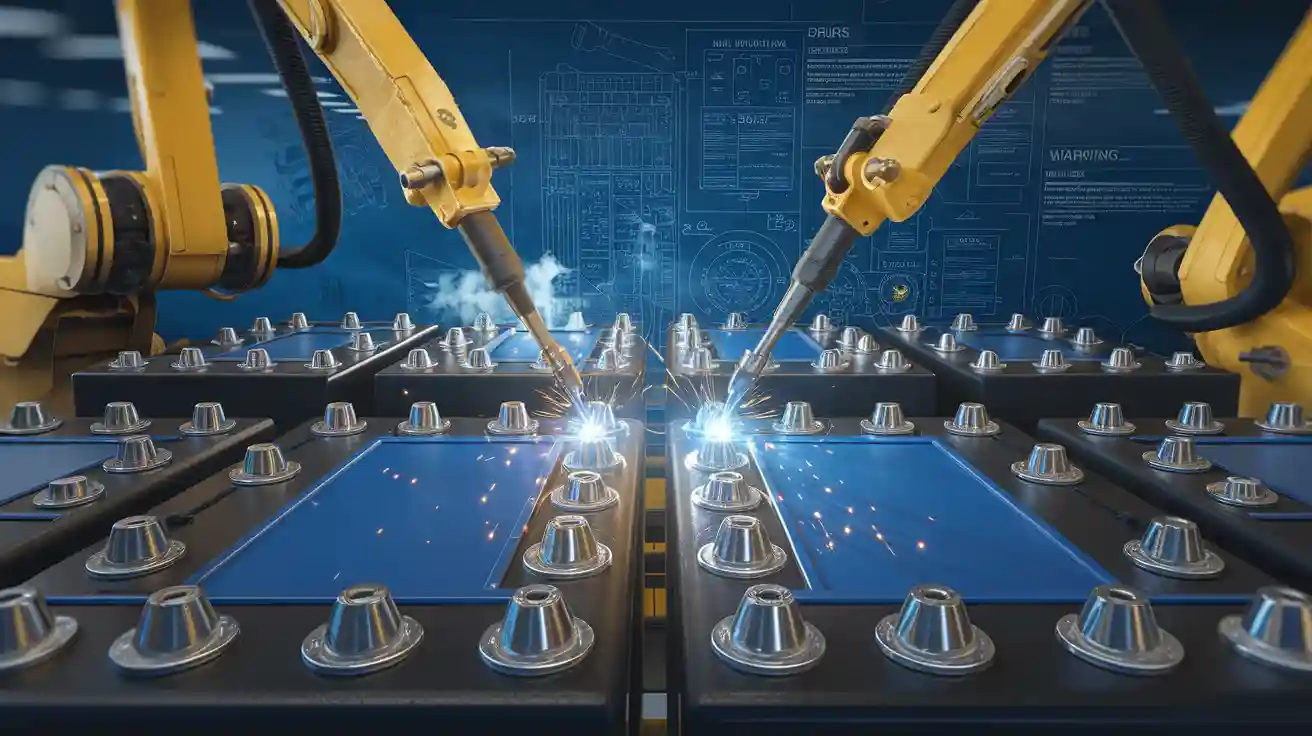

Several major technical difficulties of Power battery welding

You often encounter technical difficulties when welding power batteries. These issues can compromise battery safety and performance. It is essential to control welding settings, match materials, and prevent overheating. Even small mistakes can lead to weak or poor joints. In factories, many workers experience technical difficulties such as improper part placement or materials that do not work well together. The table below lists some common problems you might face:

| Category of Challenges | Description |

|---|---|

| Part Positioning | The size and placement of parts must be right. If not, it can cause errors when putting things together. |

| Material Compatibility | Different materials can form layers that are brittle and resist electricity. |

| Precision of Welding Techniques | You need to prepare electrodes and place parts correctly. Mistakes can result in joints that are not good. |

These technical difficulties can lower quality and make it hard to meet industry regulations.

Key Takeaways

- Watch welding settings closely. Even small changes in energy, force, or time can change how strong the weld is. These changes can also affect battery safety.

- Make sure materials work well together. The right materials stop brittle layers from forming. Brittle layers can block electricity and cause problems.

- Check the welding process as it happens. Sensors can find problems early. This lets workers fix things fast to keep welds good.

- Use good ways to check for problems. Regular checks with different tools can find defects early. This helps stop safety problems before they start.

- Focus on keeping heat under control. Too much heat can hurt batteries. Use cooling and protection to keep temperatures safe.

Welding Parameters

Parameter Control

It is very important to control welding parameters when working with power batteries. Even small changes in energy, force, or timing can change how strong the weld is. If you set the pulse duration or peak current too high or too low, the joints might be weak or the battery could get damaged. You also need to pay attention to how much force you use and when you use it. Using too much force can crush thin materials. Using too little force can make the bond weak.

Here is a table that shows how different parameter controls affect weld quality:

| Parameter | Description | Impact on Weld Quality |

|---|---|---|

| Energy Delivery Control | Pulse duration, peak current, waveform | Determines joint quality and performance |

| Force Application Dynamics | Pre-force timing, force range, follow-up | Impacts material consolidation |

| Material-Specific Factors | Oxide layer, intermetallic formation | Prevents defects and ensures integrity |

You also need to watch the process as it happens. Many factories use sensors to check current, voltage, and force. These sensors help workers find problems early and fix settings before mistakes happen. This careful control helps stop technical difficulties that can hurt battery performance.

Parameter Effects

Welding parameters do more than just affect strength. They also change how safe and reliable the battery is. For example, if you do not control surface roughness or the welding path, you might see more cracks or empty spaces. Different materials, like aluminum or stainless steel, need their own special settings to work best.

The table below shows how some parameters affect weld quality:

| Parameter | Effect on Weld Quality | Notes |

|---|---|---|

| Surface Roughness | Directly impacts weld quality | Different finishes change joint strength |

| Welding Path | Influences joint quality | Varying paths yield different strengths |

| Material Type | Changes weld results | Aluminum and steel need unique settings |

If you do not control these things, you might see more problems like incomplete fusion or spatter. You can lower these risks by testing and changing your process for each battery type. Careful control of parameters helps you meet industry rules and avoid common technical problems in battery welding.

Material Welding

Technical Difficulties in Material Welding

Welding battery materials like nickel, copper, and aluminum is hard. Each metal acts differently, so joining them is tricky.

- Aluminum and copper joints must be strong. If welds are weak, the battery can get hot and unsafe.

- Welding aluminum and copper makes intermetallic compounds. These compounds resist electricity more than the metals. You need to keep these layers thin to stop short circuits or explosions.

- Using different materials in electric vehicle batteries makes welding harder. You have to handle different melting points and how heat moves through each metal.

- Brittle compounds at the weld spot can lower battery power and make it less safe.

- If the joint bends, there can be gaps or leaks.

Welds can also have problems with strength and how the melted area forms. Nickel-plated steel and copper joints in lithium-ion batteries need careful work for good power flow. Resistance spot welding can cause sparks and empty spots, which make the joint weaker.

Aluminum Laser Welding

Aluminum laser welding has its own problems. You have to deal with cracks, shiny surfaces, and gaps. The table below lists common problems and ways to fix them:

| Issue | Description | Solutions |

|---|---|---|

| Crack Sensitivity | Aluminum alloys crack easily when they cool fast | Use heat treatments and slow down welding |

| High Reflectivity | Aluminum bounces laser beams away, so less energy goes in | Focus the laser and pick the right color beam |

| Gap Tolerance | Big gaps need extra care and good settings | Get joints ready and change laser power as needed |

Car and plane makers use special laser welding to make things lighter and safer. You need to pick strong alloys and use the best ways to make them.

Thin Material Issues

Thin materials are even harder to weld. You might see pieces sticking together, weak spots, or bad power flow. The table below shows these problems and what people notice:

| Welding Technique | Challenges Faced | Observations |

|---|---|---|

| Laser Welding | Aluminum rusts and makes intermetallics | Careful work gives strong welds |

| Ultrasonic Welding | Tools wear out and welds can be weak | Welds can break or tear apart |

| Friction Stir Welding | Intermetallics form because of heat and pressure | Where you put the metal changes weld strength |

| Micro-Resistance Welding | Intermetallic size changes with welding current | Metal gets stronger or weaker with current |

| Metal-Inert Gas (MIG) | Needs extra layers to stop intermetallics | Zinc layers help make joints stronger |

Ultrasonic welding can make welds stronger and better at carrying power. Tests help you find the best welding settings. Laser welding, duo-thermal soldering, and high-energy droplet methods also help fix thin material problems.

Heat Management

Overheating Risks

It is important to control heat during power battery welding. If you do not watch the temperature, big problems can happen. Too much heat can hurt the battery and make it unsafe. Here are some main risks you should know:

- Batteries do not last as long if they get too hot. The cells break down faster. This means the battery fails early.

- Hot batteries lose power and do not work well. You may see the battery lose charge often.

- Very high heat can make the battery swell or burst. This can start fires or explosions.

These problems happen in three steps. First, the battery gets hot from too much charging or short circuits. Next, heat builds up and makes gases inside the battery. These gases can melt the separator and cause more short circuits. Last, the gases can catch fire and cause accidents. You need to watch for these signs and act fast to stop damage.

Many companies use cooling methods to stop batteries from getting too hot. Dielectric immersion cooling puts battery cells in a safe liquid. This helps spread heat and keeps the battery working longer. You need a leak-proof design for this method. It can also make the battery heavier.

Sensitive Component Protection

You must keep important parts safe from heat when welding. If you do not, you can damage these parts. Here are some ways to protect them:

- Wear special clothes that stop flames, light, and wear. These clothes help prevent burns and damage.

- Check how well materials protect against heat. Higher thermal protection means better safety and less risk of burns.

- Put overcharging protection circuits in lithium-ion batteries. These circuits keep the battery from getting too hot.

- Use thermal fuses. These melt if the battery gets too hot and stop the current.

- Use special fixturing methods like the unilateral N-2-1 principle. This helps control bending and changes from heat during welding.

You should pick welding ways that make strong joints and little distortion. This keeps the battery safe and working well. Using these methods helps you avoid problems and makes the battery better.

Defect Prevention

Common Defects

When you weld power batteries, you might see some common problems. These problems can make batteries not last as long or be less safe. Here are some problems to look for:

- Open-circuit failure happens if the weld breaks or the tab rips or rusts. The battery might stop working.

- Short-circuit failure can happen if tiny bits of lithium connect the electrodes. This can make the battery short out.

- Latent defects are hidden inside the battery. You may not see them at first. Later, they can cause bigger problems like an inside short.

Other problems you might see are cold welds, burn-through, and bonds that are not even. Each problem has a reason and a way to fix it:

| Defect | Cause | Solution |

|---|---|---|

| Cold welds | Not enough current or short weld time | Use more current or weld longer |

| Burn-through | Too much heat | Weld for less time or use pulse welding |

| Inconsistent bonds | Dirty parts or parts not lined up | Clean parts and line up the electrodes |

You should find these problems early. This helps you stop bigger issues later.

Prevention Strategies

There are good ways to stop welding problems when making power batteries. Many factories use special checks to find problems before they get worse:

| Inspection Technique | Description | Benefits |

|---|---|---|

| Laser Thermography | Finds hidden weld problems in batteries. | Checks in real time and does not touch the battery. |

| Computer Vision Inspection | Uses cameras to look at welds. | Gives clear pictures but might miss very small problems. |

| X-ray Microscopy | Shows tiny things and problems inside the weld. | Lets you see all of the weld quality. |

| Eddy Current Testing | Looks for changes in how electricity moves to find problems. | Works well for problems on or under the surface. |

| Ultrasonic Inspection | Uses sound waves to find cracks or gaps. | Finds problems without hurting the battery. |

| Destructive Inspection | Takes batteries apart to check welds. | Shows how strong the weld is when stressed. |

| Thermal Response Magnification | Uses heat and lasers to make small problems easier to see. | Helps you find tiny problems better. |

You can also do these things to stop problems:

- Change welding settings for each job and material.

- Watch the process in real time to catch mistakes fast.

- Make clear rules and teach workers what to do.

- Test batteries often to make sure they are safe.

- Check machines often to keep them working well.

- Use smart machines and robots to make fewer mistakes.

- Teach your team to find and fix problems quickly.

If you use these ways, you can stop many problems and make batteries that last longer and are safer.

Quality Assurance

Inspection Methods

You need good ways to check every battery weld. Factories use many methods to make sure welds are strong.

- Laser welding systems can make many tight welds. These systems check weld depth as you work. This helps you find problems fast.

- Visual inspection lets you see if there are problems on the surface. People can do this, but robots with cameras do it faster. Robots also find more mistakes than people.

- Validation engineers use different tests to check battery cells. Each test looks for something special. This gives you a full idea of how good the weld is.

Special tools help you find hidden problems. High-throughput CT scanning shows the inside of the battery. Acoustic inspection uses sound to find cracks or gaps you cannot see. X-ray methods help you find problems inside the weld. You must be careful and follow safety rules when using X-rays.

Here is a table that shows some ways to check welds:

| Inspection Method | Advantages | Limitations |

|---|---|---|

| Visual Inspection | Easy, quick, and not costly | Only finds problems you can see |

| X-ray Inspection | Looks inside the weld for hidden issues | Needs safety steps and can cost a lot |

| Ultrasonic Inspection | Finds cracks and gaps deep in the weld | Needs skilled workers and may miss surface problems |

You can use more than one way to check for problems. This helps you find all types of defects. It also helps you stop issues that could make batteries unsafe.

Standards

You must follow strict rules to keep batteries safe and strong. These rules tell you how to test and check every weld.

- Physical property tests, like tensile and shear tests, show how strong the weld is when pulled or pushed.

- Resistance measurement lets you see if the weld matches standard numbers. If resistance is too high, the weld may be weak.

- Battery charge and discharge cycle tests show if the weld changes how long the battery lasts or works.

Tip: Always use more than one test. This helps you find problems before the battery leaves the factory.

Good quality control is very important. You need to use many ways to check for cold welding and other problems. When you follow these rules, your batteries last longer and work better. You also meet industry rules and keep people safe.

Manufacturing Challenges

Scale-Up Issues

Making more power batteries at once brings new problems. Each battery module has lots of small welds. Every weld must be checked to keep the battery safe. Factories use special clamps to hold parts steady. These clamps help the laser welding work better. Watching the welds as they happen helps find problems fast. Even with machines, people still need to check the welds. Sometimes, workers have to look at every module. This can make things go slower. Welding machines must stay clean. If dirt or dust gets in, it can cause mistakes and stop the work.

- Every weld must be high quality.

- Special clamps help make better welds.

- Watching welds live finds problems fast.

- People still need to check for safety.

- Clean machines help things run smoothly.

Safety Mechanisms

Strong safety systems are needed when making many batteries. Risk analysis helps find and fix dangers in the process. You must follow world safety rules to keep workers and products safe. Using new technology like laser welding makes things safer and faster.

- Risk analysis helps find and lower dangers.

- Following safety rules keeps everyone safe.

- New welding tools lower risks and make better welds.

Tip: Always check your safety systems before you start. This keeps your team and products safe.

Digital Integration

Digital tools change how batteries are welded. Companies like ATS Industrial Automation show how to go from lab tests to big production. They work with experts to make welding steps better. This teamwork gives stronger welds and saves time. With over 110 battery lines built, they show digital tools really help.

You can connect laser welding machines with robots and AI. These systems watch welds as they happen and change settings if needed. Machine learning helps the process get better over time. It learns from new materials and changes in the factory.

- Robots and AI help keep welds strong.

- Watching welds live lets you fix problems fast.

- Machine learning helps you get better as you work.

You can have problems when welding power batteries. These problems can make batteries less safe and not work as well. You can fix many problems with direct press ultrasonic welding. This method gives you more control and holds big cables tight. Using better tools with new coatings and knurling helps tools last longer and not slip. Higher power management lets you handle more power for bigger wires. The table below shows some good ways to help:

| Best Practice | Description |

|---|---|

| Direct Press Ultrasonic Welding | Gives more control and holds big cables tight. |

| Improved Tooling | New coatings and knurling help tools last longer and not slip. |

| Higher Power Management | Handles more power for bigger wires. |

You should also use machines to check welds and test them without breaking anything. Watching the process as it happens helps you find problems fast and keep welds strong. New ideas and following strict rules make batteries safer and work better.

-

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More -

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More -

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More -

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More -

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More