Silicon-carbon (Si-C) batteries have rapidly emerged as one of the most promising next-generation battery technologies, offering significantly higher energy density, faster charging capabilities, and improved low-temperature performance compared with conventional lithium-ion (Li-ion) batteries. While standard Li-ion batteries have relied primarily on graphite anodes for more than 30 years, the industry is approaching the theoretical limits of graphite. Silicon-carbon composite anodes are widely recognized as the most realistic commercial upgrade before full silicon anodes or solid-state batteries become mainstream.

This professional report provides a complete, engineering-level comparison between silicon-carbon batteries and traditional lithium-ion batteries. It includes chemical differences, energy density metrics, cycle life considerations, stress-strain mechanics, cost curves, charging characteristics, thermal management requirements, and real engineering applications across consumer electronics, EVs, medical devices, wearables, and industrial markets.

1. Overview of Silicon-Carbon vs Lithium-Ion Battery Technologies

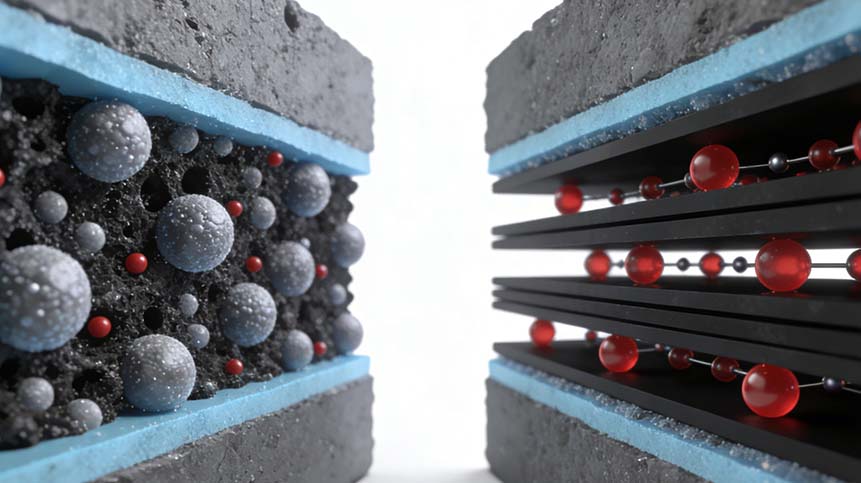

| To understand the advantages of silicon-carbon batteries, it is essential to examine the core structural differences in anode materials. Traditional Li-ion chemistry uses graphite (C₆) as the dominant anode. Silicon-carbon batteries use a composite of silicon (Si) and carbon (C), typically engineered with nano-structured silicon particles embedded in a carbon matrix. This structure helps reduce silicon’s well-known expansion problem during lithiation. |  |

1.1 Chemical Structure Comparison

| Feature | Silicon-Carbon Anode | Graphite Anode (Li-ion) |

|---|---|---|

| Theoretical capacity (mAh/g) | 2,000–3,600 | 300–372 |

| Volume expansion during lithiation | Up to 300% | ~10% |

| Conductivity | Moderate (improved with carbon) | High |

| Mechanical stability | Requires engineered composites | Stable |

| Commercial maturity | Growing | Highly mature |

These foundational material differences drive nearly every performance distinction observed in real-world battery packs.

2. Energy Density Comparison: Gravimetric and Volumetric

Energy density is the most frequently cited advantage of silicon-carbon batteries. Because the anode is no longer the limiting factor in cell capacity, the industry sees increases in both gravimetric (Wh/kg) and volumetric (Wh/L) energy density.

2.1 Typical Commercial Energy Density Values

| Battery Type | Gravimetric (Wh/kg) | Volumetric (Wh/L) |

|---|---|---|

| Lithium-ion (standard graphite) | 180–260 | 500–730 |

| Silicon-carbon enhanced Li-ion | 260–350 | 700–950 |

Real production values vary based on NCM, NCA, LFP, or blended cathode materials, but silicon-carbon universally provides measurable gains.

3. Charging Speed and Fast-Charging Behavior

One of the strongest performance benefits of silicon-carbon batteries is rapid lithium diffusion and lower charge-transfer resistance, enabling higher C-rates and shorter charging times.

3.1 Charging Speed Comparison

| Battery Type | Recommended Fast Charge Rate | Time to 80% |

|---|---|---|

| Lithium-ion | 0.8C–1C | 45–60 minutes |

| Silicon-carbon | 1.2C–2C | 20–35 minutes |

These improvements stem from:

- Silicon’s higher lithium diffusion rate

- Reduced polarization during high-current charging

- Enhanced SEI (solid-electrolyte interphase) stability with engineered coatings

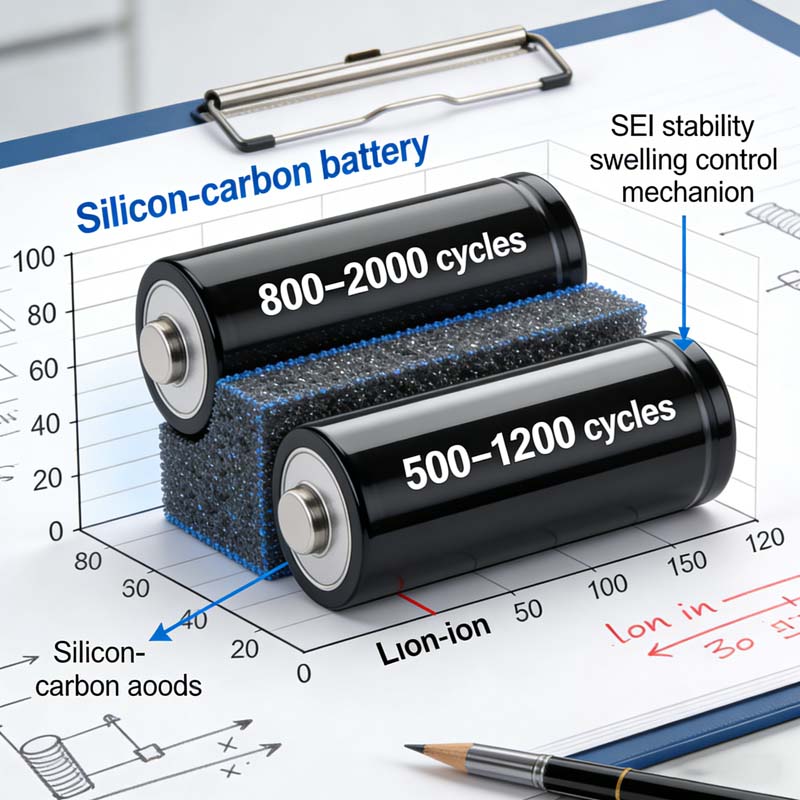

4. Cycle Life and Degradation Mechanisms

Historically, silicon-based anodes suffered from rapid degradation due to expansion and contraction during cycling. Modern silicon-carbon composites significantly improve mechanical stability.

4.1 Cycle Life Comparison

| Battery Type | Typical Cycle Life (80% retention) |

|---|---|

| Lithium-ion (graphite) | 500–1,200 cycles |

| Silicon-carbon | 800–2,000 cycles |

These results depend on silicon content. Low-silicon blends (~5%) improve longevity without sacrificing stability, while high-silicon blends (~15–30%) offer higher capacity but may reduce cycle life unless paired with advanced SEI stabilization techniques.

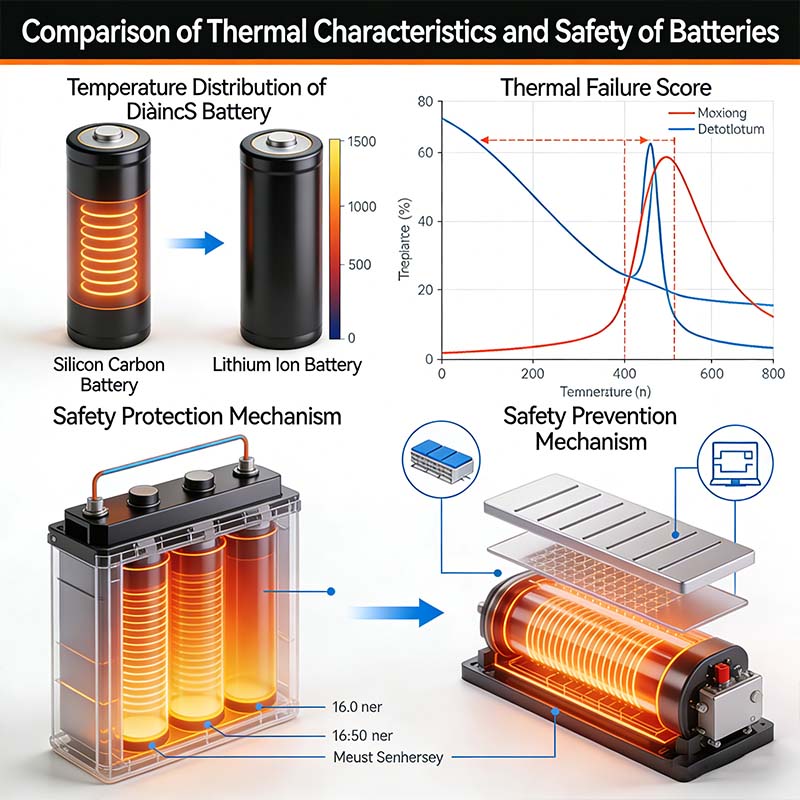

5. Thermal Characteristics and Safety Performance

Both battery types use similar electrolyte systems, but silicon-carbon batteries often show improved thermal performance due to lower internal resistance and reduced heat generation during high-current operation.

5.1 Thermal Runaway Thresholds

| Battery Type | Thermal Runaway Onset | Notes |

|---|---|---|

| Lithium-ion | 180–210°C | Stable but sensitive to overcharge |

| Silicon-carbon | 190–230°C | Improved stability due to reduced overpotential |

Safety depends heavily on pack design, BMS sophistication, and cathode chemistry (NMC vs LFP vs NCA).

6. Applications Comparison

Silicon-carbon batteries are increasingly used in performance-critical applications, while lithium-ion remains dominant in cost-sensitive or established markets.

6.1 Application Suitability Table

| Application | Graphite Li-ion | Silicon-Carbon |

|---|---|---|

| Smartphones | Good | Excellent |

| Wearables | Good | Excellent |

| Electric Vehicles | Common | Growing fast |

| Medical Devices | Reliable | High performance |

| Industrial | Stable | Improving |

7. Cost Analysis and Commercial Scalability

Silicon-carbon cells are more expensive due to:

- Specialized coating processes

- Nano-composite engineering

- Higher-precision slurry mixing

- SEI stabilization materials

7.1 Cost Range Comparison

| Type | Cost per Wh |

|---|---|

| Lithium-ion | $0.09–$0.14 |

| Silicon-carbon | $0.12–$0.20 |

However, cost is expected to decline by 20–30% within the next five years as production volume increases.

8. Engineering Challenges

Key engineering challenges for silicon-carbon batteries include:

- Volume expansion management

- SEI durability improvement

- Mechanical integrity during cycling

- Cost-effective large-scale manufacturing

9. FAQs

1. Are silicon-carbon batteries safer than lithium-ion batteries?

Generally yes, due to lower internal resistance and improved heat management.

2. Do silicon-carbon batteries charge faster?

Yes, commonly reaching 80% in 20–35 minutes depending on the C-rate.

3. Will silicon-carbon batteries replace lithium-ion?

Not entirely; they will coexist. Silicon-carbon will dominate high-performance applications.

4. What industries adopt silicon-carbon first?

EVs, premium smartphones, medical devices, drones, wearables.

5. Do silicon-carbon batteries require different BMS?

Not majorly, but fast-charging profiles may require optimized algorithms.

6. What is the real commercial silicon percentage?

5–15% silicon is common in commercial cells.

7. Are silicon-carbon batteries compatible with NMC or LFP?

Yes, compatible with both; often paired with NMC for EVs.

8. Do silicon-carbon batteries swell?

Well-designed composites reduce swelling dramatically.

9. What temperature range improves most?

Low-temperature discharge shows significant improvement.

10. How much energy density improvement is typical?

10–25% depending on silicon content.

10. Conclusion

Silicon-carbon batteries represent a major step forward in lithium-ion technology. They deliver higher energy density, faster charging, better low-temperature performance, and increasingly competitive cycle life. While costs remain slightly higher than standard graphite-based Li-ion cells, rapid industry adoption—especially in EVs, premium electronics, and medical devices—indicates strong long-term commercial scaling.

For brands, OEM manufacturers, and engineering teams aiming to deliver higher efficiency and more compact battery systems, silicon-carbon batteries provide a practical, commercially available upgrade over traditional lithium-ion cells without requiring a complete ecosystem overhaul.