The Evolution of Lithium Battery Technology: From Lab Research to Mass Production

You witness the rapid transformation of the History Of Lithium Battery as researchers and industry leaders shape modern life. The journey starts with breakthroughs in the 1970s and continues through major milestones:

- 1970: John B. Goodenough develops new anode materials.

- 1991: Sony introduces the first rechargeable lithium-ion battery.

- 2008: Tesla launches the Roadster, revolutionizing electric vehicles.

| Decade | Key Developments in Lithium Battery Market |

|---|---|

| 1970s | Commercial primary lithium batteries debut in consumer markets. |

| 2010s | Portable electronics and IoT drive global demand. |

You gain insight into how innovation and market needs drive each leap forward.

Key Takeaways

- Lithium battery technology began in the 1970s with key breakthroughs that paved the way for rechargeable batteries.

- Sony's launch of the first commercial lithium-ion battery in 1991 revolutionized portable electronics, making devices lighter and longer-lasting.

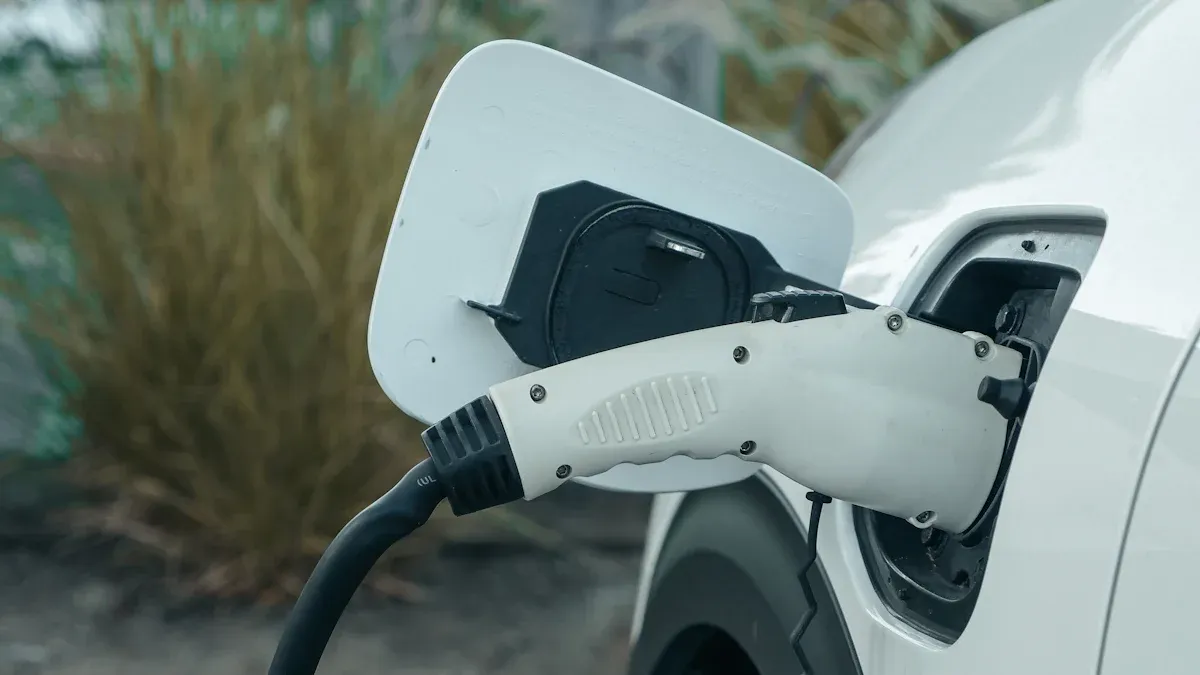

- The electric vehicle market has rapidly adopted lithium-ion batteries, leading to cleaner and more efficient transportation options.

- Partnerships and licensing agreements among companies have accelerated the development and commercialization of battery technologies.

- Sustainability efforts are crucial as the demand for lithium batteries grows; recycling and eco-friendly practices are becoming more important.

History of Lithium Battery

Early Research in the 1970s

You can trace the history of lithium battery back to the 1970s, a decade filled with curiosity and experimentation. Scientists around the world started to explore how lithium could power the future.

- In 1965, Walter Rüdorff noticed that titanium disulfide (TiS₂) could hold lithium ions.

- By 1970, M.S. Whittingham used TiS₂ as a cathode, which marked the beginning of rechargeable lithium battery development.

- In 1973, Whittingham applied this discovery to create a working battery.

- Exxon, an oil company, produced the first commercial lithium battery in 1976. This battery used lithium metal and titanium disulfide.

- In 1979, John Goodenough, Rachid Yazami, and Koichi Mizushima made important advancements. Goodenough’s work on lithium cobalt oxide (LiCoO₂) improved battery performance and set the stage for future progress.

The first lithium batteries faced many technical challenges. Early versions, developed by Exxon during the 1970s oil crisis, were not rechargeable. They used lithium compounds that created toxic by-products in the electrolyte. These batteries powered the first digital watches, but they were risky. Gases from the electrolyte could build up and cause the battery to burst into flames when exposed to air.

During this period, researchers also explored graphite’s ability to store lithium ions. Sanyo’s team and Jeff Dahn worked on practical applications, which would later become important for lithium-ion batteries. The history of lithium battery in the 1970s shows how scientists and companies worked together to solve problems and push technology forward.

Breakthroughs in the 1980s

You see the pace of advancements increase in the 1980s. John B. Goodenough and his team made a major breakthrough in 1980. They developed lithium cobalt oxide (LiCoO₂) as a cathode. This new material increased battery voltage from about 2.4 volts to nearly 4 volts. It also removed the need for unstable pure lithium metal, making batteries safer and more reliable.

- Goodenough’s discovery doubled the energy potential of lithium batteries.

- He patented this technology in 1981, but it took almost a decade before it reached consumers.

- The foundation for lithium-ion batteries was now in place, thanks to these advancements.

Key companies and research teams played a big role in the history of lithium battery during this time. Goodenough’s group at the Atomic Energy Research Establishment (AERE) led the scientific progress. Sony and Asahi Kasei later worked together to bring lithium-ion batteries to the market. Yoshio Nishi led the Japanese team that made commercial production possible.

The divide between research and commercial use became clear in the 1980s. Scientists like Goodenough, Whittingham, and Yoshino made important discoveries. Sony’s business strategy turned these discoveries into products that changed the world. The history of lithium battery in this decade highlights how teamwork between researchers and companies led to the technology you use today.

The advancements of the 1980s set the stage for the first commercial lithium-ion batteries. These batteries would soon power laptops, cell phones, and many other devices. You can see how the history of lithium battery moved from the lab to everyday life, shaping the modern world.

Lithium-Ion Batteries Milestones

1991 Sony Commercial Launch

You step into 1991, a year that changed battery technology forever. Sony introduced the world’s first commercial lithium-ion batteries. This launch marked a turning point in the commercialization of rechargeable batteries. You could now use devices that lasted longer, charged faster, and weighed less.

Here is a quick look at what made Sony’s lithium-ion batteries stand out:

| Feature | Description |

|---|---|

| High Energy Density | Provided more power in a smaller, lighter package. |

| Low Self-Discharge Rates | Held charge longer when not in use, making devices more reliable. |

| No Memory Effect | Allowed you to recharge at any time without reducing battery life. |

| Longer Cycle Life | Lasted through hundreds or even thousands of charge cycles. |

Sony’s innovation did not just improve batteries. It sparked advancements in fast charging, thermal stability, and recycling. You saw the beginning of a new era for portable electronics and electric vehicles.

The 1991 launch by Sony set a new standard for safety and longevity. You could now trust your devices to last longer and perform better.

Adoption in Consumer Electronics

After Sony’s launch, you watched lithium-ion batteries quickly become the top choice for consumer electronics. Manufacturers started using them in camcorders, portable audio players, and mobile phones. The high energy density and long cycle life made these batteries perfect for your everyday gadgets.

- You noticed smartphones and laptops became lighter and more powerful.

- The battery industry shifted focus to lithium-ion batteries as a key selling point.

- The technology expanded into electric vehicles, making them more efficient and reliable.

| Impact of Lithium-Ion Batteries | Description |

|---|---|

| First Commercialization | Sony’s 1991 launch brought lithium-ion batteries to the market. |

| Safety and Longevity | Devices became safer and lasted longer. |

| Expansion of Applications | Batteries powered more types of devices, from phones to laptops. |

| Industry Adoption | Companies promoted lithium-ion batteries as a major feature. |

You benefit from these advancements every day. Lithium-ion batteries now power the fastest-growing sectors in technology, from smart devices to electric cars. The commercialization of this battery technology continues to shape your world.

Commercialization Stages

Initial Development Phase

You enter the initial development phase of lithium battery commercialization in the 1970s and 1980s. During this time, you see researchers and companies face many technical and commercial challenges. The pathway from laboratory discovery to commercial applications is never simple. You notice that the complexity of battery technology makes it difficult to scale new battery technology for mass production.

- You need significant capital investment to move from small-scale experiments to full-scale manufacturing.

- You must develop new manufacturing capabilities alongside the technology itself.

- Safety assessments for new battery chemistries, especially solid-state batteries, are still evolving.

- The absence of established safety standards for these new battery types complicates the commercialization pathway.

You realize that these hurdles slow down the transition from research to market. Early rechargeable lithium batteries often struggle with safety and reliability. Companies like Exxon and Sanyo experiment with new battery technology, but you see that cost and scalability remain major obstacles. The pathway to successful commercialization requires not only scientific breakthroughs but also the ability to produce batteries safely and at scale.

Market Expansion in the 1990s

You watch the market for lithium-ion batteries expand rapidly in the early 1990s. Sony’s 1991 launch of the first commercial lithium-ion battery marks a turning point in the commercialization pathway. You see Motorola use lithium-ion batteries in mobile phones by 1994, which signals the start of a new era for portable electronics.

- In the 1990s, you notice lithium-ion batteries appear in mobile phones and laptops. This shift marks a significant change in battery technology.

- The transition to lithium-ion batteries happens because these batteries require lower voltage, moving from 5.5V to 3V. This makes them more efficient than older nickel-cadmium batteries.

- Lithium-ion batteries are thinner, lighter, and last longer than previous battery types.

- Manufacturers can produce them in many shapes and sizes, which allows for new designs in mobile phones and other devices.

You see the market respond quickly to these advantages. The scalability of lithium-ion batteries improves as companies invest in better manufacturing processes. The commercialization pathway becomes clearer as demand for portable electronics grows. You notice that battery performance becomes a key selling point for new products. The market for rechargeable lithium batteries expands beyond consumer electronics, reaching into early electric vehicles and other energy storage solutions.

Widespread Adoption

You witness widespread adoption of lithium-ion batteries from the late 1990s onward. The commercialization pathway now stretches across many industries. The market for lithium-ion batteries grows at a rapid pace. You see the global market projected to rise from $117.8 billion in 2024 to $221.7 billion by 2029, with a compound annual growth rate of 13.5%. This growth shows how important lithium-ion batteries have become for modern technology.

- The material handling industry shifts from internal combustion forklifts to electric-powered forklifts. Now, 70% of the market uses electric forklifts, showing a strong move toward lithium battery usage.

- The rapid adoption of lithium-ion technology in electric-powered forklifts highlights a major trend in the industry.

- You see lithium-ion batteries power not only consumer electronics but also electric vehicles, grid storage, and industrial equipment.

You recognize that the scalability of new battery technology drives this growth. Companies focus on improving battery performance, safety, and cost. The commercialization pathway now includes recycling and sustainability efforts, which help support the growing demand for batteries. You see rechargeable lithium batteries become the backbone of modern energy storage solutions and transportation. The pathway from lab discovery to global market dominance is now clear, with lithium-ion batteries leading the way in many applications.

Commercialization Strategies

Licensing and Partnerships

You see that successful commercialization strategies often begin with strong licensing agreements and industry partnerships. These agreements allow companies to share technology, reduce risks, and speed up the spread of lithium-ion batteries. When you look at the history of battery technology, you notice that many leading companies have used licensing to gain access to new innovations and markets.

| Companies Involved | Licensing Agreement Details |

|---|---|

| QuantumScape and PowerCo | Expanded collaboration to accelerate solid-state battery technology, with PowerCo providing up to $131 million in payments for milestones. |

| Dragonfly Energy and Stryten | $30 million licensing agreement for Battle Born Batteries brand. |

| Tesla and Panasonic | Collaboration for high-density lithium-ion battery cells, with Tesla receiving around 2 billion cells between 2013 and 2017. |

You can see how these partnerships help companies scale up quickly and bring new products to market. For example, Tesla and Panasonic worked together to produce high-density lithium-ion batteries for electric vehicles. QuantumScape and PowerCo joined forces to push solid-state battery technology forward. These commercialization strategies help companies stay ahead in a fast-changing industry.

Industry partnerships also play a key role in the global spread of lithium-ion batteries. You find that companies often work together to improve recycling, stabilize supply chains, and lower emissions.

| Partnership | Contribution | Outcome |

|---|---|---|

| VinES and KION | Recover 95% materials with low emissions | Increased capacity 10x |

| Volkswagen and Redwood Materials | Stabilize supply via vertical integration | Lower CO2 emissions |

| GM and Li-Cycle | Stabilize supply via vertical integration | Efficient supply chains |

| BASF and CATL | Build recycling networks | Enhanced recovery technologies |

Tip: When companies form alliances, they can adapt faster to market changes and reduce risks from supply shortages.

You notice that countries and companies benefit from diversifying their technology partnerships. By joining multilateral alliances, you can increase your ability to adapt and compete in the global market.

Scaling Production

You watch as scaling production becomes a central part of commercialization strategies for lithium-ion batteries. Companies must move from small pilot lines to massive factories. This step requires new investments, advanced automation, and strict quality control. You see Sony and Asahi Kasei lead the way in the 1990s by building large-scale plants for battery production.

To meet growing demand, you find that companies invest in gigafactories and new manufacturing techniques. These efforts help lower costs and improve battery performance. You also see a focus on recycling and sustainability as part of modern commercialization strategies. By scaling production, you help make lithium-ion batteries more affordable and available for everything from smartphones to electric vehicles.

Electric Vehicles Lithium Battery

Entry into Automotive Sector

You see the electrification of vehicles accelerate as automotive companies invest in electric vehicles lithium battery technology. Early pioneers like CATL and General Motors (GM) lead the way. CATL partners with Tesla and BMW, supplying advanced batteries for their electric vehicles. GM collaborates with LG Energy Solution to develop lithium manganese-rich battery cells for future trucks and SUVs. CATL also expands production in Europe and North America, focusing on battery recycling to support sustainable growth. GM pushes for breakthroughs in battery technology, aiming to improve performance and reliability.

Automakers recognize the advantages of lithium-ion batteries. High energy density allows vehicles to travel longer distances on a single charge. The cost of lithium-ion batteries drops below US$100/kWh, making electric vehicles more affordable for you. Over the past 30 years, battery costs fall by 99%, while energy density increases fivefold. Every time deployment doubles, battery costs decrease by 19%. These improvements encourage more companies to enter the electric vehicle market.

Tip: Lower battery costs and higher energy density make electric vehicles lithium battery systems attractive for both manufacturers and consumers.

Impact on Electric Vehicles

You notice lithium-ion batteries become the most widely used energy source for electric vehicles. Their structural advantages drive interest and adoption, especially since the 2010s. The electric vehicle market grows rapidly, with sales of battery EVs and plug-in hybrid electric vehicles rising each year. Even during the COVID-19 pandemic, EV sales continue to increase, especially in China.

By 2018, global lithium-ion battery sales reach 160 GWh, with 44% used in electric vehicles and e-buses. This growth highlights the critical role of electric vehicles lithium battery technology in cleaner transportation. In 2019, electric car sales hit 2.1 million, making up 2.6% of global car sales. Government incentives and stricter emission regulations encourage you to choose electric vehicles over traditional models.

- Lithium prices decrease, reducing the cost of cells to 7.5% of an EV’s price as of August 2024.

- High energy density lets you drive farther without increasing battery size.

- The electric vehicle market expands as battery technology improves and costs fall.

You benefit from these advancements every time you drive an electric vehicle powered by lithium batteries. The electric vehicles lithium battery revolution shapes the future of transportation, making vehicles cleaner, more efficient, and accessible.

Current Trends and Future Outlook

Innovations in Battery Chemistry

You see rapid advancements in lithium battery technology as researchers and companies push for next-generation lithium battery technologies. New chemistries and materials promise better performance, safety, and sustainability. Here are some of the most exciting developments:

- Lithium-oxygen batteries use hemoglobin proteins in carbon nanotubes, offering high-capacity energy storage.

- Solid-state batteries provide higher energy density, faster charging, and improved safety compared to traditional designs.

- Lithium iron phosphate cathodes now power more electric vehicles, thanks to their improved performance and longer lifespan.

- Silicon anodes boost energy density and enable faster charging, making devices last longer between charges.

- High-loading potassium-selenium batteries combine metals to increase storage capacity.

- Sustainable battery technologies recover lithium and graphite from used batteries, reducing waste and supporting sustainable alternatives.

You notice that leading companies and research institutions drive these advancements. The table below highlights some of the top innovators and their recent patents or projects:

| Company/Institution | Innovation/Patent Description |

|---|---|

| SiLi-ion | Patent on silicon-based anodes for longer battery life |

| CustomCells | Silicon anode technology innovations |

| CATL | Silicon-carbon composite for faster charging |

| COSMX | Silicon-carbon particles for better stability |

| LG Energy Solution | Lithium battery advancements |

| ATL | Lithium battery technology innovations |

| General Motors | Research in lithium battery technologies |

| BYD | Advancements in lithium battery technology |

| Toyota | Innovations in lithium battery technology |

These battery technology advancements help you enjoy longer-lasting devices and more reliable electric vehicles. You benefit from safer, more efficient batteries as commercialization continues to accelerate.

Sustainability and Recycling

You face growing concerns about sustainability as battery use increases worldwide. The production and disposal of lithium batteries present several challenges:

- High carbon emissions during production mean lithium-ion batteries can create more CO2 than gasoline-powered cars.

- Mining for battery materials causes environmental contamination, with about 40% of the climate impact coming from mineral extraction and processing.

- Hazardous waste remains a problem, as 98.3% of lithium-ion batteries end up in landfills, risking soil and groundwater pollution.

- Only about 5% of lithium batteries are recycled globally, while 99% of lead car batteries in the U.S. get recycled.

- Landfills report fires caused by discarded lithium-ion batteries, with one site in the Pacific Northwest experiencing 124 fires over three years.

You see hope in new recycling methods and regulations. Recent advancements allow recovery of highly pure lithium carbonate and achieve leaching efficiencies of 97% for lithium and 98% for cobalt. Global recycling rates for lithium-ion batteries reached 58% in 2019, showing real progress. In China, electric vehicle manufacturers must set up recycling channels, and hundreds of companies now participate in a national traceability platform. By 2025, recycled lithium could supply 9% of the total market, with recycled cobalt meeting nearly 20% of demand.

You play a role in supporting sustainable alternatives by choosing products from companies that invest in recycling and eco-friendly practices. As battery technology continues to evolve, you can expect even more sustainable alternatives and solutions in the near future.

You have seen how lithium battery technology moved from early research to global commercialization, shaping the world around you. The impact on electronics and electric vehicles stands out in recent years.

| Metric | Value |

|---|---|

| Global battery market by 2030 | $423.9 billion |

| EV sales in H1 2024 | 7 million (25% increase) |

| Estimated EVs by end of 2025 | 85 million |

You can expect even greater advances as solid-state batteries and new materials drive the next wave of innovation. The future of battery technology promises safer, longer-lasting, and more sustainable solutions for your everyday life.

FAQ

What makes battery technology important for modern devices?

You rely on battery technology for smartphones, laptops, and electric vehicles. This technology stores energy efficiently and powers your devices for hours. Researchers continue to improve battery technology to make your daily life easier and more reliable.

How do solid-state batteries differ from traditional lithium-ion batteries?

You find that solid-state batteries use a solid electrolyte instead of a liquid one. This change increases safety and energy density. Solid-state batteries also last longer and charge faster. Many experts believe solid-state batteries will transform battery technology in the future.

Why do experts consider solid-state batteries safer?

You see that solid-state batteries do not use flammable liquid electrolytes. This design reduces the risk of fires and leaks. Solid-state batteries also resist overheating. Safety improvements make solid-state batteries a top choice for next-generation battery technology.

What challenges slow down the adoption of solid-state batteries?

You notice that solid-state batteries face manufacturing and cost challenges. Producing solid-state batteries at scale requires new equipment and materials. Battery technology companies invest in research to solve these problems. You can expect progress as battery technology advances.

How will solid-state batteries impact electric vehicles and energy storage?

You will benefit from solid-state batteries in electric vehicles and grid storage. These batteries offer higher energy density and faster charging. Battery technology experts predict longer driving ranges and safer vehicles. Solid-state batteries will also support renewable energy systems.

-

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More -

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More -

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More -

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More -

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More