PCM vs BMS in Lithium Batteries: What’s the Difference and Which One Do You Need?

Lithium batteries remain one of the most important power sources for modern devices—from medical equipment and wearables to consumer electronics, drones, and industrial instruments. As energy density increases, so do the demands on battery safety, charge control, and real-time monitoring.

Two technologies are widely used to ensure safety and performance: the PCM (Protection Circuit Module) and the BMS (Battery Management System).

While many buyers assume PCM and BMS serve the same purpose, they are fundamentally different in architecture, intelligence, protection level, and application suitability. This article provides a comprehensive, engineering-level explanation with data tables, expert insights, and practical selection guidelines.

Introduction: Why Battery Protection Matters

Lithium-ion (Li-ion) and lithium-polymer (LiPo) cells require strict protection. Without proper management, they are vulnerable to:

-

Overcharging

-

Over-discharging

-

Over-current

-

Short circuits

-

Thermal runaway

According to UL1642 and IEC62133 data, over 60% of lithium battery failures are caused by inadequate protection architecture, particularly in low-cost consumer devices.

Selecting the right protection circuit is not only a safety requirement but also critical to product lifespan, performance consistency, and compliance for export markets such as the EU, US, Korea, and Japan.

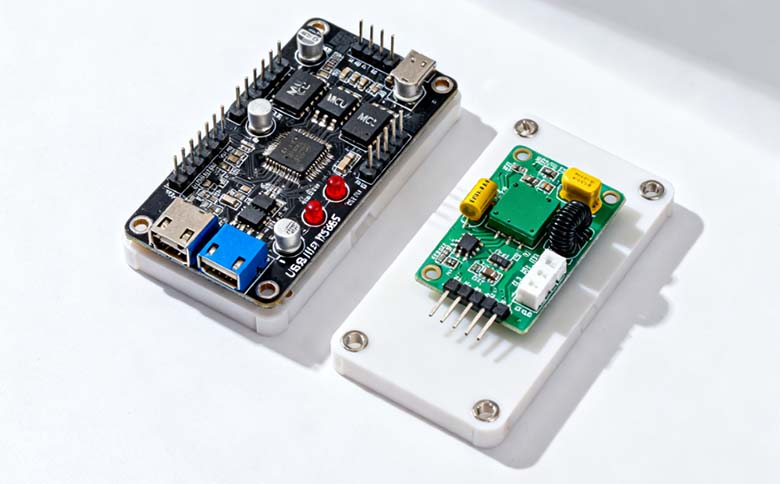

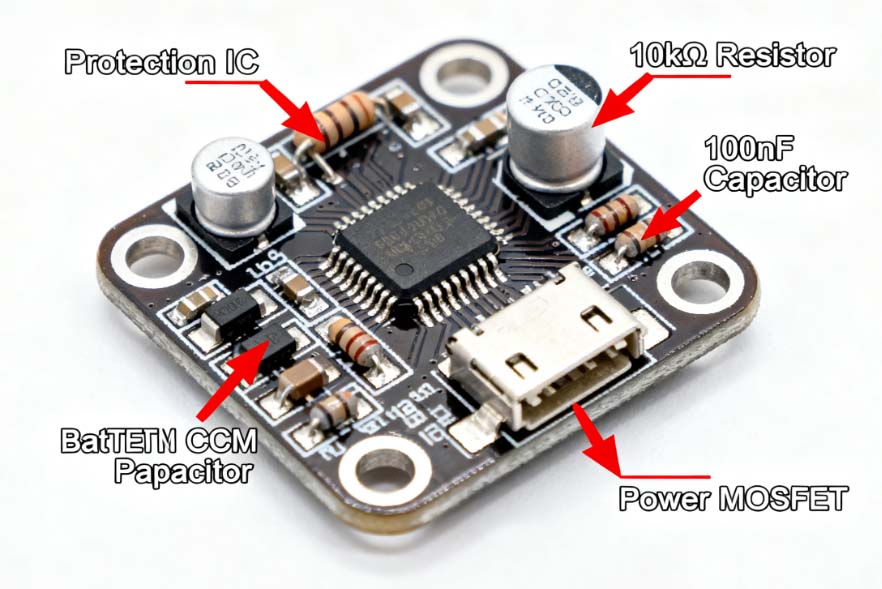

What Is a PCM (Protection Circuit Module)?

A PCM is the most basic protection system used in single-cell and small battery packs. Its primary job is to prevent catastrophic failure by cutting off the circuit when parameters exceed safe limits.

Core Functions of PCM

-

Over-charge protection

-

Over-discharge protection

-

Over-current protection

-

Short-circuit protection

-

Basic balancing (only on some multi-cell PCMs)

A PCM does not collect, record, analyze, or report battery data. Its function is passive protection, not active management.

What Is a BMS (Battery Management System)?

A BMS is an advanced, intelligent system used in larger, more complex battery packs. Beyond protection, it continuously monitors battery behavior and actively manages performance.

Core Functions of BMS

-

All PCM protection features

-

Cell balancing (active or passive)

-

SOC estimation (State of Charge)

-

SOH estimation (State of Health)

-

Temperature monitoring & control

-

Current & voltage sensing

-

Communication protocols (UART, I²C, SMBus, CAN, RS485, Bluetooth)

-

Fault logs & diagnostics

-

Charge optimization

-

Communication with host system

A BMS acts like a “brain” for the battery, while a PCM acts like a “safety switch.”

PCM vs BMS: Complete Comparison Table

Table 1: Core Differences Between PCM and BMS

| Feature / Function | PCM (Protection Circuit Module) | BMS (Battery Management System) |

|---|---|---|

| Main Purpose | Basic protection | Intelligent monitoring & management |

| Real-time Data | No | Yes |

| Cell Balancing | Limited or none | Standard (active/passive) |

| Communication | None | UART / CAN / SMBus / Bluetooth |

| SOC Estimation | No | Yes |

| SOH Estimation | No | Yes |

| Temperature Sensors | Usually 0–1 | Multiple (NTC/thermistors) |

| Suitable Battery Type | Single cell or small packs | Multi-cell packs (2S–45S+) |

| Application Complexity | Low | Medium to high |

| Cost | Low | Medium to high |

| Export Compliance | May need additional safeguards | Meets most high-level compliance standards |

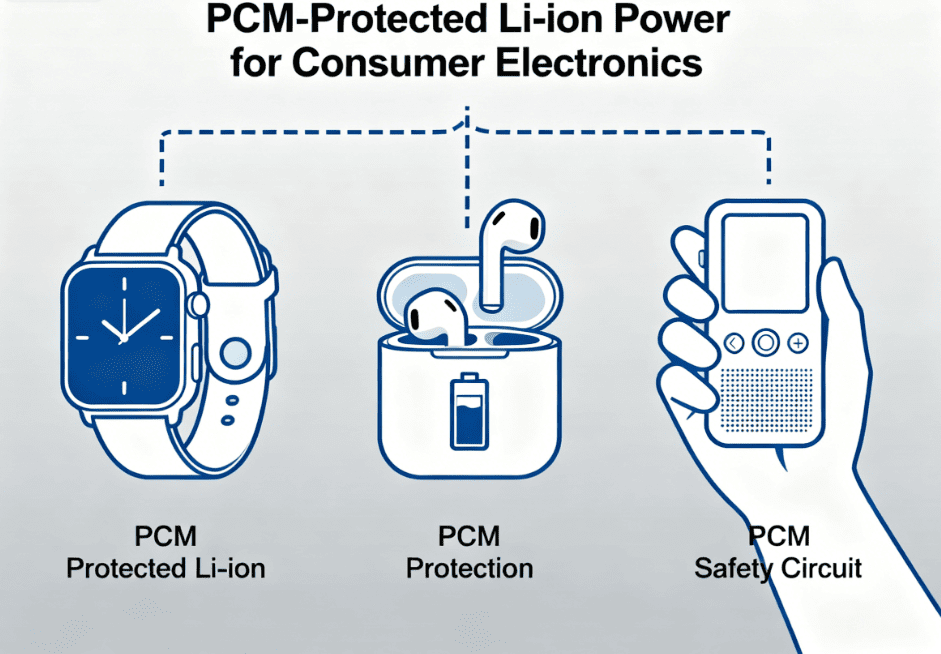

When Should You Use a PCM?

PCM is ideal for low-power, cost-sensitive, or compact devices where:

-

Battery pack is small

-

Current draw is low

-

Cells are arranged in 1S (single-cell) configuration

-

No communication is needed

-

Space constraints are tight

Common PCM Applications

-

TWS earbuds

-

Smartwatches & wearables

-

Bluetooth speakers

-

Electric toothbrushes

-

Handheld consumer electronics

-

Small medical wearables

-

Backup battery modules

PCM is simpler, smaller, and cheaper—but less capable for higher-voltage or high-load systems.

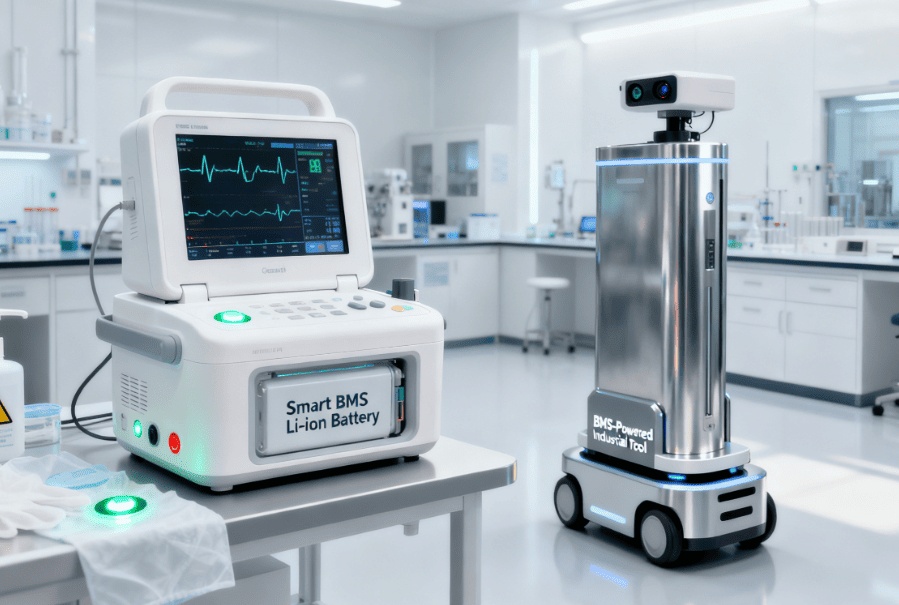

When Should You Use a BMS?

A BMS is necessary when you need safety + intelligence + communication, especially for:

-

Multi-cell battery packs (2S–20S+)

-

High discharge current devices

-

High-value or safety-critical equipment

-

Devices requiring SOC display or data logging

-

Systems that need host communication (CAN/UART)

-

Products requiring long cycle life

Common BMS Applications

-

Medical equipment

-

Hospital-grade breast pumps

-

Electric bicycles & scooters

-

Power tools

-

Drones and UAVs

-

Robots & AGVs

-

Portable medical analyzers

-

Backup power banks

-

Industrial IoT devices

For export-oriented OEMs, a BMS significantly improves reliability and compliance (UL2054, IEC62133-2, KC, PSE, CE).

Technical Breakdown: PCM vs BMS Capabilities

Overcharge & Overdischarge Protection

Both PCM and BMS offer this, but a BMS performs continuous monitoring, not just cut-off.

Table 2: Voltage Protection Thresholds (Typical Values)

| Parameter | PCM | BMS |

|---|---|---|

| Overcharge Voltage | 4.25–4.35V | 4.18–4.25V (configurable) |

| Overdischarge Voltage | 2.3–2.5V | 2.6–3.0V (programmable) |

| Precision | Low | High |

| Response Time | Fast cutoff | Dynamic control |

A BMS offers tighter safety margins and longer cycle life due to precision control.

Charge & Discharge Current Management

PCM uses a MOSFET for cutoff only.

BMS uses:

-

Current sensors

-

Programmed current thresholds

-

Thermal-based current derating

This results in safer operation under varying load conditions.

Temperature Management

PCM:

-

Often includes one NTC

-

Offers “stop charging if too hot” but no detailed data

BMS:

-

Multiple temperature sensors

-

Logs data

-

Provides thermal balancing

-

Communicates with chargers

This is crucial for medical, industrial, and high-current equipment.

Cell Balancing

Balancing keeps multi-cell packs at consistent voltage.

-

PCM: Limited or none

-

BMS: Passive or active balancing

Active balancing improves lifespan by 15–20% in multi-series packs, based on manufacturing test reports.

Data Monitoring & Communication

Only BMS supports:

-

SOC (battery percentage)

-

SOH (battery health)

-

Remaining cycle estimation

-

Fault history

-

Battery ID

-

CAN bus / UART / I²C

Vital for smart devices and IoT systems.

Cost Comparison: PCM vs BMS

Table 3: Typical Cost Ranges (per unit, bulk OEM pricing)

| System Type | Typical Cost | Application |

|---|---|---|

| Basic PCM (1S LiPo) | $0.20 – $0.60 | Small consumer electronics |

| Multi-cell PCM (2S–4S) | $0.60 – $2.00 | Low-cost devices |

| Standard BMS (2S–4S) | $2.00 – $6.00 | IoT, medical, small tools |

| Smart BMS (6S–14S) | $6.00 – $25+ | e-bikes, industrial tools |

| Advanced BMS (15S–20S) | $25 – $60+ | Robotics, UPS, energy equipment |

A BMS costs more—but provides 5–10× more protection and intelligence.

Safety & Compliance: Why BMS Is Often Mandatory

Exporting lithium batteries requires meeting regulations such as:

A BMS helps manufacturers pass critical tests related to:

-

Temperature rise

-

Short-circuit response

-

Overcharge safety

-

Abnormal charging

-

Internal failure simulation

Medical devices, especially Class II, almost always require BMS-level protection.

Which One Should You Choose? (Expert Recommendation Guide)

Choose PCM If:

-

Device is compact and low-power

-

Only a single-cell battery is used

-

Cost and size are priorities

-

No need for data or communication

Choose BMS If:

-

Your device uses multiple cells

-

You need SOC or battery data

-

Product is medical, industrial, or safety-critical

-

You need certification for Europe/USA/Japan

-

Your device has high current draw or long lifespan requirements

Typical Engineering Mistakes When Choosing PCM vs BMS

-

Using PCM in multi-cell or high-current packs

→ Causes imbalance and premature failure. -

Ignoring thermal management

→ Over 40% of field failures come from heat issues that PCM cannot control. -

Designing IoT devices without communication-enabled BMS

→ Results in inaccurate battery level reporting. -

Over-charging cells without SOC monitoring

→ Shortens battery life drastically. -

Failing export certification due to protection limitations

→ Especially in UL2054 and IEC62133 tests.

Practical Examples (Based on Industry Use Cases)

1. Medical Breast Pump Battery

-

Requires BMS due to continuous load and long operation

-

Needs SOC display & precision

-

Demands IEC62133 and UL certification

2. Smart Wearable Device

-

Single-cell LiPo

-

Very low discharge current

-

PCM is sufficient

3. Industrial IoT Sensor

-

Needs long-term stability & data

-

BMS recommended

4. High-Drain Power Tool

-

Requires high-current BMS

-

PCM will fail under load

Frequently Asked Questions (FAQ)

Is a PCM enough for a 2S or 3S battery pack?

Usually not—balancing is required for safety and cycle life.

Can PCM extend battery lifespan?

Minimal effect. A BMS can extend lifespan by up to 20–30% due to balancing and thermal control.

Does a BMS replace a smart charger?

No. A smart charger + BMS is the safest combination.

Is a BMS required for medical devices?

For most devices: Yes.

Conclusion: PCM or BMS — Which Is Right for Your Product?

PCM and BMS both protect lithium batteries, but they serve very different engineering purposes:

-

PCM = Basic safety

-

BMS = Safety + intelligence + communication + optimization

If your device is simple and single-cell, PCM works well.

If your device is high-value, multi-cell, or requires monitoring, BMS is the clear choice.

For OEM applications—especially medical, industrial, and export-grade consumer electronics—a BMS provides longer life, higher stability, and better compliance, making it the recommended option for 2025 and beyond.

-

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More -

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More -

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More -

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More -

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More