load with precisely controlled current.

- Use high-precision instruments to record the voltage before and during discharge.

- Calculate internal resistance by dividing the voltage drop by discharge current.

Applications and Importance

In electric vehicles, regular internal resistance monitoring helps optimize the battery management system (BMS), improve vehicle performance, and extend battery life.

For backup power systems, it ensures reliable power supply during outages by detecting weak batteries early. In R&D of new battery technologies, it provides essential data for evaluation and improvement.

Conclusion

Battery internal resistance testing is essential for understanding battery behavior and ensuring reliability. Different methods have their unique advantages and should be chosen based on accuracy, cost, and time requirements.

As battery technologies continue to evolve, the need for accurate and efficient internal resistance testing will only grow in importance.

-

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More -

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More -

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More -

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More -

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More