Lithium ion problem causes’ analysis and solution (1)

Lithium Ion Problem Causes' Analysis and Solution (1)

Introduction to Lithium-Ion Battery Challenges

The global energy storage landscape has undergone revolutionary transformation through lithium-ion battery technology, which now powers everything from portable electronics to electric vehicles and grid-scale storage systems. Despite their widespread adoption and technological advancements, these energy storage devices continue to face significant challenges that impact their performance, safety, and longevity. Industry reports indicate that while lithium-ion batteries maintain approximately 85% market share in rechargeable battery sectors, they simultaneously account for 67% of documented energy storage safety incidents worldwide. The fundamental issues plaguing these systems range from inherent chemical instability to manufacturing inconsistencies and operational limitations that collectively undermine their theoretical potential. Understanding these challenges requires comprehensive examination across multiple dimensions including material science, electrochemical processes, thermal management, and real-world application scenarios that reveal the complex interplay between battery components and their operating environments.

Current research demonstrates that even premium-grade lithium-ion cells experience performance degradation that begins from their first operational cycle, with average capacity fade rates of 2-3% per hundred cycles under optimal conditions. These degradation mechanisms accelerate dramatically under suboptimal conditions, with high-temperature environments (above 40°C) potentially doubling degradation rates and high-current operations potentially tripling capacity loss. The financial implications are substantial, with premature battery replacement costing the electric vehicle industry an estimated $2.3 billion annually and causing approximately 15% of warranty claims across energy storage sectors. These challenges have stimulated massive research and development initiatives aimed at understanding root causes and developing effective mitigation strategies that address both technical limitations and economic considerations.

Primary Technical Limitations and Failure Modes

Electrochemical Degradation Mechanisms

The fundamental operation of lithium-ion batteries involves complex electrochemical processes that inevitably lead to performance degradation over time. During charging and discharging cycles, lithium ions move between cathode and anode through electrolyte medium, causing gradual structural changes in electrode materials. Cathode materials particularly nickel-manganese-cobalt (NMC) formulations experience lattice instability and transition metal dissolution at higher voltages, with studies showing approximately 1.2% cobalt dissolution after 500 cycles at 4.3V operation. This dissolution leads to active material loss and subsequent capacity reduction while simultaneously contaminating electrolyte and compromising anode integrity. The situation exacerbates at elevated temperatures where dissolution rates increase exponentially, creating a vicious cycle of accelerated degradation that ultimately manifests as reduced runtime and power capability.

Anode materials face different but equally challenging degradation pathways, with graphite electrodes suffering from solid electrolyte interphase (SEI) layer growth that consumes active lithium ions and increases internal resistance. This SEI formation, while necessary for initial stability, continues throughout battery life with layer thickness increasing from initial 20-50nm to over 200nm after extensive cycling, corresponding to approximately 15-20% capacity loss. Silicon-containing anodes, despite their higher capacity, experience dramatic volume changes exceeding 300% during lithiation/delithiation processes that cause particle fracture and loss of electrical contact. These mechanical stresses combine with chemical degradation to create complex failure modes that require sophisticated mitigation strategies including advanced binder systems, nanostructured materials, and surface stabilization technologies.

Thermal Management Challenges

Lithium-ion batteries operate within remarkably narrow temperature ranges, with optimal performance occurring between 15-35°C and significant degradation occurring outside this window. At temperatures below 0°C, ionic conductivity decreases substantially while charge transfer resistance increases dramatically, leading to lithium plating phenomena that permanently reduce capacity and compromise safety. Research indicates that charging at -10°C can cause up to 12% permanent capacity loss in a single cycle due to metallic lithium deposition on anode surfaces. High-temperature operation above 45°C accelerates parasitic reactions including SEI growth, electrolyte decomposition, and active material degradation that collectively reduce cycle life by approximately 40% for every 10°C increase above optimal temperature range.

The thermal management challenge becomes particularly critical in high-power applications where heat generation during operation can rapidly elevate internal temperatures. Electric vehicle fast charging at 2C rates or higher can generate sufficient heat to raise battery temperature by 15-20°C within minutes, creating conditions that accelerate degradation and potentially trigger thermal runaway. Contemporary battery systems incorporate sophisticated thermal management systems including liquid cooling plates, phase change materials, and advanced thermal interface materials that maintain temperature uniformity within 2-3°C across entire battery packs. Despite these advancements, thermal management remains a significant challenge that accounts for approximately 25% of system cost and 15% of pack weight in modern electric vehicle batteries.

Voltage and Current Limitations

The operational voltage window of lithium-ion batteries represents a critical compromise between energy density and longevity. While higher upper cut-off voltages increase available energy, they simultaneously accelerate degradation through electrolyte oxidation and cathode material instability. Research demonstrates that increasing NMC811 cathode voltage from 4.2V to 4.4V provides approximately 15% higher energy density but reduces cycle life by nearly 50% due to accelerated structural degradation and gas generation. Similarly, deep discharge below recommended voltages can cause copper current collector dissolution that permanently damages battery performance and creates safety hazards through internal short circuit formation.

Current limitations present another fundamental constraint, with high charge and discharge rates causing concentration polarization that leads to lithium plating and accelerated degradation. Rapid charging above 1C rate increases the risk of lithium dendrite formation, particularly at lower states of charge and colder temperatures where anode potential more readily drops below lithium deposition threshold. The industry standard 1C rating itself represents a compromise between convenience and longevity, with studies showing that continuous 2C operation can reduce cycle life by approximately 60% compared to 0.5C operation. These limitations have driven development of advanced charging algorithms that dynamically adjust rates based on temperature, state of charge, and battery health to optimize both charging speed and long-term performance.

Manufacturing and Quality Control Issues

Electrode Production Challenges

The manufacturing process for lithium-ion batteries involves numerous precision steps where minor variations can significantly impact final performance and reliability. Electrode coating represents one of the most critical processes, where slurry containing active materials, conductive additives, and binders must be applied with exceptional uniformity to ensure consistent current distribution and lithium-ion transport. Thickness variations exceeding 2% can create localized hot spots during operation that accelerate degradation and potentially cause safety issues. Calendering process that follows coating must achieve precise porosity control, with optimal values typically between 30-35% for cathodes and 35-40% for anodes to balance energy density and power capability while maintaining structural integrity.

Drying processes present additional challenges where too rapid solvent removal can cause binder migration that creates inhomogeneous electrode structure with reduced adhesion and increased resistance. Industrial manufacturing must maintain production speeds exceeding 80 meters per minute while achieving coating weight tolerances within ±1.5% and thickness uniformity within ±2 micrometers. These requirements demand sophisticated control systems and real-time monitoring technologies that can detect and correct deviations before they impact product quality. Despite these advancements, manufacturing variations remain a significant contributor to performance spread among cells from the same production batch, with capacity variations typically ranging between 2-5% even for premium-grade cells.

Assembly and Formation Complications

Cell assembly introduces multiple potential failure points including electrode misalignment, separator wrinkling, and contamination that can compromise performance and safety. Even microscopic metal particles introduced during manufacturing can create internal short circuits that lead to self-discharge or thermal runaway. The precision required in electrode stacking or winding processes demands cleanroom environments with strict humidity control (typically below 1% dew point) to prevent moisture absorption that would cause electrolyte decomposition and gas formation during operation.

Formation cycling represents one of the most critical and time-consuming steps in battery manufacturing, where initial charge-discharge cycles activate the battery by forming stable SEI layers on anode surfaces. This process typically requires 3-7 days and consumes approximately 5-8% of factory energy consumption while adding significant capital cost through specialized equipment requirements. Inadequate formation can lead to unstable SEI layers that continue growing during normal operation, consuming electrolyte and active lithium while increasing resistance. Optimization of formation protocols has become a major focus for manufacturers seeking to reduce costs and improve consistency, with advanced algorithms using real-time monitoring and adaptive control showing potential to reduce formation time by 30% while improving performance consistency.

Material Limitations and Supply Chain Challenges

Cathode Material Constraints

Current cathode technologies face fundamental limitations that restrict further performance improvements while raising concerns about material sustainability and cost. High-nickel NMC formulations (NMC811, NMC955) offer higher energy density but suffer from reduced thermal stability and shorter cycle life compared to lower-nickel alternatives. The nickel content increase improves specific capacity but accelerates degradation through enhanced surface reactivity and structural instability during cycling. Cobalt-containing cathodes face ethical and supply chain challenges with approximately 70% of global cobalt production originating from the Democratic Republic of Congo under questionable labor conditions, while price volatility has seen cobalt prices fluctuate by over 300% in recent years.

Lithium iron phosphate (LFP) cathodes have gained popularity due to their excellent safety characteristics and long cycle life but suffer from lower energy density and poor low-temperature performance. The volumetric energy density of LFP batteries remains approximately 30% lower than advanced NMC formulations, limiting their application in space-constrained applications. Manganese-rich cathodes offer potential cost and safety advantages but face challenges with manganese dissolution that accelerates capacity fade, particularly at elevated temperatures. These material limitations have driven research into alternative cathode chemistries including disordered rock salt structures, lithium-rich layered materials, and cobalt-free compositions that promise higher performance without critical material dependencies.

Anode Material Development

Graphite anodes have dominated lithium-ion technology for decades but approach their theoretical capacity limit of 372 mAh/g, creating a fundamental barrier to energy density improvements. Silicon-based anodes offer substantially higher theoretical capacity (3579 mAh/g for pure silicon) but suffer from extreme volume expansion during lithiation that causes particle fracture and loss of electrical contact. Commercial silicon-carbon composites typically contain 5-10% silicon content, providing capacity improvements of 20-30% over graphite while maintaining reasonable cycle life. Higher silicon content anodes require sophisticated nanostructuring and advanced binder systems that increase manufacturing complexity and cost.

Lithium metal anodes represent the ultimate solution with theoretical capacity of 3860 mAh/g and lowest electrochemical potential, but face severe challenges with dendrite formation and low Coulombic efficiency. Dendrite growth during cycling creates short circuit risks and consumes electrolyte through continuous SEI formation, typically limiting cycle life to fewer than 100 cycles in practical cells. Numerous approaches including artificial SEI layers, solid electrolytes, and three-dimensional host structures have shown promise in laboratory settings but face significant scaling challenges for commercial implementation. The anode development landscape remains highly active with new materials including lithium titanium oxide (LTO), tin-based composites, and conversion materials offering alternative pathways to improved performance.

Performance Degradation in Real-World Applications

Electric Vehicle Specific Challenges

The automotive environment presents particularly challenging conditions for lithium-ion batteries, combining high power demands, wide temperature variations, and long service life requirements. Electric vehicle batteries typically experience capacity fade of 2-3% per year under normal operating conditions, with accelerated degradation occurring in extreme climates and high-utilization scenarios. Rapid acceleration and regenerative braking create high current pulses that stress electrode materials and accelerate degradation, particularly at state of charge extremes where material stability decreases. Thermal cycling between day and night temperatures causes mechanical stress through differential expansion of battery components, potentially leading to delamination and increased resistance.

The combination of calendar aging and cycle aging creates complex degradation patterns that vary significantly based on usage patterns and environmental conditions. Vehicles in hot climates like Arizona and Saudi Arabia experience approximately 50% faster capacity loss compared to moderate climates like Germany and Japan, primarily due to accelerated SEI growth at elevated temperatures. High-mileage vehicles such as taxis and delivery vans face additional cycle life challenges, with commercial vehicles typically requiring battery replacement after 3-5 years compared to 8-10 years for personal vehicles. These real-world degradation patterns have significant implications for warranty costs, residual values, and total cost of ownership that influence consumer adoption and industry profitability.

Grid Storage and Stationary Applications

Stationary energy storage systems face different challenges related to continuous operation, large system sizes, and economic considerations. While generally experiencing less severe cycling conditions than automotive applications, grid batteries must maintain performance over 15-20 year service lives with minimal maintenance and maximum reliability. The typically shallow cycling patterns (often 10-30% depth of discharge) reduce mechanical stress but create unique degradation mechanisms including time-dependent capacity fade and power capability reduction. Large system sizes magnify small variations between cells, creating balance issues that reduce usable capacity and increase management complexity.

Thermal management represents a particular challenge for containerized grid storage systems where high energy density and limited space create cooling difficulties. Despite active thermal management systems, temperature variations within large battery racks can exceed 5°C, leading to divergent aging patterns that reduce overall system performance. Economic pressures favor minimizing system costs through reduced cooling capacity and simpler battery management systems, creating trade-offs between initial investment and long-term performance. These challenges have driven development of specialized battery designs for stationary applications that prioritize longevity and safety over energy density, often using LFP chemistry and conservative operating parameters.

Emerging Solutions and Future Directions

Advanced Material Developments

The research community continues to develop innovative materials that address fundamental limitations of current lithium-ion technologies. Solid-state electrolytes represent perhaps the most promising advancement, offering improved safety through elimination of flammable liquid electrolytes and enabling use of lithium metal anodes for higher energy density. Sulfide-based solid electrolytes demonstrate ionic conductivity exceeding 10⁻² S/cm at room temperature, comparable to liquid electrolytes, while oxide-based systems offer superior stability against lithium metal. Challenges remain regarding interface resistance, manufacturing scalability, and cost, with commercial solid-state batteries expected to reach markets in limited quantities within 2-3 years.

High-capacity cathode materials including nickel-rich layered oxides (LiNi₀.₉Mn₀.₀₅Co₀.₀₅O₂), lithium-rich layered oxides (xLi₂MnO₃·(1-x)LiMO₂), and disordered rock salt compounds offer substantial improvements in energy density while reducing cobalt content. These materials typically deliver capacities exceeding 250 mAh/g compared to 180-200 mAh/g for current NMC materials, potentially increasing cell energy density by 20-30%. Implementation challenges include voltage fade, gas generation, and structural instability that require sophisticated doping strategies, surface coatings, and electrolyte formulations to overcome. The development timeline for these advanced cathodes suggests commercial availability within 3-5 years for premium applications followed by broader adoption as manufacturing processes mature.

Manufacturing Innovations

Advanced manufacturing technologies promise to improve consistency, reduce costs, and enable new battery designs that overcome current limitations. Dry electrode processing represents a revolutionary approach that eliminates solvent use in electrode fabrication, reducing energy consumption by approximately 40% while enabling thicker electrodes with improved performance. The technology, pioneered by Maxwell Technologies (now part of Tesla), uses fibrillized binders that create self-supporting electrode films without traditional solvent casting and drying processes. This approach facilitates production of electrodes with higher active material content (potentially exceeding 98%) and reduced porosity for improved energy density and power capability.

Additive manufacturing techniques including 3D printing enable complex electrode architectures with graded compositions and structured geometries that optimize lithium-ion transport and stress distribution. Printed battery designs demonstrate improved rate capability and cycle life through tailored porosity and channel structures that reduce diffusion limitations and accommodate volume changes. These advanced manufacturing approaches remain primarily at laboratory scale but show promise for specialized applications where performance outweighs cost considerations. The manufacturing innovation landscape continues to evolve rapidly with numerous technologies approaching commercial viability that could transform battery production within the next decade.

Comparative Performance of Current and Emerging Battery Technologies

| Technology | Energy Density (Wh/kg) | Cycle Life (cycles) | Cost ($/kWh) | Safety | Commercial Availability |

|---|---|---|---|---|---|

| NMC Graphite | 250-300 | 1000-2000 | 120-150 | Moderate | Current |

| LFP Graphite | 160-220 | 3000-6000 | 90-120 | High | Current |

| Solid-State | 300-400 | 1000+ | 200-300 (projected) | Very High | 2025-2026 |

| Silicon Dominant | 300-350 | 500-800 | 150-200 | Moderate | 2024-2025 |

| Lithium Metal | 400-500 | 100-300 (current) | N/A | Low (current) | 2026+ |

Conclusion and Path Forward

The lithium-ion battery industry stands at a critical juncture where technological innovation must address persistent challenges while supporting massive scale-up to meet growing demand. Current limitations including performance degradation, safety concerns, and material constraints require comprehensive solutions that span materials science, manufacturing technology, and system design. The ongoing transition to higher-nickel cathodes, silicon-composite anodes, and advanced electrolytes represents evolutionary improvement that extends existing technology while research continues on revolutionary approaches including solid-state batteries, lithium metal anodes, and alternative chemistries.

The path forward involves parallel development tracks addressing immediate needs while pursuing long-term breakthroughs. Near-term improvements focus on manufacturing refinement, thermal management optimization, and control algorithm advancement that maximize performance within existing material constraints. Medium-term developments include gradual introduction of silicon-rich anodes, cobalt-free cathodes, and solid-state electrolytes that offer step-change improvements in energy density and safety. Long-term research explores fundamentally new approaches including lithium-sulfur, lithium-air, and other beyond-lithium-ion technologies that promise order-of-magnitude improvements but face significant scientific and engineering challenges.

The successful navigation of these challenges will determine the pace of electrification across transportation, energy storage, and countless other applications that depend on advanced energy storage. Continued investment in research and development, coupled with close collaboration between academic institutions, industry partners, and government agencies, will accelerate progress toward safer, more efficient, and more affordable energy storage solutions. The ultimate goal remains the development of sustainable energy storage systems that support global decarbonization efforts while meeting the demanding requirements of diverse applications across the economic spectrum.

-

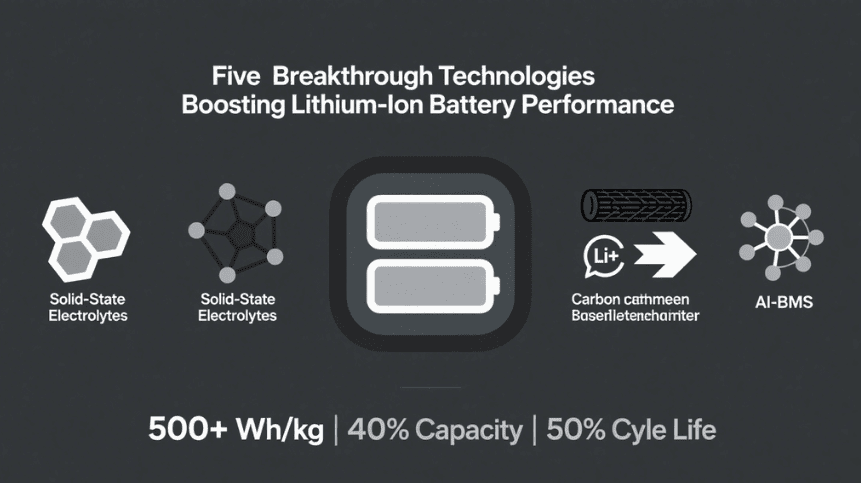

May.2025.09.04Five Breakthrough Technologies Boosting Lithium-Ion Battery PerformanceLearn More

May.2025.09.04Five Breakthrough Technologies Boosting Lithium-Ion Battery PerformanceLearn More -

May.2025.09.02Lithium-ion Battery Pack Design and ProcessLearn More

May.2025.09.02Lithium-ion Battery Pack Design and ProcessLearn More -

May.2025.08.25Battery Certification Guide: Process, Timeline & The Value of an Expert PartnerLearn More

May.2025.08.25Battery Certification Guide: Process, Timeline & The Value of an Expert PartnerLearn More -

May.2025.08.19Temperature and Resistance Characteristics of Lithium-Ion BatteriesLearn More

May.2025.08.19Temperature and Resistance Characteristics of Lithium-Ion BatteriesLearn More -

May.2025.08.1225.2 Volt 8.7 Ah Lithium Battery for the EV Rider Transport AF S19AF – Complete GuideLearn More

May.2025.08.1225.2 Volt 8.7 Ah Lithium Battery for the EV Rider Transport AF S19AF – Complete GuideLearn More