Why are Aluminum Casings Preferred Over Steel Casings for Lithium-ion Batteries?

The use of aluminum casings instead of steel casings for lithium-ion batteries results from a comprehensive trade-off considering energy density, cost, manufacturing process, electrochemical characteristics, and safety. Overall, aluminum casings provide significant weight reduction advantages and better overall performance for lithium-ion batteries while still fulfilling the basic protection function.

The following is a detailed comparison and analysis:

Core Reasons:

1. Lightweight and Energy Density

This is the primary reason. For consumer electronics (such as mobile phones and laptops) and electric vehicles, energy density—especially gravimetric energy density—is a core competitive advantage.

-

Density comparison:

-

Aluminum: ~2.7 g/cc

-

Steel: ~7.8 g/cc (~2.9 times that of aluminum)

-

Using aluminum casings significantly reduces the weight of the battery pack. The reduction in the "dead weight" of the casing directly translates into an increase in the overall energy density of the battery system.

Impact: Aluminum-cased batteries can have 10%–15% higher energy density than steel-cased batteries, which is crucial for electric vehicles seeking longer range.

2. Processability and Cost

-

Aluminum casings: Good ductility; easy to stamp and stretch form (e.g., square and cylindrical battery casings).

-

Steel casings: Relatively higher processing difficulty and energy consumption.

Aluminum is suitable for large-scale automated production and offers advantages in overall cost (including materials, processing, and transportation).

-

Aluminum price (early Dec 2025): 21,000–22,000 RMB/ton

-

304 stainless steel price: 12,000–13,000 RMB/ton

Although aluminum unit price may be higher than ordinary steel, the system benefits of lightweight and ease of processing offset this cost.

For high-voltage systems (>4.3V), oxidation-resistant 314 stainless steel is required (price: 23,000–24,000 RMB/ton), further increasing steel casing costs compared to aluminum.

3. Electrochemical Stability

High-Voltage Electrolyte Compatibility:

-

Aluminum casing: In LiPF6 electrolyte, aluminum forms a dense AlF3 passivation film under high voltage (>4.3V), inhibiting electrolyte corrosion and ensuring long-term stability.

-

Steel casing: Ordinary steel (Fe) oxidizes easily under high voltage, requiring stainless steel (e.g., 316) for high-voltage applications. Adding chromium, nickel, and molybdenum increases costs.

4. Mechanical Strength and Safety

-

Aluminum casing: Lower strength but with ductility.

-

Steel casing: High strength and toughness.

Implications:

-

Steel casings provide better mechanical protection, resisting crushing and puncture.

-

Aluminum casings compensate for lower strength by increasing thickness (e.g., prismatic batteries) or using reinforcing ribs.

-

For severe mechanical abuse (e.g., special tools), steel casings are preferred.

-

Aluminum casings crack at pre-designed explosion-proof valves, making pressure release safer and more controllable.

5. Heat Dissipation Performance

-

Aluminum casing: High thermal conductivity (~237 W/(m·K))

-

Steel casing: Low thermal conductivity (~50 W/(m·K))

Impact: Aluminum casings conduct heat faster, aiding battery thermal management, improving cycle life and safety, especially under abuse conditions.

Different Types of Battery Casing Choices

Cylindrical Batteries (e.g., 18650, 21700, 4680)

-

Mainstream: Steel casings (e.g., Panasonic cells in early Tesla models).

-

Reason: Small diameter requires high strength to withstand radial expansion.

-

Steel + internal insulation design is mature and reliable.

-

-

Aluminum-cased cylindrical batteries exist for weight-sensitive applications.

Prismatic Batteries

-

Almost all use aluminum casings.

-

Aluminum thickness compensates for lower strength.

-

Advantages: Lightweight, easy processing, good heat dissipation.

-

Common in EV battery packs and energy storage systems.

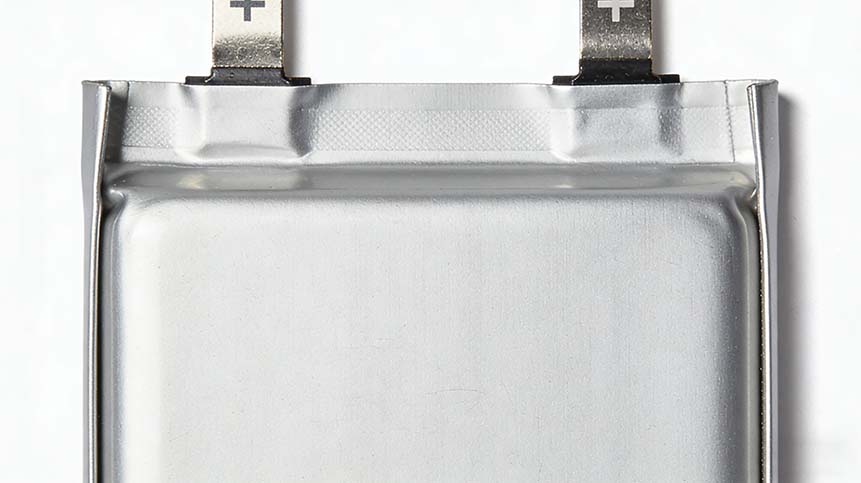

Pouch Batteries

-

Use aluminum-plastic composite film.

-

Structure: Thin aluminum (~40 μm) core barrier + nylon (PET) outside + polypropylene (CPP) inside for heat sealing.

-

Benefits: Lightest packaging, highest energy density.

-

Requires mechanical support from battery pack structure.

FAQ

Q1: Why are aluminum casings preferred over steel in lithium-ion batteries?

Aluminum casings are preferred because they are significantly lighter than steel, which increases the overall energy density of lithium-ion batteries. They also offer better heat dissipation, excellent compatibility with high-voltage electrolytes, easier manufacturing, and lower system-level costs—making them ideal for EVs, energy storage systems, and consumer electronics.

Q2: Do aluminum battery casings improve energy density?

Yes. Aluminum has a density of about 2.7 g/cm³, compared to steel’s 7.8 g/cm³. Replacing steel with aluminum reduces the “dead weight” of the casing, allowing aluminum-cased batteries to achieve approximately 10–15% higher gravimetric energy density.

Q3: Are steel casings safer than aluminum casings?

Steel casings provide higher mechanical strength and puncture resistance, which is beneficial in extreme mechanical abuse scenarios. However, aluminum casings offer better thermal conductivity and controlled pressure-release behavior, which improves overall safety in most mainstream applications.

Q4: Why are prismatic lithium-ion batteries almost always aluminum-cased?

Prismatic batteries use aluminum casings because thickness and structural design can compensate for aluminum’s lower strength while maximizing its advantages—light weight, easy stretch forming, good heat dissipation, and cost efficiency. This makes aluminum ideal for EV and energy storage battery packs.

Q5: Why do many cylindrical batteries still use steel casings?

Cylindrical batteries like 18650 and 21700 cells often use steel casings because their small diameter requires very high radial strength to withstand internal expansion forces. Steel provides superior mechanical rigidity in this specific geometry.

Q6: Is aluminum compatible with high-voltage lithium-ion batteries?

Yes. In LiPF₆-based electrolytes, aluminum forms a stable passivation layer (AlF₃) at voltages above 4.3V, which protects it from corrosion. This makes aluminum highly suitable for modern high-voltage lithium-ion battery systems.

Q7: What is the lightest lithium-ion battery casing option?

Pouch batteries using aluminum-plastic composite film are the lightest option. They offer the highest energy density but require external structural support within the battery pack.

Conclusion

The use of aluminum-plastic composite film for 3C batteries and aluminum casings for large cells is an optimized choice for lithium-ion battery development. It meets the core demands of consumer electronics, EVs, and energy storage industries for:

-

High energy density

-

Good heat dissipation

-

Electrochemical stability

-

Safety

-

Controllable cost

Aluminum casings, with their irreplaceable advantages of lightweight and good thermal conductivity, have prevailed over heavier, stronger steel casings. Steel casings are still used in special applications requiring extreme mechanical strength or where weight is not critical.

-

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More -

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More -

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More -

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More -

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More