LiPo Battery Voltage Tester: A Complete Professional Guide

LiPo Battery Voltage Tester – What It Is, Why It Matters, and How to Use It Correctly

As a lithium battery engineer working closely with lithium polymer (LiPo) cells for consumer electronics, medical devices, RC applications, and industrial equipment, I can say this clearly:

Incorrect voltage monitoring is one of the most common causes of:

-

Premature LiPo battery failure

-

Swelling and internal gas generation

-

Over-discharge damage

-

Fire and thermal runaway risks

Incorrect voltage monitoring is one of the most common causes of premature battery failure, swelling, over-discharge damage, and even thermal runaway. In this guide, I explain how LiPo battery voltage testers work, why voltage accuracy matters, and how to select the right tester for your application.

What Is a LiPo Battery Voltage Tester?

A LiPo battery voltage tester is a device used to measure:

-

Total pack voltage

-

Individual cell voltage

-

Cell balance consistency

-

State of charge (SoC)

Unlike simple multimeters, LiPo voltage testers are specifically designed to read multi-cell lithium polymer battery packs through balance connectors (JST-XH, EH, etc.).

Why LiPo Batteries Require Dedicated Voltage Testers

- Operate within narrow voltage windows

- Are extremely sensitive to overcharge and over-discharge

- Can become unsafe if a single cell drifts out of balance

A standard multimeter cannot easily detect individual cell imbalance, which is where most failures begin.

Standard Voltage Ranges of LiPo Batteries

Understanding correct voltage ranges is critical before using any tester.

| Battery State | Voltage per Cell (V) | Risk Level |

|---|---|---|

| Fully Charged | 4.20 | Normal |

| Storage Voltage | 3.80 – 3.85 | Optimal |

| Nominal Voltage | 3.70 | Normal |

| Low Voltage Warning | 3.30 – 3.40 | Caution |

| Over-Discharge | < 3.00 | Damage Risk |

Industry Reference: IEC 62133, UL 1642, UN38.3 testing data.

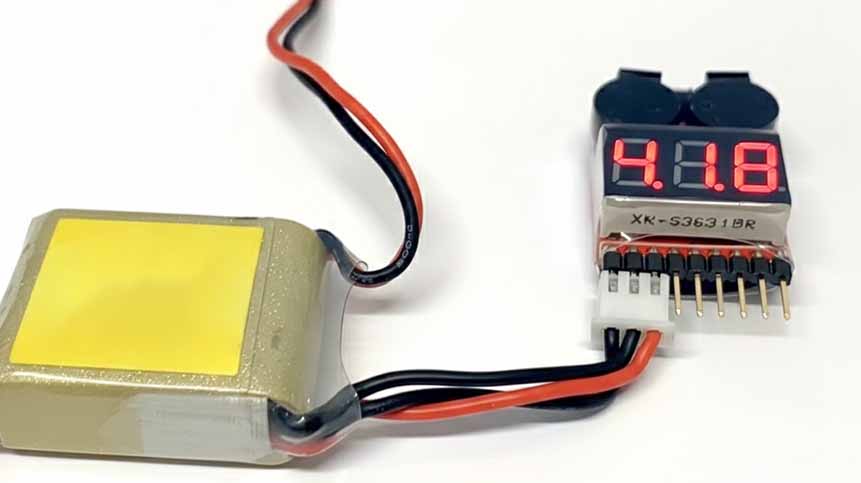

How a LiPo Battery Voltage Tester Works

Measurement Principles

A LiPo voltage tester works by:

-

Connecting to the balance port

-

Measuring each cell’s voltage individually

-

Calculating:

-

Total voltage

-

Cell deviation (ΔV)

-

Voltage stability

-

Why Cell-Level Measurement Matters

A 3S LiPo pack may show 11.1V total, yet one cell could already be:

-

At 3.0V (damaged)

-

While others remain at 4.0V

This imbalance cannot be detected without a cell voltage tester.

Types of LiPo Battery Voltage Testers

Basic LED / LCD Voltage Checkers

Best for: RC hobbyists, drone users |

Smart Digital LiPo Voltage Testers

Best for: Professional maintenance, battery labs |

Integrated BMS-Based Voltage Monitoring

Best for: Medical devices, industrial batteries |

Why Voltage Testing Is Critical for LiPo Battery Safety

Preventing Over-Discharge DamageOver-discharging below 3.0V per cell causes:

Once this occurs, no charger can recover the battery safely. |

Early Detection of Swelling and FailureVoltage imbalance is often the first measurable symptom before:

This is why we always test voltage before physical inspection. |

Voltage Imbalance – Real Data Example

Cell Imbalance Thresholds

| Cell Deviation | Condition |

|---|---|

| ≤ 0.03V | Excellent |

| 0.04–0.07V | Acceptable |

| 0.08–0.10V | Warning |

| > 0.10V | Replace Battery |

Professional battery manufacturers generally reject packs exceeding 0.1V imbalance during aging tests.

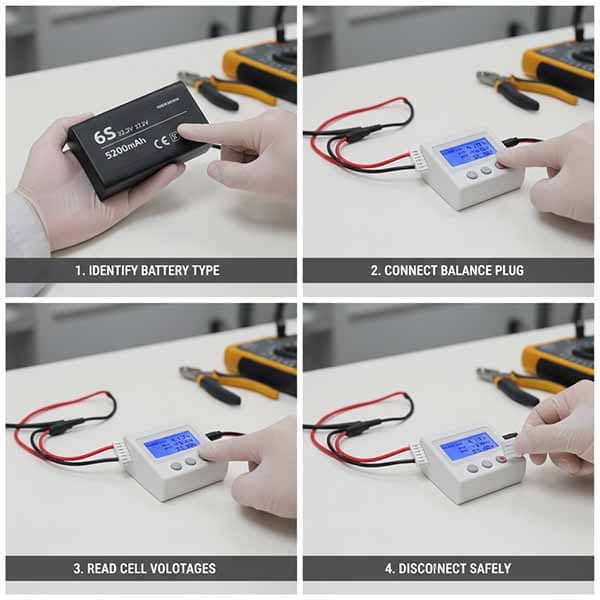

How to Use a LiPo Battery Voltage Tester (Step-by-Step)

Step 1 – Identify Battery ConfigurationExamples:

|

Step 2 – Connect to Balance Port CorrectlyAlways:

|

Step 3 – Interpret Results ProfessionallyDo not only look at: Instead evaluate: |

LiPo Voltage Tester vs Multimeter

| Feature | LiPo Voltage Tester | Multimeter |

|---|---|---|

| Cell-level reading | Yes | No |

| Balance analysis | Yes | No |

| Alarm function | Yes | No |

| Ease of use | High | Medium |

| Safety | High | Low |

Selecting the Right LiPo Battery Voltage Tester

Key Selection Criteria

-

Voltage accuracy (≤ ±0.02V)

-

Cell count compatibility

-

Alarm customization

-

Connector compatibility

-

Build quality

For B2B or industrial use, I always recommend calibrated digital testers over hobby-grade devices.

Applications of LiPo Battery Voltage Testers

-

RC cars & drones

-

Medical equipment batteries

-

Wearable electronics

-

Backup power systems

-

Custom lithium battery packs

LiPo Battery Voltage Testing in Manufacturing (Professional Insight)

In our production lines, voltage testing is performed at:

-

Post-assembly

-

Aging test

-

Final inspection

-

Pre-shipment QA

Voltage testers here are calibrated instruments, not consumer devices.

Common Mistakes When Testing LiPo Voltage

-

Ignoring cell imbalance

-

Measuring immediately after heavy load

-

Testing without temperature stabilization

-

Using damaged balance connectors

FAQ – LiPo Battery Voltage Tester

What is the safe voltage range for a LiPo battery?

Safe operation is between 3.0V and 4.2V per cell. Storage voltage should be around 3.8V.

Can I use a multimeter instead?

A multimeter cannot detect individual cell imbalance, which is critical for safety.

How often should I test LiPo battery voltage?

Before use, after heavy discharge, and before long-term storage.

References

Final Professional Takeaway

From an engineering and safety standpoint, a LiPo battery voltage tester is one of the most cost-effective tools to prevent battery failure and safety incidents.

Whether you are:

-

An RC user

-

A device manufacturer

-

Or sourcing custom LiPo battery packs

Accurate voltage monitoring is non-negotiable.

If you need custom lithium polymer batteries with integrated voltage protection and testing, feel free to explore our solutions or contact our engineering team.

-

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More -

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More -

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More -

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More -

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More