Lithium Ion Battery Cell: A Practical Data-Driven Guide

I wrote this article to be the one place you — an engineer, procurement manager, or product designer — can turn to for a structured, trustworthy explanation of lithium ion battery cells: what they are, how they differ by form factor and chemistry, how they age, what standards matter in shipping and certification, and how I recommend selecting the right cells for projects. I’ll cite authoritative sources and give you data tables you can copy into proposals.

Quick Summary and Direct Answer

If you only need a short answer: a lithium ion battery cell is a single electrochemical unit (commonly 3.6–3.7 V nominal) that stores energy using reversible lithium-ion intercalation. Cells come in standard sizes (18650, 21700, 4680, pouch, prismatic) and differ mainly in capacity, energy density, power capability, and manufacturability. For shipping and market acceptance you should verify IEC 62133 certification and UN38.3 test compliance.

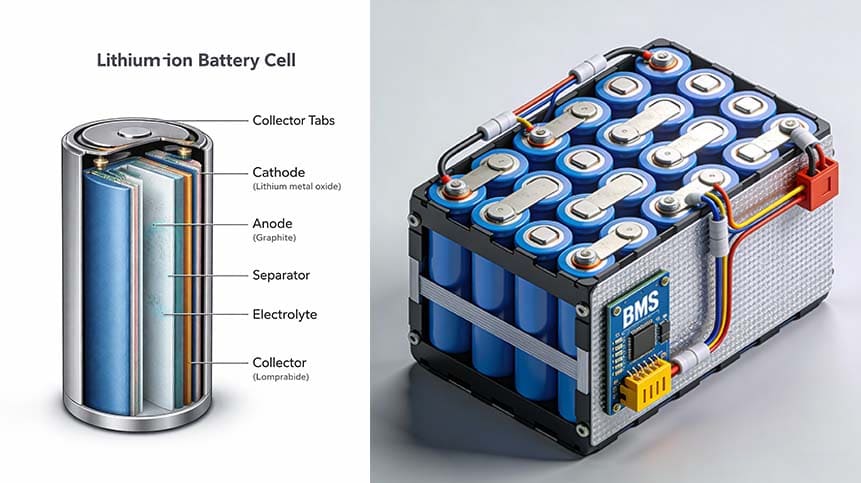

What is a Lithium Ion Battery Cell?

I define a lithium ion battery cell as a sealed electrochemical device that converts chemical energy to electrical energy through lithium-ion migration between electrodes. A single cell typically has a nominal voltage determined by its chemistry (about 3.6–3.7 V for traditional Li-ion chemistries). Multiple cells assembled together make a battery pack with higher voltage or capacity.

Cell vs. Battery Pack

-

Cell: single electrochemical element (e.g., one 18650 cylinder).

-

Module / Pack: engineered assembly of cells + BMS (battery management system), mechanical structure, thermal management, fuses, and connectors.

I always treat cells as the fundamental buying unit; pack design depends on the chosen cell’s shape, thermal characteristics and recommended thermal management procedures. (See Testing & Aging section for why cell-level validation matters.)

How a Li-ion Cell Works

At a high level: during charge lithium ions move from cathode to anode through the electrolyte and separator; on discharge they move back, generating current through the external circuit. Key internal components:

-

Cathode (positive): e.g., NMC, NCA, LFP — largely dictates energy density and safety behavior.

-

Anode (negative): typically graphite (or silicon-graphite blends).

-

Electrolyte: liquid organic solvent with lithium salt (e.g., LiPF6) or increasingly quasi-solid/solid systems in advanced cells.

-

Separator: porous polymer that prevents electronic contact while allowing ions to pass.

Main Chemistries and Trade-offs

I think of chemistries as a three-way trade-off: energy density, power & cycle life, safety/cost.

-

NMC / NCA: higher energy density, good for EVs and portable electronics, but cost & thermal risk higher.

-

LFP (Lithium Iron Phosphate): lower energy density, excellent safety & cycle life — often preferred in energy storage and some EV markets.

-

LTO (Lithium Titanate): low energy but very long life and fast charge capability (specialty markets).

Common Cell Formats and Specifications

Cell format matters for mechanical packaging, thermal behavior and cost. The big families are cylindrical, prismatic (metal case), and pouch (flexible laminate).

Cylindrical: 18650, 21700, 4680

Cylindrical cells are widely used in consumer electronics and EVs because they are robust mechanically and mature for high-volume manufacturing. Typical nominal voltages are ~3.6–3.7 V depending on chemistry.

I pulled up comparative industry references to put realistic spec ranges together. The figures below reflect typical published ranges for widely used cells.

Data table — comparative cell specs

| Cell type | Diameter × Length (mm) | Nominal Voltage (V) | Typical Capacity (mAh) | Typical Energy Density (Wh/kg) | Typical Use |

|---|---|---|---|---|---|

| 18650 | 18 × 65 | 3.6–3.7 | 2,300–3,600 | ~150–245 (cell-level varies by chemistry) | Laptops, power tools, legacy EV modules. |

| 21700 | 21 × 70 | 3.6–3.7 | 3,000–5,000 | similar or slightly higher than 18650 | Newer EV packs, high-energy power banks. |

| 4680 | 46 × 80 | 46 × 80 | 5,000–8,000 (manufacturer estimates vary) | higher cell-level energy possible due to format | Large-format EV ambitions (Tesla, others) but manufacturing maturity varies. |

| Pouch (various) | Custom | 3.6–3.7 | 50 mAh — 10000+ mAh | Wide range depending on stack/chemistry | Smartphones, wearables, custom battery packs. |

| Prismatic (metal) | Custom | 3.6–3.7 | 1,000 mAh — 10000+ mAh | Good volumetric efficiency for packs | Automotive & industrial modules. |

Notes: energy density ranges are chemistry-dependent (NMC/NCA higher, LFP lower). Battery University and manufacturer spec sheets are good sources for exact cell-level Wh/kg for a specific cell model.

Performance: Energy Density, Power and Cycle Life

I always separate energy density (Wh/kg or Wh/L) from power capability (W/kg) because they often trade off. Typical commercial Li-ion energy density has gradually improved; mainstream cells commonly range from ~150 Wh/kg to over 250 Wh/kg at the cell level depending on chemistry and manufacturer. Advanced research and specialty cells can exceed these numbers, but manufacturing cost and safety trade-offs apply.

Cycle life and calendar ageing

A conservative design assumption for many consumer/industrial Li-ion chemistries is 300–1000 full cycles before noticeable capacity degradation (often 70–80% of original capacity at end-of-life depending on chemistry and depth-of-discharge). LFP often exhibits higher cycle life (1,000+ cycles) at the cost of lower energy density. I recommend you always ask suppliers for validated cycle-life test data under your intended charge/discharge profile.

Safety, Standards and Shipping

Safety and compliance are non-negotiable. Two standards are essential for commercial circulation:

IEC 62133

IEC 62133 is the baseline global safety standard for portable sealed secondary lithium cells and batteries. It specifies a set of abuse tests (short circuit, mechanical shock, thermal tests, etc.) to demonstrate safe behavior under normal and certain misuse conditions. For many markets, IEC 62133 certification (often via an accredited test lab such as TÜV, Intertek, or UL) is required or expected.

UN 38.3 (transport/shipping)

UN 38.3 comprises transport tests required to ship lithium batteries internationally. Tests simulate altitude, thermal, vibration, shock, external short circuit, impact/overcharge and more. Since January 1, 2008, shippers must provide a lithium battery test summary demonstrating UN 38.3 compliance; air cargo rules are particularly strict (e.g., SOC limits for air). For cargo air shipment, cells are typically required to be at or below 30% state-of-charge (SOC) per common guidance. I recommend always asking suppliers for UN 38.3 test summaries when planning cross-border logistics.

Manufacturing Quality & Inspection

When sourcing cells, I insist on the following supplier capabilities and documentation:

-

Traceable cell lot numbers and date codes.

-

Material certificates for cathode/anode/raw materials.

-

Cell-level test reports: capacity distribution, internal resistance (IR), visual inspection, leak/pressure test, formation profile, cycle test sample results.

-

Certifications: IEC 62133, CE (where applicable), and UN 38.3 test summary for shipping.

A factory audit (on-site or 3rd-party) should verify process controls: dry rooms, formation/aging lines, environmental controls and cleanliness and waste-handling practices.

Aging, Testing and Quality Controls

Aging behavior depends on usage patterns (depth-of-discharge, C-rates, temperature) and storage conditions (SOC, temperature). I run or request a test matrix including:

-

Formation & initial capacity measurement (batch-level).

-

Aging test: calendar aging at elevated temp and SOC states to model storage degradation.

-

Cycle life test: typical cycles at intended C-rates and depth-of-discharge.

-

Safety/abuse tests: nail penetration, overcharge, thermal ramp, etc. (often performed for certification).

Manufacturer-provided test data should specify test conditions: temperature, C-rate, DoD, acceptance criteria. Practical guidance and background on how to prolong Li-ion life is summarized by industry references.

Choosing Lithium Ion Battery Cells for Your Product

Requirements definition

-

Define energy needs (Wh), peak power (W), voltage, expected cycle life, and operating temperatures.

-

Decide physical constraints (volume/weight/shape).

-

Define certification/regulatory needs for target markets (medical devices, aviation, automotive require stricter standards).

Supplier & technical checks

-

Verify IEC 62133 certificate and UN 38.3 test summary.

-

Request sample cells and run your own qualification tests (capacity, IR, cycle test under your BMS profile).

-

Ask for process & QC documentation: formation recipe, aging protocols, cell sorting/selection criteria.

-

Confirm warranty and failure-rate terms for volume purchases.

I always insist on validating a small pilot run and performing field tests under my real-world load and temperature profiles before scaling.

Data-driven selection: example decision

If you're building a handheld medical device that must last 8–10 hours and tolerate hospital disinfection temperatures, you might choose a high-reliability pouch cell from a reputable maker with IEC 62133 and documented cycle life at the device’s expected charge/discharge profile. If you're building a high-energy e-bike, 21700 or prismatic cells with high Wh/kg may be a better choice. For grid storage where safety and long life rank higher than energy density, LFP prismatic cells are often selected.

References

-

Battery University — “Basics of Li-ion cells & energy density.”

-

UN/PHMSA Lithium Battery Guide — “Transport and UN 38.3 guidance.”

-

TÜV SÜD or Intertek pages on battery testing — “Third-party testing & certification services.”

Frequently Asked Questions

Q1: What is the nominal voltage of a lithium ion battery cell?

A: Most common Li-ion chemistries use a nominal cell voltage around 3.6–3.7 V. Specific chemistries or designs may use slightly different nominal values (e.g., LTO ~2.4–2.8 V).

Q2: How do I know a cell is safe to buy for my product?

A: Ask for IEC 62133 test reports/certificates and the UN 38.3 test summary if you will ship internationally. Request sample cells and run your own acceptance tests (capacity, IR, cycle, abuse where appropriate).

Q3: What lifetime can I expect from a typical Li-ion cell?

A: Typical consumer Li-ion cells are often specified for ~300–500 full cycles to 80% capacity under manufacturer test conditions; premium chemistries and conservative depth-of-discharge profiles can reach 1,000+ cycles (especially for LFP). Always evaluate using your real duty cycle.

Q4: How should I store cells for best shelf life?

A: Store at cool temperatures (but above freezing if recommended), at ~30–50% SOC for long-term storage, and in a dry, controlled environment. Elevated temperatures accelerate calendar aging.

Q5: What do 18650, 21700, 4680 mean?

A: These are cylindrical format codes — the first two digits are diameter (mm), the next three digits are length (mm). Example: 18650 = 18 mm × 65 mm. Larger formats generally allow higher capacity per cell but require manufacturing adaptation.

Practical procurement checklist for an RFQ

When you request quotes, include:

-

Required cell format and chemistry.

-

Targeted Wh, voltage, and peak power (W).

-

Required certifications (IEC 62133, UN 38.3, any medical device ISO).

-

Expected operating temperature range and mechanical shock/vibration conditions.

-

Expected lifetime (cycles) and warranty expectations.

-

Any required labeling, customs or shipping constraints.

If you send this checklist to suppliers, you’ll get much more comparable and actionable quotes.

Example micro-case

I once qualified a pouch cell supplier for a medical monitor: the supplier provided IEC 62133 and UN 38.3 summaries, production lot testing, and agreed to a 6-month pilot lot with formation/aging certificates. After a 3-month field pilot at 25°C with normal charge cycles, capacity fade matched the supplier’s projections and we scaled. The key takeaway: insist on pilot lots + independent test samples and detailed formation recipes so you can reproduce the performance later.

Concluding recommendations

-

Treat cells as engineered components: validate with real-world tests (pilot production).

-

Require IEC 62133 & UN 38.3 documentation for most commercial flows.

-

Use the data table above to shortlist cell formats consistent with space/weight/energy requirements.

-

Publish test summaries and case studies on your site to build EEAT and help buyers choose you

Conclusion and Next Steps

Need Lithium Ion Battery Cells for Your Project?

At A&S Power, we support OEMs with certified lithium ion battery cells (IEC 62133 / UN38.3) and documented performance data.

-

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More -

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More -

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More -

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More -

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More