18650 Battery Performance Degradation in Low Temperatures: How to Improve Runtime Stability?

18650 lithium-ion batteries are widely used in flashlights, medical devices, portable electronics, industrial tools, energy storage modules, and mobility products. Under standard conditions, they deliver reliable energy density, stable voltage, and long cycle life. However, once ambient temperatures drop below 10°C (50°F), many users experience a sudden and sometimes dramatic decline in performance.

Symptoms often include reduced usable capacity, noticeable voltage sag under load, slower charging, and shortened runtime. In extreme cases, devices shut down unexpectedly even when the battery appears partially charged.

This article explains why 18650 batteries degrade in cold environments, how temperature affects internal electrochemistry, and—most importantly—what practical, data-backed strategies can significantly improve runtime stability and safety in low-temperature applications.

1. Why Low Temperatures Affect 18650 Batteries

Low temperatures reduce 18650 battery performance because cold conditions slow lithium-ion movement in the electrolyte, increase internal resistance, and disrupt normal charge-transfer reactions at the electrodes.

1.1 Lithium-Ion Electrochemistry at Low Temperatures

18650 batteries operate by shuttling lithium ions between the anode and cathode through a liquid electrolyte. This process depends heavily on temperature.

When temperatures drop:

-

Electrolyte viscosity increases

-

Ion mobility decreases

-

Charge-transfer resistance rises

-

Reaction kinetics slow down

As a result, energy stored inside the battery becomes electrochemically inaccessible, even though it still physically exists.

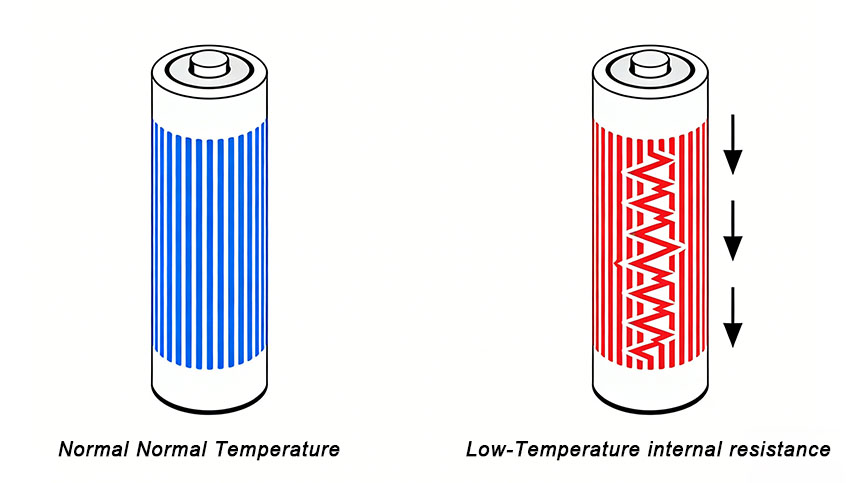

1.2 Internal Resistance Increase

One of the most critical effects of cold temperatures is increased internal resistance (IR).

| Temperature | Internal Resistance Change |

|---|---|

| 25°C (77°F) | Baseline (100%) |

| 0°C (32°F) | +35% to +60% |

| -10°C (14°F) | +70% to +120% |

| -20°C (-4°F) | +150% to +300% |

Higher resistance leads to:

-

Voltage drop under load

-

Reduced power output

-

Premature low-voltage cutoff by BMS/PCM

This explains why devices may shut down suddenly in cold environments.

1.3 Capacity Loss vs. Energy Availability

It is important to clarify: low temperature does not permanently remove capacity, but it temporarily limits usable capacity.

At -20°C, an 18650 battery may only deliver 50–60% of its rated capacity, depending on chemistry and discharge rate.

2. Charging Risks of 18650 Batteries in Cold Environments

Charging 18650 batteries below 0°C can cause lithium plating on the anode, leading to irreversible capacity loss and increased safety risks.

2.1 Lithium Plating Mechanism

At low temperatures:

-

Lithium ions cannot intercalate into the graphite anode fast enough

-

Metallic lithium deposits form on the anode surface

-

These deposits do not fully reintegrate during discharge

This phenomenon is called lithium plating, and it is one of the most damaging failure modes in lithium-ion batteries.

2.2 Long-Term Effects of Cold Charging

| Impact | Consequence |

|---|---|

| Lithium plating | Permanent capacity loss |

| Dendrite formation | Internal short-circuit risk |

| Increased IR | Reduced runtime |

| Accelerated aging | Shortened cycle life |

For this reason, reputable manufacturers strongly recommend not charging 18650 cells below 0°C (32°F).

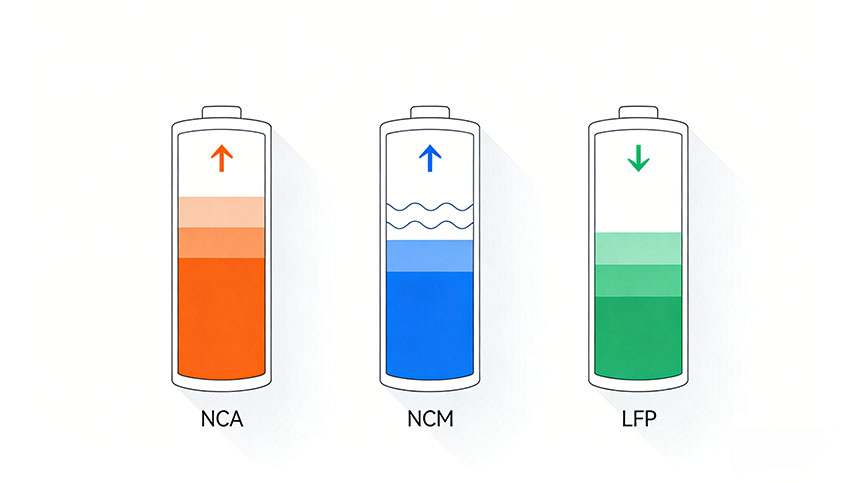

3. Chemistry Matters: Which 18650 Cells Perform Better in the Cold?

Not all 18650 batteries behave the same at low temperatures.

3.1 Comparison of Common Lithium Chemistries

| Chemistry | Low-Temperature Performance | Notes |

|---|---|---|

| NCA (Nickel Cobalt Aluminum) | Excellent | Low IR, high energy density |

| NCM / NMC | Very Good | Balanced performance |

| LCO | Moderate | Aging accelerates in cold |

| LFP (LiFePO4) | Poor | High IR at low temperature |

3.2 Why LFP Performs Worse in Cold Weather

LFP chemistry has:

-

Lower lithium-ion diffusion rates

-

Higher charge-transfer resistance

-

Stronger temperature sensitivity

This makes LFP less suitable for cold outdoor applications unless heating systems are used.

4. Real-World Performance Data of 18650 Batteries at Low Temperatures

Discharge Capacity vs. Temperature (Typical 2.5V Cutoff)

| Temperature | Available Capacity |

|---|---|

| 25°C | 100% |

| 10°C | 90–95% |

| 0°C | 75–85% |

| -10°C | 60–70% |

| -20°C | 45–60% |

(Data compiled from industry testing and manufacturer datasheets)

4.1 Impact of Discharge Rate (C-Rate)

Higher discharge currents worsen cold performance.

| Discharge Rate | Capacity at -10°C |

|---|---|

| 0.2C | ~75% |

| 0.5C | ~65% |

| 1C | ~50% |

| 2C | <40% |

High-drain cells are engineered to minimize this effect.

5. How to Improve Runtime Stability in Cold Environments

5.1 Choose Cold-Optimized 18650 Cells

When selecting cells:

-

Look for -20°C discharge rating

-

Prefer NCA or NCM chemistries

-

Use cells from reputable manufacturers

-

Avoid recycled or counterfeit cells

For high-drain devices, select 10C or higher discharge-rated cells.

5.2 Optimize Battery Storage and Preheating

Simple habits can dramatically improve performance:

-

Store batteries close to body heat

-

Use insulated battery cases

-

Avoid leaving batteries in vehicles overnight

-

Pre-warm batteries before use

Even raising cell temperature by 5–10°C can restore significant capacity.

5.3 Avoid Deep Discharge in Cold Weather

Deep discharge below 20% SOC in cold conditions:

-

Increases stress on electrodes

-

Accelerates degradation

-

Raises internal resistance permanently

Recharge batteries as soon as possible in a 15–25°C environment.

5.4 Smart Charging Practices

-

Never charge below 0°C

-

Use chargers with temperature compensation

-

Allow batteries to warm naturally before charging

-

Reduce charging current in cold conditions

6. Hardware-Level Solutions for Cold Environments

6.1 Thermal Insulation Design

-

Foam or aerogel insulation

-

Double-layer battery compartments

-

Reduced airflow exposure

6.2 Parallel Cell Configurations

Parallel packs:

-

Reduce per-cell current

-

Lower voltage drop

-

Improve runtime stability

Ensure all cells are matched in capacity and internal resistance.

6.3 Active Heating Systems

Some industrial and medical applications use:

-

Resistive heaters

-

Self-heating battery designs

-

BMS-controlled warming circuits

These must be carefully controlled to avoid overheating.

7. Monitoring Battery Health in Cold Applications

7.1 Capacity Degradation Indicators

Replace cells when:

-

Runtime drops >20%

-

Voltage sag increases noticeably

-

Cells heat abnormally under load

7.2 Safety Inspection Checklist

-

No swelling

-

No leakage

-

No unusual odor

-

Stable temperature during discharge

8. Future Technologies for Low-Temperature Lithium Batteries

Emerging solutions include:

-

Low-viscosity electrolyte additives

-

Silicon-doped anodes

-

Advanced SEI-forming additives

-

Self-heating lithium-ion cells

These technologies show promising improvements down to -30°C, but are not yet widely commercialized.

A&S Power Engineering Perspective

A&S Power has over 15 years of experience in lithium battery design and manufacturing, supplying customized 18650 battery packs for:

-

Medical devices

-

Outdoor electronics

-

Industrial instruments

-

GPS and wearable products

Our engineering team designs battery solutions optimized for low-temperature environments, including:

-

Chemistry selection

-

Cell matching

-

PCM/BMS optimization

-

Thermal design strategies

This article is based on real manufacturing data, laboratory testing, and field feedback from global customers.

Recommendations

Conclusion

Low temperatures are an unavoidable challenge for 18650 lithium-ion batteries, but their impact can be significantly reduced through informed cell selection, proper usage habits, intelligent charging, and thoughtful system design.

By understanding the underlying electrochemical mechanisms and applying proven mitigation strategies, users and manufacturers can achieve stable, reliable battery performance—even in harsh, cold environments.

-

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More -

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More -

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More -

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More -

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More