What Is a Rechargeable Li-ion Battery: Complete Guide & Industry Insights

When I first started working with lithium-ion batteries over a decade ago, the technical terms and chemistry behind them seemed complex. Today, I’ll explain not just the definition, but the engineering, performance data, key advantages, and real industry applications that matter to decision-makers and buyers alike.

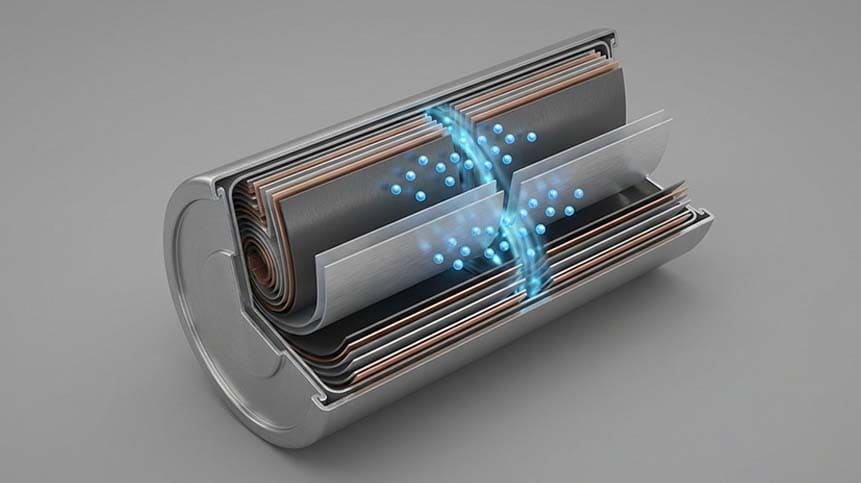

A rechargeable Li-ion battery is a type of secondary battery (rechargeable battery) that stores electrical energy through reversible chemical reactions involving lithium ions moving between the positive (cathode) and negative (anode) electrodes. This technology differs from disposable batteries because it can be charged, discharged, and reused many times, making it ideal for modern electronics, electric vehicles (EVs), and energy storage systems.

Core Definition & How It Works

Rechargeable Battery vs. Primary Battery

A rechargeable battery (also called a secondary cell) stores energy and can be recharged repeatedly, unlike primary (single-use) batteries that are discarded after one use.

Key difference:

-

Primary battery: single discharge → disposal

-

Rechargeable battery: multiple charge/discharge cycles → reuse

Lithium-Ion Battery Technology Explained

A Li-ion battery uses lithium ions (Li⁺) as the charge carriers. During charging, lithium ions are extracted from the cathode material and driven through the electrolyte to the anode. During discharge, the ions flow back to the cathode, releasing electrical energy for the device.

Simplified Workflow

-

Charging forces ions from cathode → anode

-

Discharging forces ions back → cathode

-

This movement of ions creates a flow of electrons — electricity to your device

Why Li-ion Batteries Are Superior

To fully grasp their dominance, it’s crucial to compare Li-ion batteries with other rechargeable types.

Key Advantages Over Other Chemistries

✔ High energy density – stores more energy than NiMH or lead-acid per unit weight

✔ Longer cycle life – many Li-ion cells endure 1,000+ charge cycles under normal conditions

✔ Low self-discharge – retains charge longer when unused

✔ No memory effect – no need for full discharges

✔ Compact & lightweight – ideal for portable electronics

Li-ion Battery Performance Data

Here’s a table summarizing typical field performance:

| Specification | Typical Range | Notes |

|---|---|---|

| Cell nominal voltage | ~3.6–3.7 V | Higher than NiMH/NiCd |

| Energy density | 150–250 Wh/kg | Key for EV & portable tech |

| Cycle life | 500–2000 cycles | Depends on use & temperature |

| Self-discharge rate | ~2–3% per month | Low vs others |

| Capacity fade after 500 cycles | ~12–24% | Typical range observed in tests |

These figures reflect real battery behavior in laboratory and field testing.

Common Applications of Rechargeable Li-ion Batteries

Li-ion technology is now ubiquitous in both consumer and industrial markets.

Consumer Electronics

-

Smartphones, laptops, tablets

-

Cameras and wearable devices

Electric Vehicles (EVs) & Transportation

-

EV battery packs in cars, bikes, scooters

-

High energy density and lightweight design drive adoption in automotive markets

Renewable Energy Storage

-

Grid storage paired with solar/wind power

-

Smooths out intermittent generation

Medical & Industrial Devices

-

Portable medical equipment

-

Robotics and automation systems

These applications reflect the evolving global demand for rechargeable energy storage.

Challenges & Limitations

Despite many benefits, Li-ion batteries have some trade-offs:

Cost

Higher upfront cost than non-rechargeable options.

Thermal & Safety Management

Require protective electronics and temperature control to prevent overheating.

Ageing & Capacity Loss

Capacity gradually decreases with use and time.

Best Practices for Maximum Lifespan

Optimal handling helps extend the usable life of Li-ion batteries:

✅ Avoid deep discharges

✅ Store at partial charge (~40–60%) if unused long-term

✅ Keep cool — extreme temperatures accelerate degradation

References

Wikipedia – Rechargeable battery (definition & types)

Technical battery lifecycle research (capacity fade study)

FAQ – Most Searched Questions

What makes a Li-ion battery rechargeable?

It uses reversible chemical reactions to move lithium ions between electrodes repeatedly — enabling charging and reuse.

How long does a Li-ion battery last?

Most modern Li-ion cells last 500–2000 cycles, equivalent to several years of normal use.

Can you overcharge a Li-ion battery?

Yes — that’s why BMS (battery management systems) are used to prevent overcharge, overheating, or deep discharge.

Are Li-ion batteries safe?

They are safe when paired with proper safety circuits and temperature controls but can be hazardous if damaged or misused.

Conclusion

Today’s rechargeable Li-ion batteries are the backbone of modern portable power — combining high energy density, long cycle life, and practical performance across industries. Whether you’re sourcing cells for a new product or optimizing battery packs for an electric vehicle, understanding their capabilities and limitations is key to success.

If you’d like assistance selecting or customizing Li-ion batteries for your application, contact our technical team at A&S Power. We’re here to help you make informed, performance-oriented decisions.

-

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More -

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More -

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More -

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More -

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More