Contents

- 1. The Shift to Portability: Why Medical OEMs Demand Custom LiPo Batteries

- 2. Lithium-Ion vs. Lithium Polymer: Which Chemistry Fits Your Medical Application?

- 3. The Standard: Safety, Certifications, and ISO 9001 Compliance

- 4. Engineering Precision: Customizing Shape, PCM, and BMS for Healthcare Wearables

- 5. Case Studies: Empowering Next-Gen Ventilators and Portable Ultrasounds

- 6. Future Trends 2026: AI-Integrated Diagnostics and Fast-Charging Medical Packs

- 7. Choosing the Right Custom Battery Partner in the US Market

In the rapidly evolving landscape of the American healthcare industry, the demand for "smaller, lighter, and more reliable" has never been higher. As portable diagnostic tools and wearable health monitors become the gold standard for patient care, the heart of these devices—the custom LiPo battery—has moved to the forefront of medical engineering.

At A&S Power, we recognize that a medical-grade power solution is not just a component; it is a life-critical system. Whether it is a lithium-ion battery for a high-drain surgical tool or a flexible lithium polymer battery for a continuous glucose monitor, the engineering requirements in the US market are among the most stringent in the world. Our mission is to bridge the gap between high-capacity energy needs and the strict safety mandates of the FDA and other regulatory bodies.

The Shift to Portability: Why Medical OEMs Demand Custom LiPo Batteries

The transition from corded hospital equipment to untethered, mobile solutions is a defining trend of 2026. Medical Original Equipment Manufacturers (OEMs) are increasingly moving away from off-the-shelf cells toward custom LiPo battery packs. This shift is driven by the need for better patient mobility and the rise of telehealth services across North America.

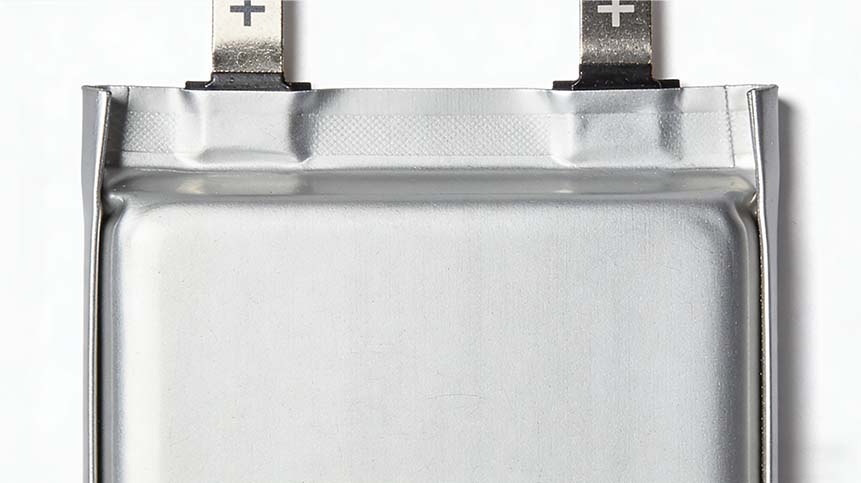

Unlike standard cylindrical cells, LiPo (Lithium Polymer) technology offers unparalleled "form factor freedom." In an industry where device ergonomics directly impact clinical outcomes, the ability to design a battery that fits into the curved handle of a handheld scanner or the ultra-thin housing of a chest patch is a game-changer. By leveraging custom lithium polymer battery designs, engineers can maximize energy density without compromising the device's aesthetic or functional integrity.

Lithium-Ion vs. Lithium Polymer: Which Chemistry Fits Your Medical Application?

Choosing the right chemistry is the first step in successful medical device engineering. While both are lithium-based, their physical and electrochemical properties serve different purposes in a healthcare setting.

| Feature | Custom Lithium-Ion (Li-ion) | Custom Lithium Polymer (LiPo) |

|---|---|---|

| Form Factor | Rigid (Cylindrical or Prismatic) | Flexible (Thin Pouch) |

| Energy Density | Very High | High (Weight-efficient) |

| Typical Use | Ventilators, X-ray Machines | Wearables, Patient Monitors |

| Cost Profile | Lower for high volume | Slightly higher due to customization |

For high-capacity applications like portable oxygen concentrators, a custom lithium-ion battery pack (often using 18650 or 21700 cells) provides the necessary longevity. However, for wearables, the lithium polymer battery is superior because it avoids the "metal can" weight, allowing for a more comfortable patient experience.

The Standard: Safety, Certifications, and ISO 9001 Compliance

For the US medical market, A medical custom Li-ion battery must meet more than just basic electrical specs; it must be a fortress of safety.

- IEC 62133-2: Global safety standard for portable lithium cells.

- UL 2054: Essential for passing US insurance and hospital safety audits.

- UN38.3: Mandatory for the air shipment of any lithium battery products into the USA.

At A&S Power, our manufacturing processes are aligned with ISO 9001 Quality Management Systems. This ensures every custom LiPo battery undergoes rigorous traceability and risk assessment before reaching an American clinic. Our quality control team utilizes automated X-ray inspection to ensure the internal alignment of pouch cells, preventing the latent defects that lead to field failures.

Engineering Precision: Customizing Shape, PCM, and BMS for Healthcare Wearables

In a medical application, "custom" goes beyond dimensions. It involves the integration of a sophisticated Battery Management System (BMS) or Protection Circuit Module (PCM). This is the "brain" of the battery that ensures the safety of both the device and the patient.

When designing for the US healthcare sector, we focus on:

- Redundant Safety Circuits: Preventing overcharge, over-discharge, and short-circuits is mandatory for patient-contact devices.

- Precision Fuel Gauging: Doctors need 1% accuracy in battery life readings for mission-critical devices like ventilators. We integrate ICs from TI or Maxim to provide real-time SOC (State of Charge) data.

- Biocompatible Materials: For wearables, the outer casing and connectors must resist skin irritation and survive repeated medical-grade disinfection.

Case Studies: Empowering Next-Gen Ventilators and Portable Ultrasounds

Real-world results are the ultimate proof of authority. By analyzing data from our high-interaction pages, we've identified two key areas where our custom lithium-ion battery solutions have made a significant impact:

Case Study 1: The Remote Patient Monitor

A Silicon Valley startup required a custom lithium polymer battery for a 24-hour cardiac wearable. By utilizing a high-energy 3.7V LiPo pouch with a specialized ultra-thin PCM, A&S Power extended the device's runtime by 30% while reducing total weight by 15 grams.

Similarly, for handheld ultrasound devices, which require rapid bursts of power, our [custom battery packs](https://www.szaspower.com/products/) utilize high-discharge cells that maintain voltage stability even during intensive imaging cycles.

Future Trends 2026: AI-Integrated Diagnostics and Fast-Charging Medical Packs

As we look toward the second half of 2026, the next frontier of medical application batteries involves "Smart Power." As AI algorithms now run locally on medical handhelds to provide instant diagnosis, the energy draw is becoming more dynamic and demanding.

We are seeing a rise in demand for custom LiPo batteries featuring Graphene-enhanced electrodes. These allow for ultra-fast charging—critical for emergency room equipment that cannot afford long downtime. Additionally, extreme temperature stability is becoming a priority for emergency rescue equipment used in diverse American environments, from the frigid Alaskan winters to the intense heat of Arizona.

Choosing the Right Custom Battery Partner in the US Market

Selecting a manufacturer for your custom LiPo battery is a strategic decision that affects your product's time-to-market and regulatory approval success. US-based engineers often prefer partners who can provide rapid prototyping, transparent technical documentation, and proactive communication.

A&S Power distinguishes itself by offering full OEM/ODM support. From initial cell selection to the final enclosure design, we provide the full data sets required for FDA 510(k) submissions. Our expertise ensures that your lithium-ion battery or lithium polymer battery project moves seamlessly from concept to mass production.

Ready to Power Your Next Medical Innovation?

Consult with our engineers today for a custom power solution tailored to the US medical market. Get a quote within 24 hours.

Trust A&S Power – Your Professional And Reliable Battery Partner.