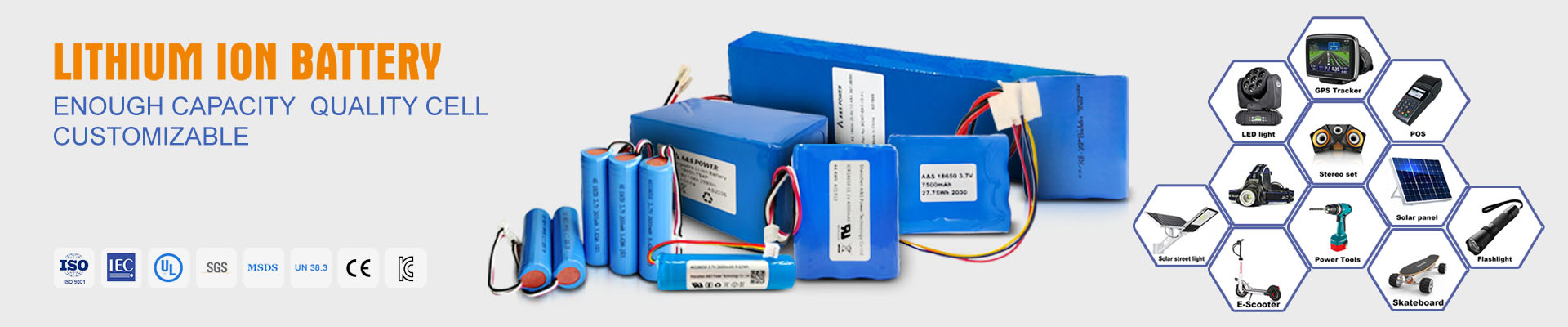

Battery

Application

Hot product

Contact us

What are the physical and chemical indexes and types of lithium ion battery diaphragm materials?

2023-05-12

What are the physical and chemical indexes and types of lithium ion battery diaphragm materials?

The function of lithium ion battery diaphragm paper in lithium ion battery is to isolate the positive and negative materials. The quality of diaphragm paper directly affects the safety performance and capacity of battery.

Using polyethylene and polypropylene as raw materials, the traditional polymer diaphragm materials were prepared by melting extrusion, stretching, thermal setting and other processes. The material has higher porosity and tear strength, better acid and alkali resistance and elasticity, and its physical and chemical properties have no obvious change after several hundred times of recycling.

Aperture size: Diaphragm has a certain aperture size, which can control the ion transfer rate between the positive and negative electrodes.

Aperture distribution: The size and distribution uniformity of the aperture in the diaphragm also have a significant impact on cell performance.

Conductivity: The diaphragm should have good conductivity to ensure the balanced distribution of charge inside the battery.

Mechanical strength: The diaphragm should have sufficient mechanical strength to prevent problems such as short circuit or pinhole inside the battery.

Chemical stability: The diaphragm should have enough chemical stability to ensure that the battery will not decompose, dissolve and other phenomena when running for a long time.

Common types of lithium ion battery diaphragm materials include polypropylene (PP), polyimide (PI), polyimide (PBI) and so on. Among them, polypropylene is the most commonly used lithium ion battery separator material, because of its low price, good chemical stability and so on, is widely used.

The function of lithium ion battery diaphragm paper in lithium ion battery is to isolate the positive and negative materials. The quality of diaphragm paper directly affects the safety performance and capacity of battery.

Using polyethylene and polypropylene as raw materials, the traditional polymer diaphragm materials were prepared by melting extrusion, stretching, thermal setting and other processes. The material has higher porosity and tear strength, better acid and alkali resistance and elasticity, and its physical and chemical properties have no obvious change after several hundred times of recycling.

Aperture size: Diaphragm has a certain aperture size, which can control the ion transfer rate between the positive and negative electrodes.

Aperture distribution: The size and distribution uniformity of the aperture in the diaphragm also have a significant impact on cell performance.

Conductivity: The diaphragm should have good conductivity to ensure the balanced distribution of charge inside the battery.

Mechanical strength: The diaphragm should have sufficient mechanical strength to prevent problems such as short circuit or pinhole inside the battery.

Chemical stability: The diaphragm should have enough chemical stability to ensure that the battery will not decompose, dissolve and other phenomena when running for a long time.

Common types of lithium ion battery diaphragm materials include polypropylene (PP), polyimide (PI), polyimide (PBI) and so on. Among them, polypropylene is the most commonly used lithium ion battery separator material, because of its low price, good chemical stability and so on, is widely used.