A lithium cell is the fundamental energy storage unit powering modern electronic devices, electric vehicles, energy storage systems, and industrial equipment. Understanding lithium cell technology is essential for engineers, procurement managers, and system integrators seeking reliable and efficient power solutions.

What Is a Lithium Cell?

A lithium cell is the fundamental electrochemical unit used to store and release electrical energy in modern rechargeable and non-rechargeable battery systems. Unlike a complete battery pack, which integrates multiple components, a lithium cell represents the core energy storage element.

Lithium cells are widely used because of their:

-

High energy density

-

Stable voltage output

-

Lightweight structure

-

Long service life

Today, lithium cells power everything from medical devices and consumer electronics to electric vehicles, energy storage systems, and industrial equipment.

Why Lithium Cells Dominate Modern Energy Storage

Lithium has the highest electrochemical potential among commercial battery materials, making it ideal for high-performance energy storage.

Key Advantages of Lithium Cells

-

Energy density up to 250–300 Wh/kg

-

Low self-discharge rate

-

High round-trip efficiency (>95%)

-

Flexible form factors

-

Scalable for small and large systems

According to the U.S. Department of Energy, lithium-ion technology remains the most commercially viable battery chemistry for scalable electrification systems.

Main Types of Lithium Cells

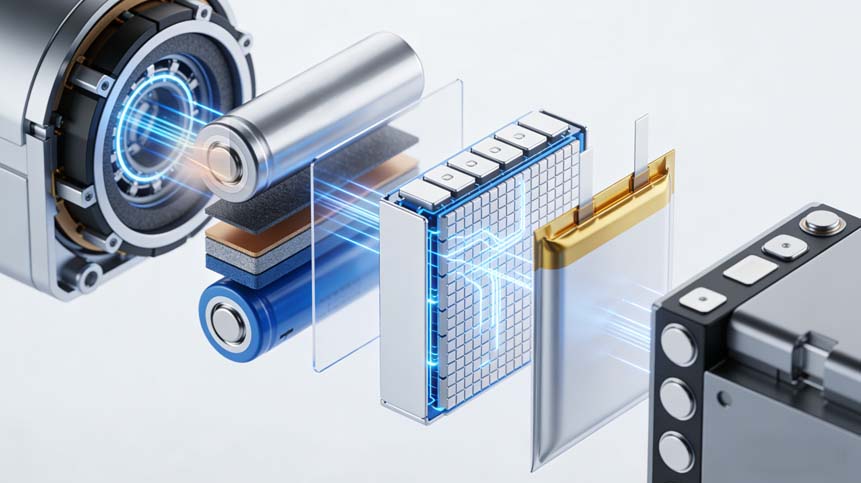

Lithium cells are classified by form factor and electrochemical chemistry.

Lithium Cell Form Factors Explained

Cylindrical Lithium Cells (18650, 21700, 4680)

Cylindrical cells are widely adopted due to mature manufacturing and consistent quality.

| Cell Type | Diameter | Height | Typical Capacity |

|---|---|---|---|

| 18650 | 18 mm | 65 mm | 2.0–3.5 Ah |

| 21700 | 21 mm | 70 mm | 4.0–5.0 Ah |

| 4680 | 46 mm | 80 mm | 20+ Ah |

Advantages

-

Excellent thermal stability

-

High mechanical strength

-

Easy automation

Prismatic Lithium Cells

Prismatic cells use rectangular aluminum housings and are common in EVs and ESS systems.

Advantages

-

High space utilization

-

Fewer cells per pack

-

Simplified module design

Trade-offs

-

Higher cost

-

More complex thermal management

Lithium Polymer (LiPo) Cells

LiPo cells use pouch packaging and are popular in compact electronics.

Advantages

-

Ultra-thin design

-

Flexible shapes

-

Lightweight

Limitations

-

Lower mechanical protection

-

Higher sensitivity to swelling

Lithium Cell Chemistry Types

NMC (Nickel Manganese Cobalt)

-

Balanced energy and power

-

Widely used in EVs and ESS

-

Good cycle life (1000–2000 cycles)

NCA (Nickel Cobalt Aluminum)

-

High energy density

-

Common in high-performance EVs

-

Requires strict thermal control

LFP (Lithium Iron Phosphate)

-

Excellent safety

-

Long cycle life (3000–6000 cycles)

-

Lower energy density

LCO and LMO (Specialty Uses)

-

Consumer electronics

-

Power tools

-

Shorter cycle life

Lithium Cell Performance Metrics (Data-Supported)

Key Technical Parameters

| Parameter | Typical Range |

|---|---|

| Nominal Voltage | 3.2–3.7V |

| Energy Density | 150–300 Wh/kg |

| Cycle Life | 800–6000 cycles |

| Charge Efficiency | >99% |

| Self-Discharge | <3% per month |

Data source references:

Lithium Cell Manufacturing Process

Core Manufacturing Steps

-

Electrode slurry mixing

-

Coating and calendaring

-

Cell stacking or winding

-

Electrolyte filling

-

Formation and aging

-

Capacity grading and matching

Cell consistency directly determines battery pack safety, lifespan, and reliability.

Cell Matching and Consistency (Critical for Pack Design)

Lithium cells used in battery packs must meet strict matching criteria:

-

Capacity deviation ≤2%

-

Internal resistance deviation ≤3%

-

Voltage deviation ≤10mV

Poor matching accelerates degradation and increases safety risk.

Safety Standards and Certifications for Lithium Cells

Mandatory Certifications

Applications of Lithium Cells

Consumer Electronics

-

Smartphones

-

Laptops

-

Wearables

Medical Devices

-

Infusion pumps

-

Portable monitors

-

Diagnostic equipment

Electric Mobility

-

E-bikes

-

Scooters

-

Electric motorcycles

Energy Storage Systems (ESS)

-

Residential solar storage

-

Commercial backup power

-

Off-grid systems

Industrial Equipment

-

AGVs

-

Robotics

-

Portable tools

Lithium Cell vs Battery Pack

| Lithium Cell | Lithium Battery Pack |

|

|

|

|

This distinction is critical for procurement and system design.

How to Choose the Right Lithium Cell

Key Selection Factors

-

Required voltage and capacity

-

Power demand (C-rate)

-

Operating temperature

-

Cycle life expectations

-

Safety and certification requirements

Custom Lithium Cell Solutions for B2B Projects

In many industries, off-the-shelf lithium cells are insufficient.

Customization may include:

-

Cell grading and matching

-

Chemistry optimization

-

Special testing protocols

-

Long-term supply consistency

Manufacturers with in-house engineering and quality control provide higher reliability for B2B applications.

Frequently Asked Questions (FAQ)

What is the difference between a lithium cell and a lithium battery?

A lithium cell is a single energy unit, while a lithium battery consists of multiple cells plus protection and management systems.

Which lithium cell type is best?

There is no universal best cell. The optimal choice depends on application requirements such as energy density, safety, and cycle life.

Are lithium cells safe?

Yes, when manufactured to international standards and used within specified limits, lithium cells are safe and reliable.

How long do lithium cells last?

Depending on chemistry and usage, lithium cells typically last 3–15 years or 800–6000 cycles.

Can lithium cells be customized?

Yes. Cell matching, chemistry selection, and testing protocols can be customized for professional applications.

Conclusion

Lithium cells are the foundation of modern electrification. Understanding their types, performance characteristics, safety standards, and application scenarios is essential for engineers, buyers, and system integrators.

For businesses requiring stable supply, consistent quality, and long-term reliability, working with an experienced lithium cell and battery manufacturer ensures performance, safety, and compliance across global markets.