Lithium LiPo Battery for Emergency and Special Equipment

Introduction: Why Power Reliability Matters in Emergency Equipment

When we design or specify emergency and special equipment, power reliability is not a feature—it is a requirement. From portable high-intensity flashlights used by rescue teams to emergency exit signage in public buildings, these devices are expected to operate instantly, predictably, and safely under stressful conditions.

As a battery manufacturer working closely with OEMs and system integrators, we see a clear trend: lithium polymer (LiPo) batteries are increasingly replacing older NiMH and lead-acid solutions in compact emergency tools. This shift is driven by higher energy density, flexible form factors, and fast charging capabilities that align with modern USB-C power ecosystems.

In this guide, I’ll walk through how LiPo batteries are used in emergency and special equipment, what specifications actually matter, and how to select or customize the right battery pack for your application—based on real-world engineering and product design considerations.

Typical Use Cases for LiPo Batteries in Emergency and Special Equipment

Portable Emergency Lighting

Portable lighting remains one of the largest application segments for LiPo batteries in emergency equipment.

Common products include:

-

High-intensity handheld torches

-

Rechargeable camping lamps

-

Emergency lanterns for vehicles and homes

-

Tactical or rescue flashlights with strobe modes

These devices typically demand:

-

High peak discharge for LED output

-

Stable voltage to prevent brightness drop

-

Fast recharge to minimize downtime

Modern emergency lights increasingly integrate USB-C charging, making LiPo cells in the 1000–5000 mAh range ideal for balancing runtime and recharge speed.

Small Solar Energy Storage Units (Street Lamp Nodes)

In smart or decentralized infrastructure, LiPo batteries are now widely used in small solar-powered systems, such as:

-

Solar street lamp nodes

-

Emergency pathway lighting

-

Temporary warning lights

Here, LiPo batteries function as short-term energy storage, charged during daylight and discharged at night or during power failures.

Key requirements include:

-

Good cycle life under partial charge conditions

-

Wide operating temperature tolerance

-

Compatibility with compact solar charge controllers

Compared to cylindrical Li-ion cells, flat LiPo pouch cells simplify enclosure design and reduce overall system volume.

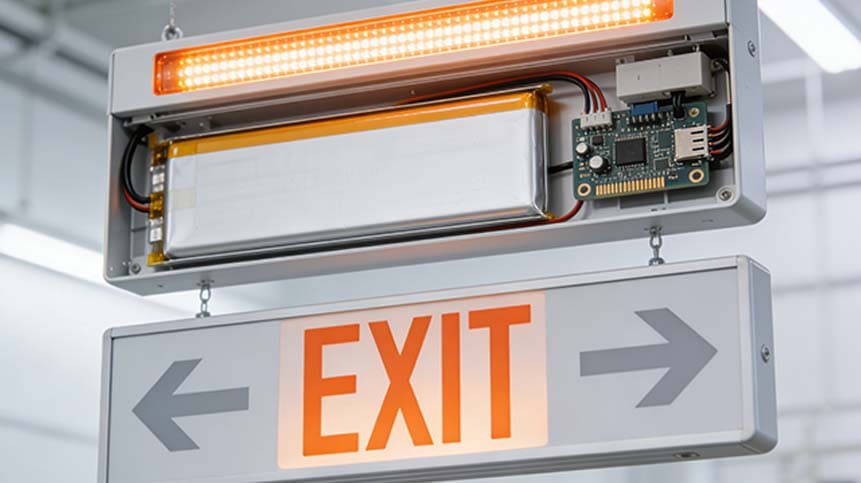

Emergency Signage and Exit Indicators

Emergency signage—exit signs, evacuation route indicators, and safety markers—often operates in standby mode for long periods and must activate instantly during outages.

LiPo batteries are suitable because they offer:

-

Low self-discharge

-

Compact size for slim signage housings

-

Predictable discharge curves

Typical capacities range from 2000–6000 mAh, depending on LED count and required emergency illumination duration (often 90–180 minutes per safety regulations).

Escape and Personal Emergency Equipment

Personal escape equipment includes:

-

Emergency breathing apparatus indicators

-

Wearable distress beacons

-

Compact rescue tools

In these products, weight, size, and safety are critical. LiPo batteries allow designers to:

-

Fit power sources into curved or irregular housings

-

Reduce total device mass

-

Maintain sufficient energy for short but critical usage windows

Why Lithium Polymer Batteries Are Well-Suited for Emergency Equipment

High Energy Density in Compact Volumes

LiPo batteries typically offer 150–250 Wh/kg, allowing emergency devices to remain portable without sacrificing runtime. For handheld lighting and signage, this translates to longer operation without increasing enclosure size.

Fast Recharge with Modern USB-C Charging

One major advantage of LiPo batteries in emergency tools is rapid recharge capability when paired with modern charging interfaces.

Many current designs support:

-

USB-C input

-

Power Delivery (PD) protocols

-

Multi-port charging compatibility

For example:

-

A 3000 mAh LiPo pack can often recharge in 1–1.5 hours using a 15–20 W PD charger.

-

A 5000 mAh pack may recharge in 1.5–2.5 hours, depending on internal PCM limits.

It’s important to note that actual charging time depends on:

-

Cell chemistry and internal resistance

-

PCM (Protection Circuit Module) current limits

-

Thermal management design

-

Charger power rating

This mirrors real-world power bank designs, where safety constraints intentionally limit peak charge current.

Flexible Form Factor for Product Integration

Unlike rigid cylindrical cells, LiPo batteries can be:

-

Ultra-thin (4–6 mm for wearable or signage use)

-

Custom-shaped to fit enclosures

-

Stacked or layered for modular designs

This flexibility is especially valuable in emergency signage and compact lighting, where industrial design constraints are tight.

Safety and Protection Compatibility

When properly designed, LiPo battery packs integrate well with:

-

Over-charge protection

-

Over-discharge protection

-

Over-current and short-circuit protection

-

Temperature monitoring (NTC)

For emergency equipment, this ensures long-term standby safety, even when devices remain plugged in or unused for extended periods.

Typical Specifications and Selection Guidelines

Capacity Selection (mAh)

Capacity depends on:

-

LED wattage

-

Required runtime

-

Standby power consumption

Typical ranges:

| Application Type | Common Capacity Range |

|---|---|

| Handheld emergency torch | 1000–3000 mAh |

| Camping lantern | 3000–6000 mAh |

| Emergency signage | 2000–8000 mAh |

| Solar street light node | 4000–10,000 mAh |

Charge Method Considerations

USB-C charging has become a key product differentiator in emergency equipment.

Design considerations include:

-

Single-cell (3.7V) vs multi-cell configurations

-

PD trigger module integration

-

Charge current derating for thermal safety

For many compact emergency tools, single-cell LiPo with boost regulation offers the best balance of simplicity and safety.

Thermal Management and High-Output LEDs

High-output LEDs generate heat that can affect battery performance.

Best practices include:

-

Physical separation between LED and battery

-

Aluminum heat sinks for LEDs

-

Conservative discharge current limits

Ignoring thermal design can reduce cycle life and compromise safety, especially in sealed lanterns.

Safety, Compliance, and Certification Considerations

Emergency equipment batteries often require compliance with:

-

UN38.3 (transport safety)

-

IEC 62133 (rechargeable battery safety)

-

CE / UKCA for finished products

For signage and public-use equipment, additional regional safety standards may apply.

From an OEM perspective, choosing a battery supplier that provides complete test documentation is critical for smooth product certification.

How Custom LiPo Battery Packs Improve Emergency Equipment Performance

Off-the-shelf batteries rarely fit emergency equipment perfectly.

Custom LiPo solutions allow:

-

Tailored capacity and discharge rates

-

Optimized PCM design for standby safety

-

Connector and cable customization

-

Mechanical fit optimization

This is especially important for B2B emergency equipment manufacturers, where reliability and compliance directly affect product liability.

Data-Backed Comparison: LiPo vs Alternative Battery Types

| Battery Type | Energy Density | Form Factor Flexibility | Recharge Speed | Suitability for Emergency Gear |

|---|---|---|---|---|

| LiPo | High | Excellent | Fast | ★★★★★ |

| Li-ion (cylindrical) | High | Limited | Medium | ★★★★☆ |

| NiMH | Medium | Limited | Slow | ★★☆☆☆ |

| Lead-acid | Low | Very limited | Slow | ★☆☆☆☆ |

References

Frequently Asked Questions (FAQ)

How long can a LiPo battery power emergency lighting?

Runtime depends on LED wattage and battery capacity. A 3000 mAh LiPo battery can typically power a 3–5 W emergency light for 2–4 hours.

Are LiPo batteries safe for emergency signage that stays plugged in?

Yes, when designed with proper PCM and thermal management. Continuous float charging should be avoided; instead, controlled charge cycles are recommended.

Can LiPo batteries work with solar charging systems?

Absolutely. LiPo batteries are widely used in small solar storage units, provided the charge controller is designed for lithium chemistry.

What is the typical lifespan of a LiPo battery in emergency equipment?

Most LiPo batteries offer 300–500 full cycles, which translates to several years of service in standby-oriented emergency applications.

Conclusion: Designing Reliable Emergency Equipment Starts with the Right Battery

Lithium polymer batteries have become a core enabling technology for modern emergency and special equipment. Their combination of compact size, fast charging, and flexible integration allows manufacturers to build safer, lighter, and more responsive products.

From portable lighting to emergency signage and solar-powered nodes, selecting the right LiPo battery—and designing it correctly—directly impacts product reliability and user safety.

If your emergency equipment requires custom battery solutions, consistent quality, and full compliance support, working with an experienced LiPo battery manufacturer is not just an advantage—it’s a necessity.

Related articles:

3.7V LiPo Battery Applications: an industry guide

Lithium LiPo Battery for Portable Consumer Electronic Devices

Lithium LiPo Battery for Beauty Products (K-Beauty & Beyond)

Lithium LiPo Battery for Electric Toys and Models (Drones, RC)

3.7V Lithium Battery Customization: A Complete OEM & Engineering Guide

Custom LiPo Battery: OEM Lithium Polymer Battery Solutions Built for Your Product

-

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More -

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More -

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More -

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More -

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More