Summarize of polymer lithium-ion polymer batteries

Summary of Polymer Lithium-Ion Batteries: The Flexible Power Solution for Modern Applications

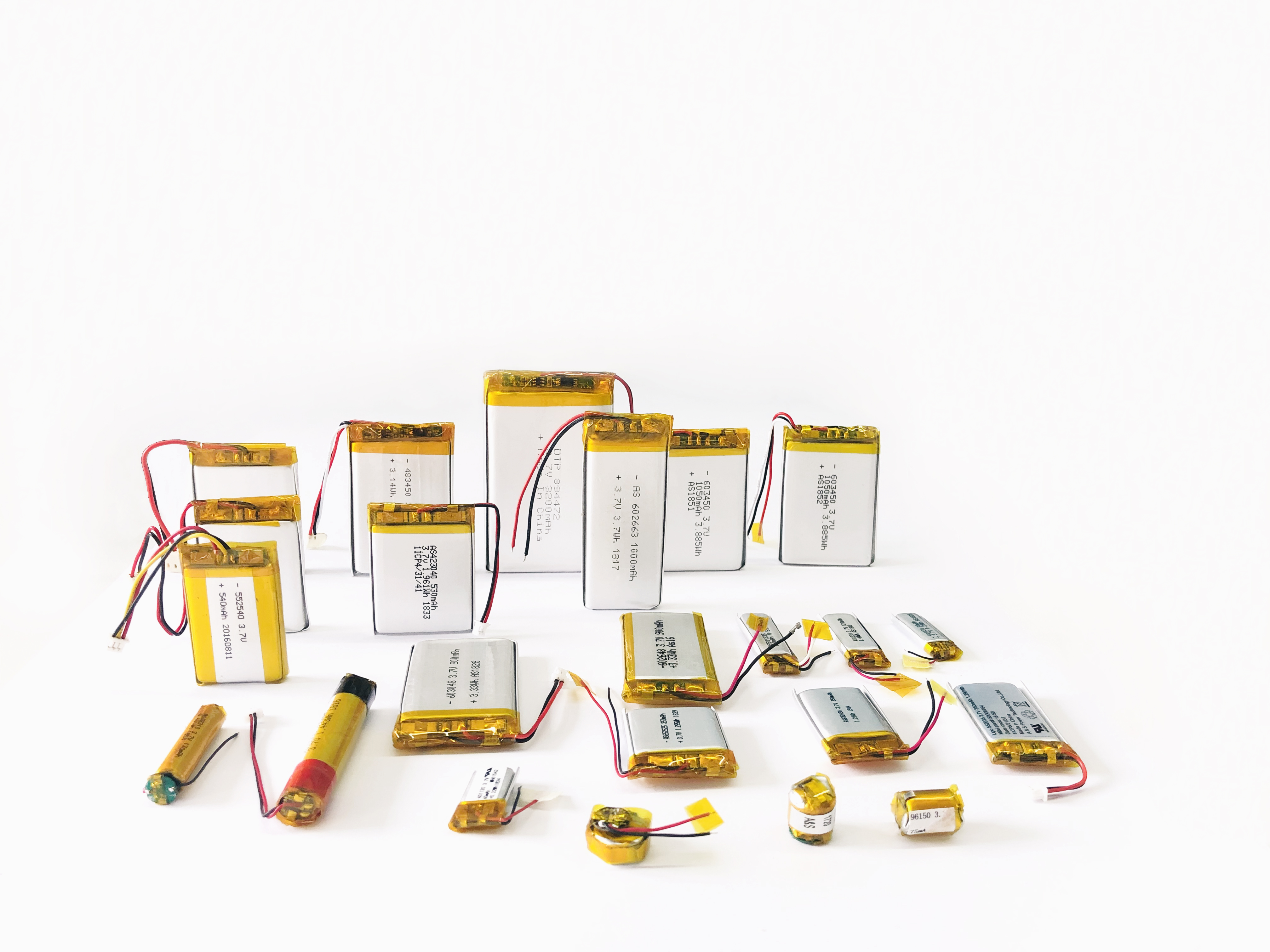

Polymer lithium-ion (LiPo) batteries have emerged as a cornerstone of portable power solutions, combining high energy density with exceptional design flexibility. As the global market for flexible batteries approaches $15 billion by 2025, understanding their unique characteristics, applications, and technological advancements becomes crucial for manufacturers, distributors, and end-users. This comprehensive analysis examines the key aspects of LiPo battery technology, market trends, and future developments that are shaping industries from consumer electronics to electric vehicles.

Core Characteristics of Polymer Lithium-Ion Batteries

1. Structural Advantages Over Conventional Designs

LiPo batteries distinguish themselves through their unique polymer electrolyte composition:

- Flexible Packaging: Enables ultra-thin designs down to 0.4mm thickness

- No Metal Casing: 20-30% weight reduction compared to cylindrical cells

- Custom Shapes: Adaptable to product-specific form factors

- Higher Energy Density: Achieves 250-300 Wh/kg in premium formulations

Table 1: Comparison of Battery Formats

| Parameter | LiPo | Cylindrical | Prismatic |

|---|---|---|---|

| Energy Density (Wh/kg) | 250-300 | 200-250 | 220-270 |

| Thickness Range (mm) | 0.4-10 | 18+ | 5-15 |

| Weight Efficiency | 95% | 85% | 88% |

| Design Flexibility | Excellent | Poor | Moderate |

2. Electrochemical Performance Metrics

Modern LiPo batteries offer significant performance enhancements:

- Cycle Life: 500-800 cycles to 80% capacity (improving at 8% annually)

- Charge Rates: 1C standard, with 3-5C available in high-performance versions

- Self-Discharge: <2% per month (vs. 3-5% in liquid electrolyte batteries)

- Temperature Range: -20°C to 60°C operational (with specialized formulations)

3. Safety Features and Innovations

Advanced safety mechanisms in LiPo technology:

- Gel Polymer Electrolyte: Eliminates leakage risks

- Built-in PTC Protection: Prevents thermal runaway

- CID (Current Interrupt Device): Stops overcurrent situations

- Swelling Detection: New smart circuits alert to potential issues

Market Applications and Industry Adoption

4. Consumer Electronics Dominance

LiPo batteries power 78% of premium portable devices:

- Smartphones: 95% adoption in flagship models

- Wearables: 100% market share in smartwatches

- Tablets/Laptops: 65% penetration in ultra-thin designs

- Drones: 82% of commercial UAVs rely on high-C LiPo packs

5. Emerging Industrial Applications

Expanding into new sectors:

- Medical Devices: 40% CAGR in implantable applications

- IoT Sensors: 5-year lifespan in low-power applications

- Smart Packaging: Disposable batteries for logistics tracking

- Flexible Electronics: Powering rollable displays

6. Automotive and Aerospace Potential

Growing EV and aviation applications:

- EV Auxiliary Systems: 12V LiPo replacing lead-acid

- Urban Air Mobility: Preferred for eVTOL aircraft

- Satellite Systems: Radiation-resistant formulations

Table 2: Market Share by Application (2023)

| Sector | Market Share | Growth Rate |

|---|---|---|

| Consumer Electronics | 68% | 7% CAGR |

| Medical | 12% | 22% CAGR |

| Industrial | 9% | 15% CAGR |

| Automotive | 6% | 35% CAGR |

| Aerospace | 5% | 40% CAGR |

Manufacturing and Supply Chain Dynamics

7. Production Process Innovations

Modern LiPo manufacturing advancements:

- Dry Room Requirements: <1% RH for electrode processing

- Lamination Techniques: Multi-layer stacking precision

- Electrolyte Infusion: Controlled absorption processes

- Formation Cycling: Reduced from 72 to 24 hours

8. Raw Material Considerations

Key components and their impact:

- Aluminum Plastic Film: 35% of packaging cost

- Polymer Electrolyte: 15-20% of total BOM

- High-Purity Foils: Demanding 99.99% purity standards

- Binder Systems: PVDF alternatives reducing costs

9. Global Supply Chain Landscape

Regional production strengths:

- China: 65% of global capacity (CATL, ATL dominance)

- South Korea: Premium cell production (LG Chem, Samsung)

- Japan: Specialty formulations (Sony, Panasonic)

- Europe/N.A.: Emerging pilot lines for local supply

Future Trends and Technological Developments

10. Solid-State Polymer Batteries

Next-generation advancements:

- Energy Density: Projected 400+ Wh/kg by 2027

- Safety: Eliminates flammable components

- Cycle Life: Targeting 1,200+ cycles

- Prototypes: 20 companies in advanced testing

11. Sustainability Initiatives

Eco-friendly developments:

- Bio-Based Polymers: 30% reduction in carbon footprint

- Recycling Breakthroughs: 95% material recovery rates

- Dry Electrode Processing: Eliminating solvent use

12. Smart Battery Integration

IoT-enabled features:

- Embedded Sensors: Real-time health monitoring

- Wireless Charging: Compatible thin-film receivers

- Self-Healing Materials: Microcapsule repair systems

Lithium Ion batteries are divided into Liquid lithium-ion Battery (LIB) and Polymer Lithium-ion Battery (PLB), depending on the electrolyte materials used. The anode and cathode materials used in the polymer lithium ion battery are the same as the liquid lithium ion. The anode materials are divided into lithium cobalt acid, lithium manganese acid, ternary materials and lithium iron phosphate materials. The cathode is graphite. The important difference is the difference in electrolytes. Liquid lithium-ion batteries use a liquid electrolyte, while polymer lithium-ion batteries use a solid polymer electrolyte, which can be either dry or colloidal.

Classify:

(1) Solid polymer electrolyte lithium ion battery

The electrolyte is a mixture of polymer and salt. The battery has low ionic conductivity and can be used at room temperature.

(2) Gel polymer electrolyte lithium ion battery

That is to add plasticizer and other additives in solid polymer electrolyte, so as to improve ionic conductivity, so that the battery can be used at room temperature.

(3) Lithium ion batteries made of polymer positive electrode materials

Conductive polymer is used as positive electrode material, its specific capacity is relatively increased. Because solid electrolyte replaces liquid electrolyte, compared with liquid lithium ion battery, polymer lithium ion battery has the advantages of thinness, arbitrary area and arbitrary shape, etc. Therefore, aluminum-plastic composite film can be used to make the battery shell, so as to improve the specific capacity of the whole battery. Polymer lithium ion battery can also use polymer as a positive electrode material, its mass specific energy will be more than 20% higher than the current liquid lithium ion battery. Lithium-ion Polymer Battery has the characteristics of miniature, thin and lightweight. As a result, LI-polymer batteries will have a growing market share.

Matters needing attention

1.Pay attention to short circuit condition

Lithium Polymer batteries are prone to short circuits during charging. It includes internal short circuit, external short circuit, etc.

Today, though, most lithium-ion batteries have protective circuits against short circuits. And explosion-proof wires. But in a lot of cases, this circuit is not going to work in a lot of situations.

Explosion-proof wire can be used, but also very limited.

2. Do not overcharge

Polymer lithium ion battery, if, charging time is too long, the possibility of expansion will increase.

Lithium is very active and easy to burn. When the battery is charged and discharged, the internal temperature of the battery will continue to rise, and the gas expansion in the activation process will increase the pressure inside the battery to a certain extent. If there is a scar on the shell, it will burst, causing leakage, fire and even explosion. Lithium-ion polymer batteries, on the other hand, only expand.

We must pay attention to safety when using.

-

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More -

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More -

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More -

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More -

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More