18650 vs 18500 vs 21700 Batteries: Differences, Comparison & Selection Guide

Table of Contents

1. Introduction

As a battery supplier and technical consultant, we encounter frequent questions regarding 18650, 18500, and 21700 lithium-ion batteries. Understanding their differences is critical for battery pack design, energy storage systems, and industrial applications.

This guide will help you compare these battery types in terms of size, capacity, performance, safety, certifications, and procurement considerations.

2. Battery Naming Standards

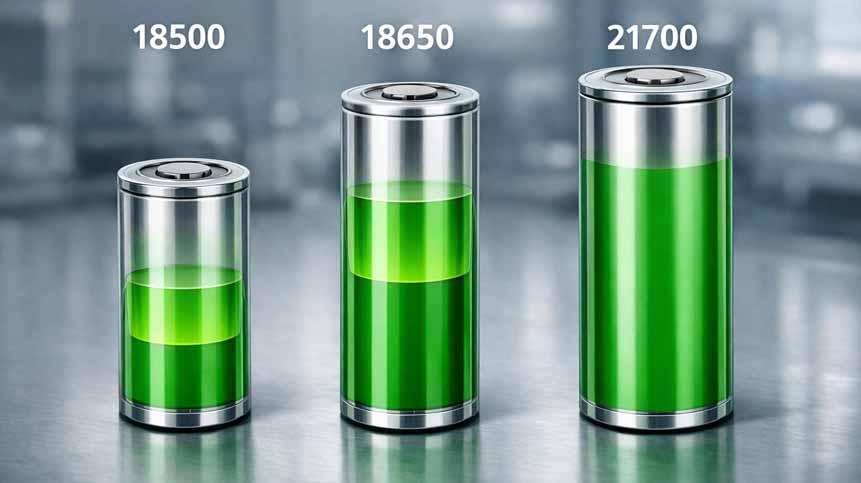

The numbers in battery names indicate diameter and length:

- 18500: 18mm diameter × 50mm length

- 18650: 18mm diameter × 65mm length

- 21700: 21mm diameter × 70mm length

Standardization simplifies procurement, integration, and regulatory compliance. Cylindrical cells are dominant in industrial applications, while prismatic and pouch cells serve niche devices.

External Reference: Battery University – Types of Lithium-Ion Cells

3. Physical Size & Dimensions

| Battery Type | Diameter (mm) | Length (mm) | Volume (cm³) | Weight (g) |

|---|---|---|---|---|

| 18500 | 18 | 50 | 12.7 | 35–38 |

| 18650 | 18 | 65 | 16.5 | 45–48 |

| 21700 | 21 | 70 | 24.2 | 65–70 |

21700 cells provide higher capacity and fewer cells per pack. 18500 is ideal for compact devices. 18650 is widely used and cost-efficient.

4. Capacity & Energy Density

Typical Capacities:

- 18500: 1200–1500 mAh

- 18650: 2000–3500 mAh

- 21700: 4000–5000 mAh

Energy Density:

- 18500: ~220 Wh/kg

- 18650: ~240 Wh/kg

- 21700: ~260 Wh/kg

| Battery | Internal Resistance (mΩ) | Continuous Discharge (A) | Cycle Life |

|---|---|---|---|

| 18500 | 40–50 | 2–5 | 300–400 |

| 18650 | 20–30 | 5–15 | 500–800 |

| 21700 | 15–25 | 10–20 | 800–1000 |

21700 is optimal for high-discharge industrial applications, 18500 for compact low-power devices, and 18650 for balanced mid-range use.

Reference: NREL – Lithium-ion Cell Performance Metrics

5. Application Scenarios

- 18500: portable medical devices, LED lights, lab instruments

- 18650: laptops, e-bikes, power banks, medical devices

- 21700: EVs, industrial energy storage, high-power tools

6. Safety & Certifications

Essential Certifications for B2B Applications:

- UN38.3 – Transport safety

- IEC 62133 – Electrical safety

- UL Certification – Consumer safety

BMS integration is critical to protect against overcharge, over-discharge, and thermal runaway.

External Reference: UL Lithium Battery Standards

7. Cost & Supply Chain

| Battery | Cost per Cell | Supplier Availability | MOQ |

|---|---|---|---|

| 18500 | Low | Limited | 5000 pcs |

| 18650 | Medium | High | 1000 pcs |

| 21700 | High | Medium | 500 pcs |

8. How to Choose the Right Battery

- Assess energy requirements

- Consider space and weight constraints

- Check discharge rate and cycle life

- Verify certifications (UN38.3, IEC 62133, UL)

- Evaluate supplier reliability and batch testing

- Consider customization options

9. Comparison Table

| Feature | 18500 | 18650 | 21700 |

|---|---|---|---|

| Diameter (mm) | 18 | 18 | 21 |

| Length (mm) | 50 | 65 | 70 |

| Capacity (mAh) | 1200–1500 | 2000–3500 | 4000–5000 |

| Energy Density (Wh/kg) | 220 | 240 | 260 |

| Continuous Discharge (A) | 2–5 | 5–15 | 10–20 |

| Cycle Life | 300–400 | 500–800 | 800–1000 |

| Weight (g) | 35–38 | 45–48 | 65–70 |

| Applications | Portable devices | Laptops, e-bikes | EVs, industrial packs |

10. Market Trends

- 21700 demand rising in EV and industrial storage

- 18500 remains for portable electronics and medical devices

- Supply chain: China, South Korea, Japan dominant; plan procurement

External Reference: BloombergNEF – Battery Market Outlook

11. Frequently Asked Questions

12. Conclusion

Choosing between 18500, 18650, and 21700 batteries requires careful assessment of size, capacity, cycle life, safety, and supply reliability.

18500: compact, low-energy devices

18650: balanced mid-range choice

21700: high-capacity, high-discharge applications like EVs and industrial storage

At A&S Power, we provide certified lithium-ion cells and customized battery packs for B2B clients. Contact us for inquiries .

-

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More -

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More -

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More -

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More -

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More