Lithium Polymer Battery Supply Chain Explained: From Raw Materials to Custom Power Solutions

Introduction: Why OEMs Need to Understand the Lithium Polymer Battery Supply Chain

Lithium polymer batteries have become a foundational power source for compact, portable, and safety-critical electronic devices. Unlike standardized cylindrical lithium-ion batteries, lithium polymer batteries are highly application-driven. Their thin profile, flexible shape, and customizable design make them ideal for medical devices, wearables, IoT products, and advanced consumer electronics.

However, these advantages also introduce complexity. Battery performance, safety, reliability, and cost are not determined by a single factor, but by the entire lithium polymer battery supply chain. From upstream material selection to midstream manufacturing processes and downstream application requirements, each stage plays a critical role.

For OEMs, engineers, and procurement teams, understanding this supply chain is not academic—it directly affects product success, regulatory approval, and long-term supply stability. This guide provides a detailed, engineering-focused explanation of the lithium polymer battery supply chain, with real-world design considerations and application examples.

1. Overview of Lithium Polymer Battery Technology

Lithium polymer batteries are a form of lithium-ion battery that uses a laminated pouch structure instead of rigid metal casings. While the electrochemical reactions are similar to other lithium-ion systems, the packaging and internal design allow greater flexibility in form factor and thickness.

Key Characteristics of Lithium Polymer Batteries

-

Ultra-thin and lightweight construction

-

Flexible dimensions and custom shapes

-

High gravimetric and volumetric energy density

-

Stable discharge characteristics

-

Broad applicability across consumer, medical, and industrial devices

Because lithium polymer batteries are often designed around specific products, supply chain integration becomes far more important than in standardized battery formats.

2. Upstream Supply Chain: Raw Materials and Key Components

The upstream segment defines the theoretical performance limits of lithium polymer batteries. Decisions made at this stage influence energy density, thermal behavior, aging characteristics, and safety margins.

2.1 Cathode Materials: Balancing Energy Density and Stability

Lithium Cobalt Oxide (LCO)

LCO remains the most common cathode material for lithium polymer batteries used in compact electronics.

Advantages:

-

High energy density

-

Stable voltage plateau

-

Mature manufacturing ecosystem

Limitations:

-

Higher cost due to cobalt content

-

Requires strict protection design

Typical applications: ultra-thin batteries, wearables, consumer electronics.

Nickel Cobalt Manganese (NCM)

NCM materials offer a balance between performance and safety. Adjusting the Ni/Co/Mn ratio allows manufacturers to tune energy density and cycle life.

Advantages:

-

Improved thermal stability

-

Longer cycle life than LCO

-

Suitable for higher-capacity designs

Typical applications: medical devices, industrial electronics, premium consumer products.

Engineering Insight

For OEM projects, cathode selection is often driven by space constraints and cycle life requirements, not just energy density. Over-optimizing for capacity can introduce thermal and aging risks at the pack level.

2.2 Anode Materials: Managing Capacity and Expansion

Most lithium polymer batteries use graphite-based anodes.

-

Artificial graphite: consistent particle size, stable performance

-

Natural graphite: cost-efficient, slightly higher variability

Silicon-Carbon Anodes

Silicon-carbon composites increase capacity but expand during cycling.

Engineering trade-offs:

-

Higher energy density

-

Increased swelling risk

-

Requires careful electrolyte and binder design

Silicon-carbon anodes are typically reserved for high-end or space-critical designs.

2.3 Electrolyte Formulation: Controlling Aging and Swelling

Electrolyte chemistry plays a major role in pouch cell stability.

Key functions:

-

Ion transport efficiency

-

High- and low-temperature performance

-

Gas generation control

-

Long-term aging behavior

Engineering detail:

Electrolyte additives are often customized for thin lithium polymer cells to reduce gas formation, which directly impacts swelling and cosmetic integrity.

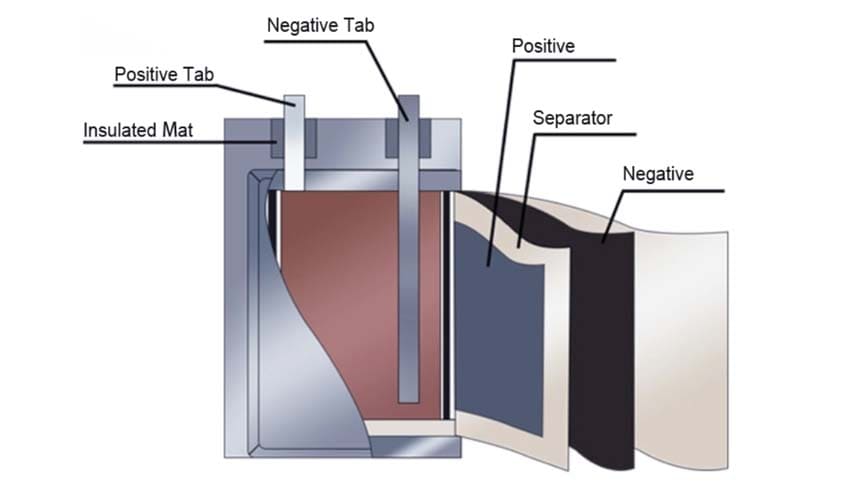

2.4 Separator Technology: Safety at the Core

Separators prevent internal short circuits while allowing ion flow.

|

Common materials: |

Separator selection affects: |

|

|

2.5 Aluminum-Plastic Film: The Backbone of Li-Po Design

|

Aluminum-plastic film enables: |

Engineering considerations: |

|

|

|

Poor-quality pouch film often leads to premature swelling or leakage, even when cell chemistry is well designed.

3. Midstream Supply Chain: Manufacturing and Engineering Integration

The midstream stage is where real-world battery performance is determined. It represents the highest technical barrier and the greatest value creation.

3.1 Electrode Coating and Calendaring

Uniform electrode coating ensures:

-

Consistent capacity

-

Stable internal resistance

-

Uniform current distribution

Calendaring controls electrode density and thickness, directly influencing energy density and cycle life.

3.2 Cell Stacking vs. Winding

Lithium polymer batteries almost exclusively use stacked cell architecture.

Advantages:

-

Better thickness control

-

Improved space utilization

-

Reduced internal stress

Stacked cells are essential for ultra-thin and flat battery designs.

3.3 Electrolyte Filling and Pouch Sealing

Electrolyte wetting quality affects:

-

Initial capacity

-

Internal resistance

-

Long-term stability

Sealing quality is critical for preventing moisture ingress, especially for medical and long-life devices.

3.4 Formation, Aging, and Cell Grading

Formation activates the electrochemical system.

After formation:

-

Cells undergo aging

-

Early failures are screened out

-

Cells are graded by capacity and impedance

This process is essential for applications requiring high consistency.

3.5 Pack-Level Engineering: Where Customization Happens

Most OEM customers require battery packs, not bare cells.

Customization areas:

-

Voltage and capacity configuration

-

PCM / BMS protection logic

-

Connector and cable design

-

Mechanical integration

-

Charging parameter optimization

Engineering Case Example

|

Engineering Case Example 1: Medical Monitoring Device

|

Engineering Case Example 2: GPS Tracking Device

|

|

Requirements:

Solution:

Result:

|

Requirements:

Solution:

Result:

|

4. Testing, Quality Control, and Reliability Validation

Professional lithium polymer battery manufacturers implement multi-layer testing:

-

Electrical performance tests

-

Cycle life validation

-

High/low temperature testing

-

Mechanical stress testing

-

Aging and storage tests

Testing ensures batteries perform reliably under real-world conditions.

5. Certification and Regulatory Compliance

Professional lithium polymer battery manufacturers provide full testing and compliance support, including:

-

UN 38.3 (transportation)

-

IEC 62133 (safety)

-

UL standards (cell or pack)

-

MSDS and shipping documentation

Experienced suppliers help OEMs navigate certification efficiently.

6. Downstream: Applications and End-Use Markets

The downstream segment defines how lithium polymer batteries are used and what performance characteristics are required.

Medical Devices |

Wearables and Smart Devices

|

|

Lithium polymer batteries are widely used in portable medical equipment such as:

Medical applications demand high safety, consistency, and certification compliance, making custom battery solutions essential. |

Wearables require:

Lithium polymer batteries are ideal for smartwatches, fitness trackers, and health monitoring wearables. |

IoT and GPS Devices

|

Consumer & Industrial Electronics

|

|

IoT applications prioritize:

Custom lithium polymer batteries enable optimized power management for sensors and tracking devices. |

From smart home devices to portable industrial instruments, lithium polymer batteries support applications where space efficiency and reliability are critical. |

7. Why Midstream Capability Defines Supplier Value

Upstream materials define potential, and downstream applications define demand.

Midstream engineering defines success.

OEMs benefit from:

-

Faster development cycles

-

Lower redesign risk

-

Improved safety

-

Stable long-term supply

8. Choosing the Right Lithium Polymer Battery Partner

When selecting a lithium polymer battery supplier, OEMs should evaluate:

-

Engineering and customization capability

-

Experience in target applications

-

Quality control and testing standards

-

Certification and compliance support

-

Long-term production stability

A reliable battery partner does more than supply power — they support product success from concept to mass production.

Conclusion

The lithium polymer battery supply chain is a tightly integrated system where materials, manufacturing, and application requirements must align. OEMs that understand this structure are better positioned to select reliable partners and build successful products.

For custom, compact, and safety-critical devices, choosing an experienced lithium polymer battery manufacturer is a strategic decision—not just a sourcing choice.

FAQ – Lithium Polymer Battery Supply Chain

1: What is the lithium polymer battery supply chain?

The lithium polymer battery supply chain includes upstream raw materials, midstream battery manufacturing and customization, and downstream applications such as medical devices, wearables, and IoT products.

2: What materials are used in lithium polymer batteries?

Lithium polymer batteries use cathode materials such as LCO or NCM, graphite-based anodes, organic electrolytes, polymer separators, and aluminum-plastic pouch film.

3: Why is midstream manufacturing important for custom Li-Po batteries?

Midstream manufacturing determines real-world performance, safety, consistency, and compliance. Customization at this stage ensures the battery fits the specific electrical and mechanical requirements of the device.

4: Are lithium polymer batteries suitable for medical devices?

Yes. Lithium polymer batteries are widely used in medical devices due to their compact size, stable performance, and ability to meet safety and certification requirements when properly engineered.

5: How do I choose a lithium polymer battery supplier?

OEMs should evaluate engineering capability, customization experience, quality control systems, certification support, and long-term supply stability.

-

May.2026.03.03Sodium Batteries and Lithium-Ion Batteries: Low-End Substitutes or Strategic Complements?Learn More

May.2026.03.03Sodium Batteries and Lithium-Ion Batteries: Low-End Substitutes or Strategic Complements?Learn More -

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More -

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More -

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More -

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More