Lithium Battery Protection Board: Principles, Key Parameters, and Troubleshooting Guide

Introduction: Why Lithium Battery Protection Boards Matter

Lithium batteries—such as lithium-ion (Li-ion), lithium-polymer (LiPo), and lithium iron phosphate (LFP)—are now the power source behind consumer electronics, medical equipment, industrial devices, robotics, wearables, energy storage systems, and electric mobility. But despite their high energy density and long cycle life, lithium batteries are also highly sensitive electrochemical systems.

Without adequate protection, lithium cells can become unstable. Issues like overcharging, over-discharging, external short circuits, or high temperatures may trigger accelerated degradation, capacity fade, thermal runaway, or in worst cases, fire hazards.

This is where the lithium battery protection board—often referred to as a PCM (Protection Circuit Module) or part of a Battery Management System (BMS)—plays a crucial safety, stability, and longevity role.

This complete guide explains:

-

What a lithium battery protection board is

-

How it works

-

Core components and functions

-

Standard protection thresholds

-

Common faults and how to diagnose them

-

Repair and reset methods

-

Data-based insights for engineers, buyers, and technical decision makers

1. What Is a Lithium Battery Protection Board?

A lithium battery protection board is an electronic safety circuit built into lithium battery packs. Its primary function is to protect individual cells from electrical or thermal conditions that may cause damage or pose safety risks.

Core Functions

1.1 Charge and Discharge Protection

The protection board prevents:

-

Overcharge

-

Over-discharge

-

Over-current

-

Short circuit

-

Reverse wiring

-

Excessive temperature rise

When an abnormal condition occurs, the circuit disconnects the charging or discharging path by controlling MOSFET switches.

1.2 Cell Balancing Function

In multi-cell series packs (2S, 3S, 4S, etc.):

-

Cells charge at different speeds

-

Voltage imbalance shortens cycle life

-

The protection board enables active or passive balancing

-

It equalizes cells to maintain stable pack operation

Balancing improves:

-

Charging efficiency

-

Capacity utilization

-

Long-term durability

1.3 Real-Time Cell State Monitoring

Protection boards continuously monitor:

-

Cell voltage

-

Pack voltage

-

Charging and discharging current

-

Internal resistance

-

Temperature (via NTC or thermistors)

-

MOSFET operating status

When a parameter exceeds the safe threshold, the system activates a protective cutoff.

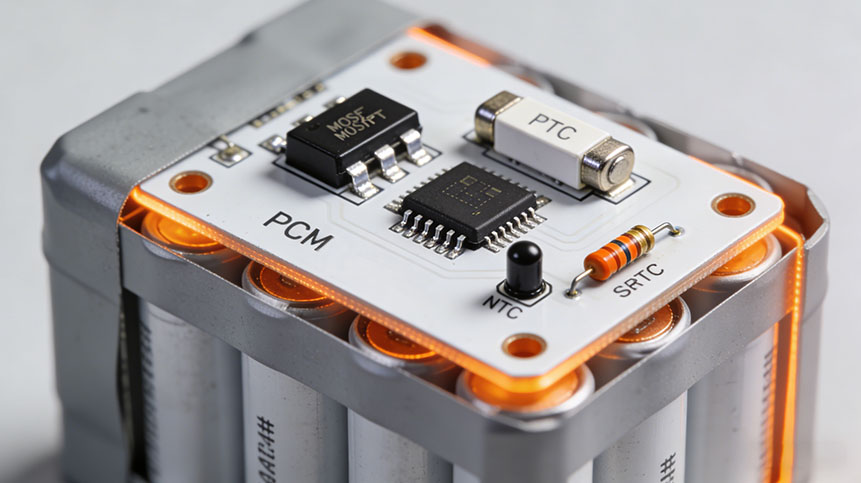

1.4 Auxiliary Protection Components

Some boards integrate auxiliary devices:

-

PTC (Positive Temperature Coefficient): increases resistance at high temperature

-

Fuse: provides irreversible protection

-

NTC sensor: temperature measurement for thermal shutdown

-

ID module / EEPROM: stores battery information

-

Memory components: store cycle count or protection logs

These additional elements increase reliability, especially in medical, aerospace, or industrial applications.

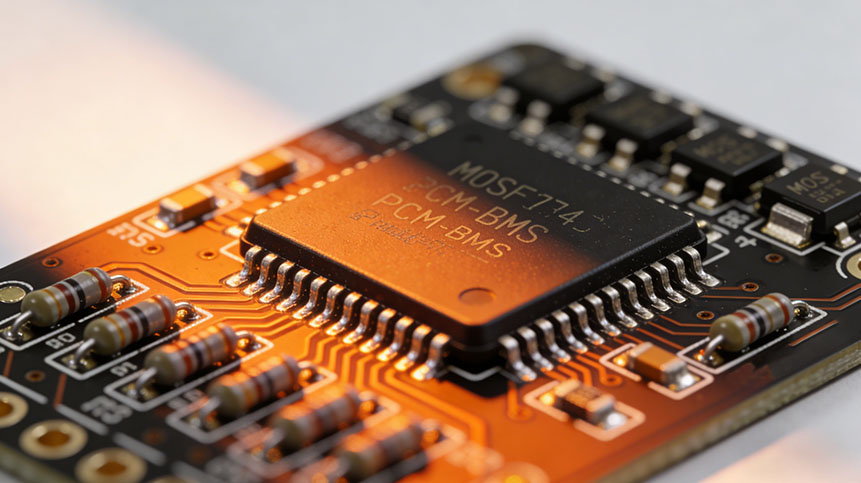

2. Key Components of a Lithium Battery Protection Board

A standard PCM includes both core electronics and auxiliaryprotective components.

2.1 Core Electronic Components

| Component | Function Description |

|---|---|

| Control IC | The brain of the protection board; monitors voltage/current/temperature. |

| MOSFETs | Switches that connect or disconnect the battery from load/charger. |

| Resistors | Voltage/current sampling, balancing circuits. |

| Capacitors | Stabilize the circuit to prevent oscillation. |

| Control logic circuits | Manage timing, thresholds, and switching sequences. |

2.2 Auxiliary Devices

| Component | Purpose |

|---|---|

| Fuse | Permanent cutoff protection against catastrophic failure. |

| PTC | Self-resetting over-temperature protection. |

| NTC | Temperature measurement to enable thermal shutdown. |

| EEPROM | Stores battery ID, cycle information, calibration values. |

| ID Chip | Authentication for smart batteries. |

These components together form the safety backbone of modern lithium battery packs.

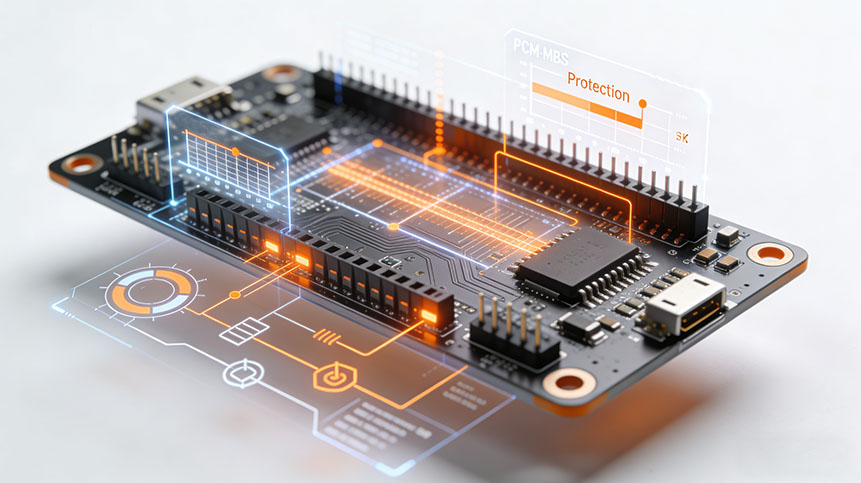

3. How a Lithium Battery Protection Board Works

The protection process depends on the coordination of control IC + MOSFETs + sensing circuits.

3.1 Environmental Adaptation

Most protection boards operate reliably from −40°C to +85°C, allowing usage in:

-

Outdoor devices

-

Automotive electronics

-

Industrial equipment

-

Consumer products

The board continuously samples:

-

Voltage (cell and total pack)

-

Current (charge/discharge)

-

Temperature

3.2 Normal Operating Mode

Under normal conditions:

-

The control IC activates MOSFET switches

-

The battery remains connected

-

Charging and discharging proceed normally

The circuit dynamically adjusts to maintain safe operation.

3.3 Abnormal Protection Mode

If any parameter exceeds the safe range, the system triggers protection.

Examples:

| Abnormal Condition | Typical Trigger Level | Protection Action |

|---|---|---|

| Overcharge | >4.25V per cell (Li-ion) | Stop charging |

| Over-discharge | <2.5–2.8V per cell | Stop discharging |

| Over-current | >10–60A depending on pack | Cut off MOSFET |

| Short circuit | Instant high current | Immediately disconnect |

| High temperature | >60°C (charging), >70°C (discharging) | Thermal shutdown |

MOSFETs disconnect the circuit within microseconds.

3.4 High-Temperature Auxiliary Mechanism

A PTC increases resistance dramatically when overheated, reducing current flow and preventing further damage.

This feature adds redundancy to the electrical cutoff.

4. Standard Voltage Protection Thresholds

Different lithium chemistries have different voltage limits. The protection board must match the cell type.

4.1 Common Voltage Protection Ranges

| Battery Chemistry | Typical Over-Charge Cutoff | Typical Over-Discharge Cutoff |

|---|---|---|

| Ternary Li-ion (NMC/NCA) | 4.20–4.25V | 2.8–3.0V |

| LFP (LiFePO4) | 3.60–3.65V | 2.5–2.8V |

| LiPo (Polymer) | 4.20V | 3.0V |

| High-voltage Li-ion | 4.35–4.40V | 2.8–3.0V |

4.2 Impact of Incorrect Thresholds

If thresholds do not match the chemistry:

-

Over-charging → gas generation, swelling, thermal runaway

-

Over-discharging → copper dissolution, permanent damage

-

Incorrect high-temp cutoff → internal short risks

Using a chemistry-matched PCM is essential for safety and cycle life.

5. Common Issues and Faults in Lithium Battery Protection Boards

This section answers the question directly — “What are the common faults of lithium battery protection boards and how do I diagnose them?”

5.1 Failure of Charge/Discharge Function

When a protection board stops charging or discharging, consider these causes:

1. Protection Triggered

The board might have entered:

-

Over-charge protection

-

Over-discharge protection

-

Over-current protection

-

Short-circuit protection

-

Temperature protection

2. MOSFET Failure

Use a multimeter to test MOSFET drain-source continuity.

3. LED Alarm

Some boards flash:

-

0.5-second intervals indicate a protection state

4. PC Software Monitoring

Smart BMS/PCM can connect to a laptop/software to view:

-

Protection logs

-

Cell voltage data

-

Error codes

5. External Switch Issue

Some PCM designs include a:

-

Low-power consumption switch

Ensure it is turned ON.

5.2 How to Diagnose a Damaged Protection Board

These simple tests determine whether the PCM is genuinely damaged.

1. Charging Test

If:

-

The charger cannot activate

-

The battery does not accept charge

-

Capacity remains zero

→ Possible protection circuit damage.

2. Output Voltage Test

If output voltage = 0V, but the cell is not dead → strong indication of PCM failure.

3. Distinguish Lockout vs. Damage

Some PCMs enter a temporary lockout due to:

-

Over-discharge

-

Short-circuit

-

Over-current events

Charging may reset the board.

6. Repair and Recovery Methods

6.1 Recovery from Protection Trigger

Over-charge, over-discharge, or short-circuit events can often be reset by:

-

Connecting a compatible charger

-

Allowing the PCM to reinitialize

6.2 Over-Current Recovery

Remove the load → PCM resets automatically.

6.3 Hardware Repair

If MOSFETs or ICs are physically damaged:

-

Replace MOSFETs

-

Replace the control IC

-

Examine solder joints and connectors

-

Inspect for burnt components under microscope

However, for commercial battery packs, replacing the PCM is often more cost-effective.

7. Data Insights: Why Protection Boards Fail

Based on industry manufacturing data (A&S Power internal manufacturing insights + public industry reports):

| Failure Cause | Occurrence Ratio | Notes |

|---|---|---|

| Over-current accidents | 32% | Often due to mismatched load |

| Over-discharge lockout | 27% | Common in devices unused for long periods |

| MOSFET thermal fatigue | 18% | Usually related to heat accumulation |

| Poor welding or connector looseness | 12% | Seen in low-cost PCM manufacturing |

| IC failure | 6% | Rare but serious |

| NTC sensor deviation | 5% | Causes false high-temperature triggers |

This data highlights why selecting a high-quality PCM manufacturer significantly impacts battery reliability.

Best Practices for Selecting a Lithium Battery Protection Board

Key Selection Checklist

-

Match chemistry (Li-ion, LiPo, LFP)

-

Confirm charge/discharge current ratings

-

Ensure correct voltage thresholds

-

Consider whether balancing is needed

-

Use UL/IEC-certified boards for medical/industrial devices

-

Evaluate MOSFET thermal performance

-

Choose a manufacturer with testing standards like:

-

UN38.3

-

IEC 62133

-

UL1642

-

UL2054

-

9. A&S Power Technical Expertise

A&S Power has manufactured lithium-ion and lithium-polymer batteries since 2010, supplying clients in:

-

Medical devices

-

Consumer electronics

-

Industrial instruments

-

Wearable devices

-

Robotics

-

GPS and mobility products

Our engineering team develops:

-

Custom BMS/PCM designs

-

Certified battery packs

-

High-precision balancing systems

-

Medical-grade battery protection circuits

10. Recommendations

Conclusion

Lithium battery protection boards are essential for ensuring the safety, reliability, and longevity of modern lithium battery packs. Understanding their working principles, voltage thresholds, common failures, and repair methods enables engineers, procurement managers, and technical teams to make informed decisions.

By applying proper diagnostics and selecting high-quality PCM/BMS components, companies can significantly reduce battery failures, product returns, and safety incidents.

A&S Power will continue contributing real engineering knowledge and reliable battery manufacturing solutions to support global partners in medical, industrial, wearable, and consumer electronics sectors.

-

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More -

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More -

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More -

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More -

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More