Battery Pack for Plug-In Light: Complete Technical & OEM Guide

In commercial and industrial lighting systems, a reliable battery pack for plug-in light plays a critical role in ensuring stable power delivery, operational safety, and long-term system performance. From our experience working with OEMs, engineers, and procurement teams across Europe and North America, lighting battery packs are no longer optional accessories — they are core system components.

- 1. What Is a Battery Pack for Plug-In Light?

- 2. Why Plug-In Lighting Needs Dedicated Battery Packs

- 3. Common Commercial & Industrial Applications

- 4. Battery Chemistries Used in Plug-In Light Systems

- 5. Voltage, Capacity & Power Design Considerations

- 6. Safety Standards & Certifications (EU & US)

- 7. OEM & Custom Battery Pack Development Process

- 8. Performance Data & Comparison Table

- 9. How to Choose the Right Battery Pack Supplier

- 10. Cost Structure & Procurement Factors

- 11. Future Trends in Plug-In Light Battery Solutions

- 12. FAQ

1. What Is a Battery Pack for Plug-In Light?

A battery pack for plug-in light is a rechargeable power module designed to supply stable electrical energy to lighting devices that normally operate via wall power or external adapters.

In commercial and industrial environments, these battery packs are widely used to:

-

Provide backup power during outages

-

Enable portable or semi-fixed lighting systems

-

Improve energy efficiency and system reliability

-

Meet safety and emergency lighting requirements

From an engineering perspective, a plug-in light battery pack is not just a battery, but an integrated system including:

-

Lithium battery cells

-

Battery Management System (BMS)

-

Protection circuits

-

Output connectors and wiring harness

-

Mechanical housing compatible with lighting equipment

2. Why Plug-In Lighting Needs Dedicated Battery Packs

Unlike consumer flashlights, plug-in lighting systems operate under continuous load conditions and stricter safety requirements.

From our project experience, manufacturers choose dedicated battery packs because they offer:

Engineering Advantages

-

Stable voltage output for LED drivers

-

Predictable runtime under constant load

-

Reduced system downtime

Commercial Benefits

-

Compliance with EU & US regulations

-

Longer lifecycle compared to generic power banks

-

Easier OEM integration

Operational Reliability

-

Controlled charge/discharge profiles

-

Thermal protection for enclosed lighting fixtures

-

Consistent brightness output

3. Common Commercial & Industrial Applications

Battery packs for plug-in lights are widely deployed across multiple B2B sectors:

Commercial Lighting

|

Industrial & Utility

|

Medical & Professional Environments

|

Smart & IoT Lighting

|

4. Battery Chemistries Used in Plug-In Light Systems

Choosing the right battery chemistry is critical for performance and compliance.

Lithium-Ion (Li-ion)

|

Lithium Polymer (LiPo)

|

LiFePO₄ (Lithium Iron Phosphate)

|

5. Voltage, Capacity & Power Design Considerations

For plug-in light battery packs, design starts with load requirements.

Key Parameters

-

Nominal Voltage (V)

-

Capacity (Ah / mAh)

-

Power Output (W)

-

Peak Current

Typical Configurations

| Application | Voltage | Capacity Range |

|---|---|---|

| Desk & Display Lighting | 7.4V | 2000–5000mAh |

| Emergency Lighting | 12V | 4000–10000mAh |

| Industrial Lamps | 24V | 6000–20000mAh |

Runtime is calculated based on actual system load, not rated LED wattage alone.

6. Safety Standards & Certifications (EU & US)

For OEM buyers in Europe and North America, compliance is non-negotiable.

Common Required Certifications

-

UN38.3 – Transportation safety

-

IEC 62133 – Battery safety

-

UL 2054 / UL 1642 – US market

-

CE / RoHS / REACH – EU market

Battery packs for plug-in lights must also meet thermal and enclosure safety standards, especially for fixed installations.

7. OEM & Custom Battery Pack Development Process

We typically follow a structured OEM workflow:

-

Application requirement analysis

-

Electrical design & cell selection

-

BMS customization

-

Mechanical housing design

-

Safety & compliance validation

-

Pilot production & testing

-

Mass production & QC

This process ensures compatibility with existing plug-in light systems while optimizing cost and reliability.

8. Performance Data & Comparison Table

| Parameter | Standard Pack | OEM Custom Pack |

|---|---|---|

| Cycle Life | 500–800 cycles | 800–2000 cycles |

| Efficiency | ~88% | 92–95% |

| Protection | Basic | Advanced BMS |

Data based on industry averages from IEC and UL testing benchmarks.

9. How to Choose the Right Battery Pack Supplier

For procurement and engineering teams, key evaluation criteria include:

-

Proven OEM experience

-

In-house BMS design capability

-

Compliance documentation support

-

Stable supply chain

-

Engineering communication efficiency

A reliable supplier should act as a technical partner, not just a component vendor.

10. Cost Structure & Procurement Factors

Battery pack cost depends on:

-

Cell chemistry & brand

-

BMS complexity

-

Certification scope

-

Order volume

For B2B buyers, total lifecycle cost is often more important than unit price.

11. Future Trends in Plug-In Light Battery Solutions

-

Market trends show increasing demand for:

-

Smart BMS with communication interfaces

-

Higher energy density cells

-

Modular battery systems

-

Sustainable and recyclable materials

-

These trends align with EU energy efficiency policies and US safety standards.

12. FAQ

Q1: Can a battery pack replace AC power for plug-in lights?

In many applications, yes—especially for backup or portable lighting systems.

Q2: What is the typical lifespan of a plug-in light battery pack?

Depending on chemistry and usage, 2–5 years is common.

Q3: Can battery packs be customized for existing lighting designs?

Yes. OEM customization is standard for voltage, size, connectors, and protection logic.

Looking for a reliable OEM battery pack supplier?

Explore our custom lithium battery pack solutions or learn more about our lithium polymer battery capabilities.

-

May.2026.02.127.4V LiPo Battery — A Practical Guide (2S Li-Po / 7.4V)Learn More

May.2026.02.127.4V LiPo Battery — A Practical Guide (2S Li-Po / 7.4V)Learn More -

May.2026.02.10Lithium Polymer Battery Supply Chain Explained: From Raw Materials to Custom Power SolutionsLearn More

May.2026.02.10Lithium Polymer Battery Supply Chain Explained: From Raw Materials to Custom Power SolutionsLearn More -

May.2026.02.097.2V Li-ion Battery Pack – A Complete Technical & Application GuideLearn More

May.2026.02.097.2V Li-ion Battery Pack – A Complete Technical & Application GuideLearn More -

May.2026.02.06Lithium-Ion Battery Energy Density: How Much Energy Can We Really Store?Learn More

May.2026.02.06Lithium-Ion Battery Energy Density: How Much Energy Can We Really Store?Learn More -

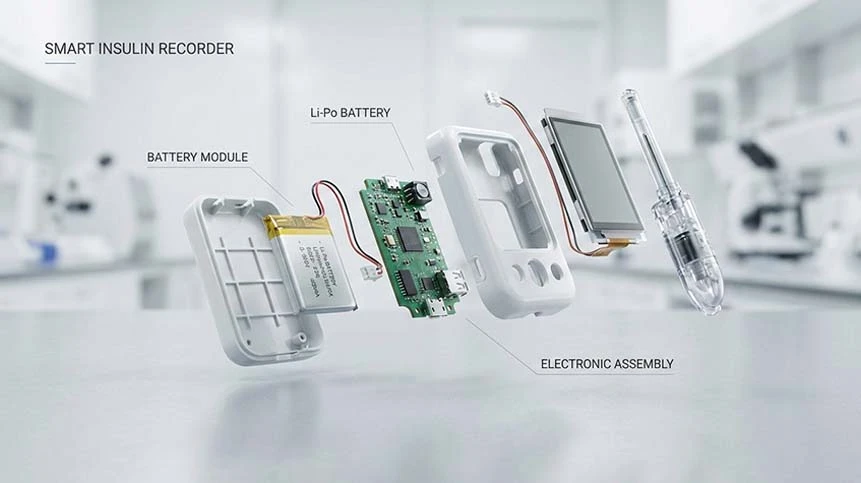

May.2026.02.05Smart Insulin Recorder Battery: Powering Accurate Diabetes Management DevicesLearn More

May.2026.02.05Smart Insulin Recorder Battery: Powering Accurate Diabetes Management DevicesLearn More